Active carbon preparation method using deinked sludge as raw material

An activated carbon preparation and activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of large environmental impact, high temperature toxic gas, and high activation temperature, and achieve rapid adsorption, excellent adsorption capacity, increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

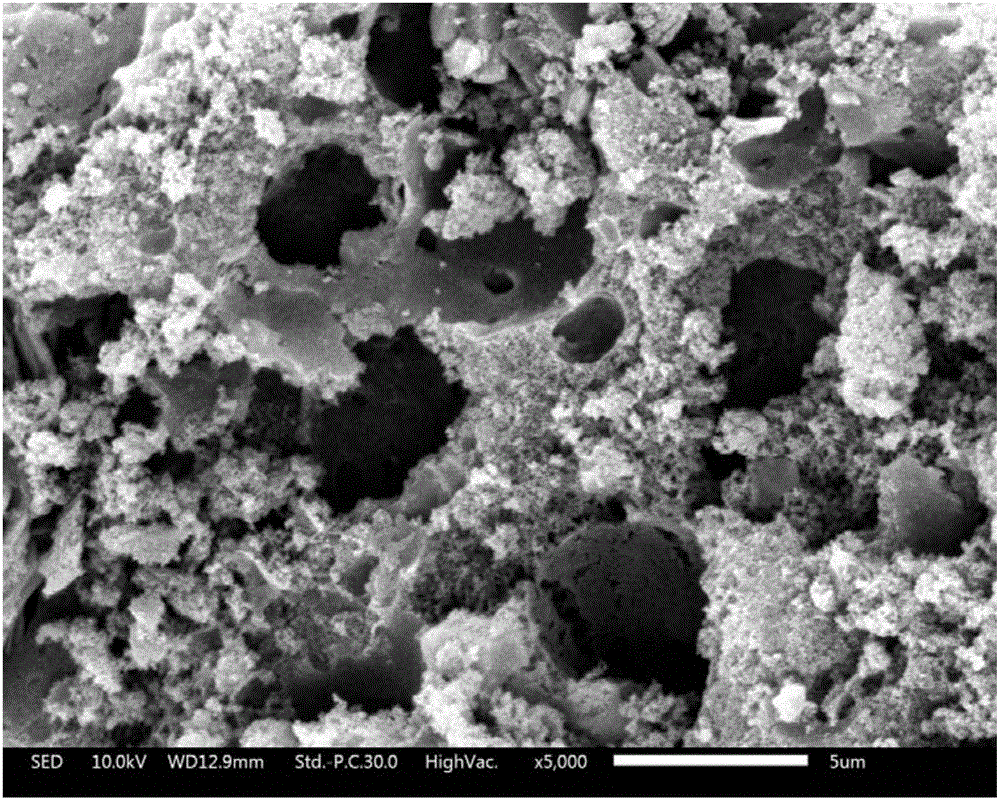

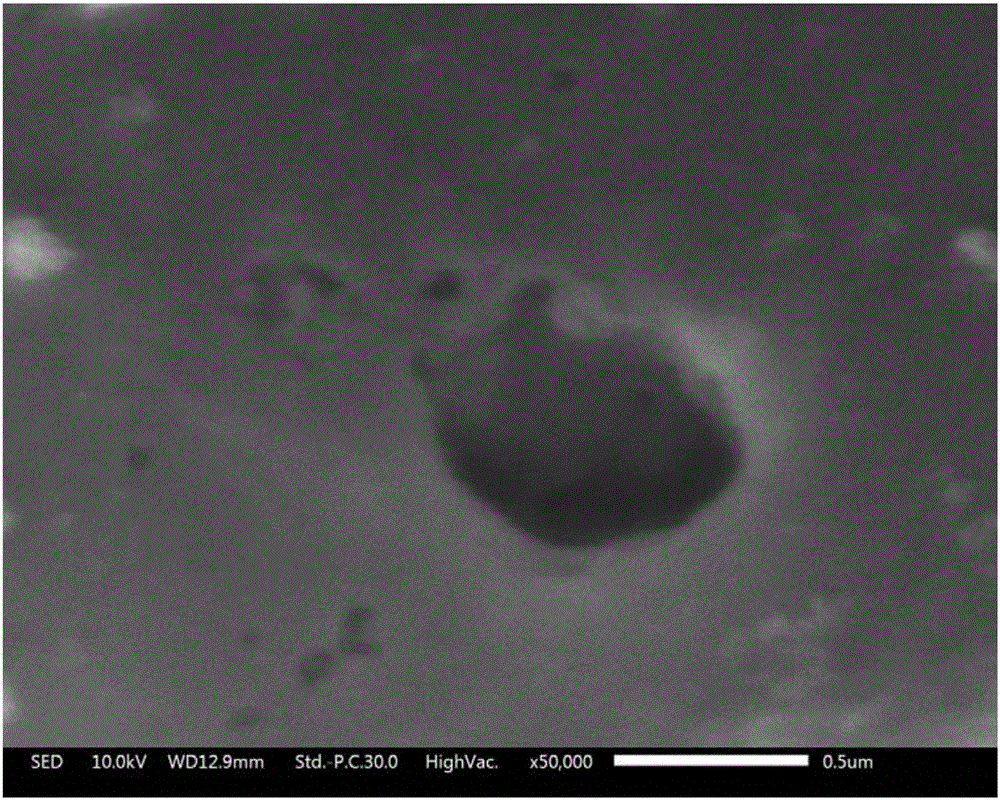

Image

Examples

Embodiment 1

[0014] Raw materials: deinking slag 1kg (in terms of dry matter), water content 20%; phosphoric acid 5kg, concentration 80% (the water content of deinking slag has been taken into account when preparing and adding phosphoric acid solution, so as to avoid deinking slag. Moisture affects the dilution of phosphoric acid solution, so the water content of deinking slag has been included in the above-mentioned 5kg phosphoric acid, correspondingly, the above-mentioned phosphoric acid concentration is also the concentration calculation result of considering the moisture of deinking slag, following examples 2 and 3 in both).

