A kind of heat-resistant polyethylene resin composition and its application

A technology of heat-resistant polyethylene and resin composition, applied in the field of polymer materials, can solve the problems of weak pressure resistance, unstable long-term hydraulic resistance, etc., and achieve the effect of excellent long-term pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

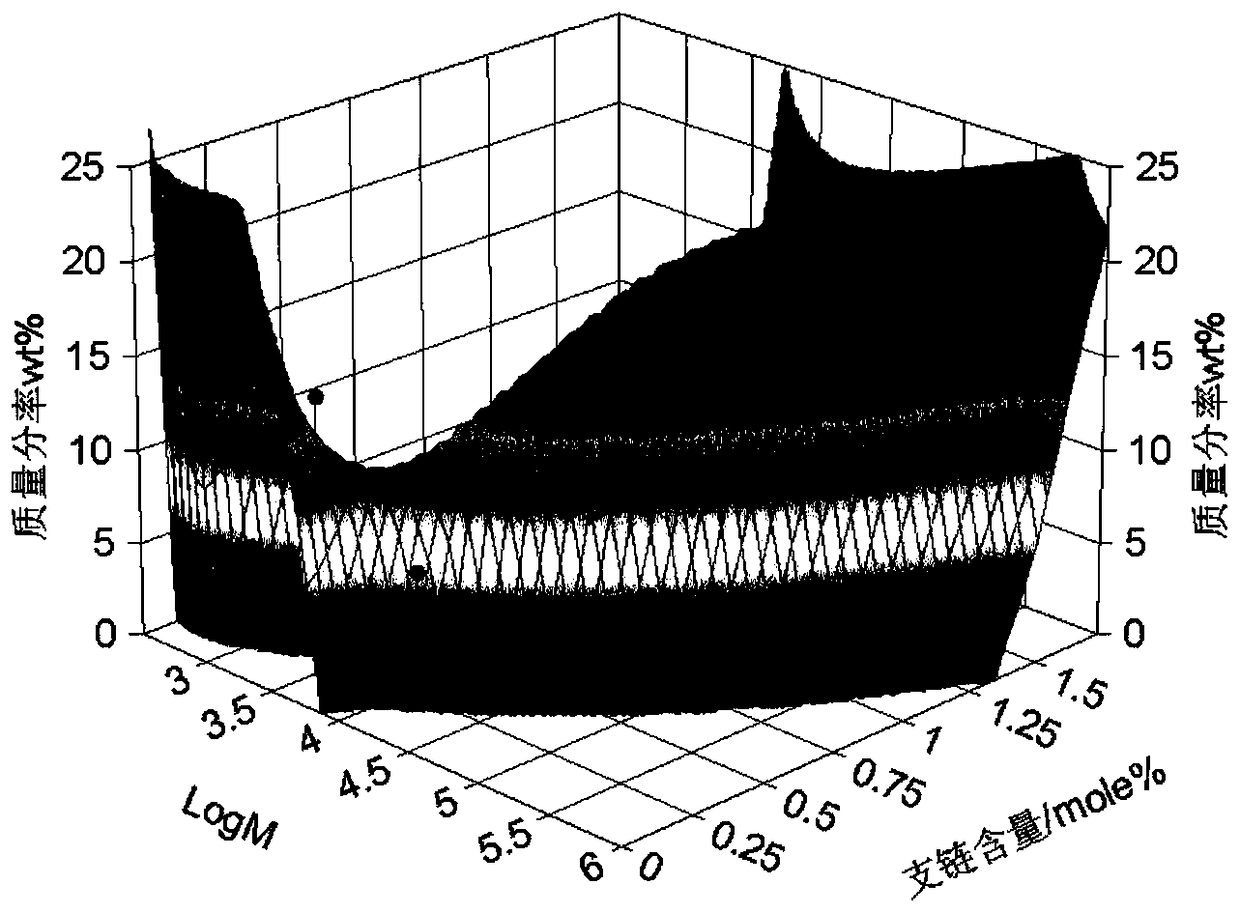

Image

Examples

preparation example Construction

[0031] The preparation method of heat-resistant polyethylene composition is as follows:

[0032] Put heat-resistant polyethylene resin, antioxidant, processing rheological agent, and acid absorbing agent into a high-speed mixer according to the weight ratio, stirring speed 1000-2000 rpm, stirring time 15min, stirring temperature: room temperature. Add the uniformly mixed powder into the twin-screw extruder for kneading, and set the temperature of each heating section of the extruder to 140°C, 190°C, 200°C, 200°C, 200°C, 190°C, and preheat Heat for more than 30 minutes, and wait for the temperature of each heating section of the extruder to rise to the set value. The sample to be tested is put into an extruder, melted, plasticized, extruded and granulated to prepare a heat-resistant polyethylene composition.

Embodiment 1

[0034] The heat-resistant polyethylene composition is prepared by the following method:

[0035] (1) 100 parts polyethylene resin (melt flow rate is 0.46g / 10min (190°C, 5kg), density 0.947g / cm 3 , weight average molecular weight 235000, molecular weight distribution width 20.9, melting temperature 135°C, crystallinity 64%, wafer thickness 35nm;

[0036] (2) 0.12 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0037] (3) 0.05 parts of 1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene;

[0038] (4) 0.10 parts of 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl)-s-triazine-2,4,6-(1H,3H,5H)-trione;

[0039] (5) 0.03 parts of three (2,4-di-tert-butylphenyl) phosphite;

[0040] (6) 0.05 parts of binary copolymers of vinylidene fluoride and hexafluoropropylene;

[0041] (7) 0.05 parts of calcium stearate.