[0015] Preparation steps:

[0016] (1) Phosphoric acid solution is added in the container that fills deinking slag, stirs and mixes for 15 minutes, makes phosphoric acid solution and deinking slag fully mix, then container is sealed and stands still for 24 hours;

[0017] (2) Continue heating and activating the mixture of deinking slag and phosphoric acid under ...

Embodiment 2

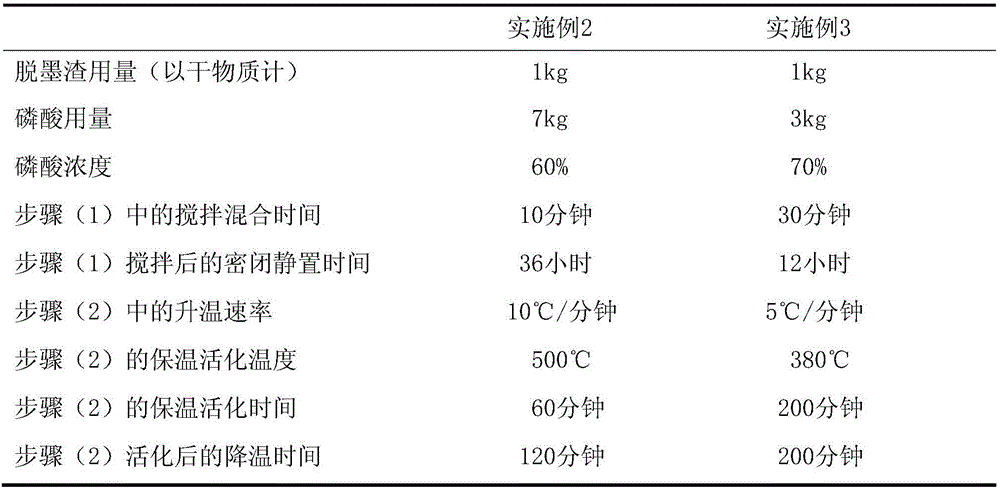

[0019] The raw materials and preparation steps used in Example 2 and Example 3 are basically the same as in Example 1, only the amount of raw materials and some reaction conditions in the preparation steps are different, as listed in Table 1.

[0020] The raw material consumption that table 1 embodiment 2 and embodiment 3 adopt and the reaction condition of each preparation step

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com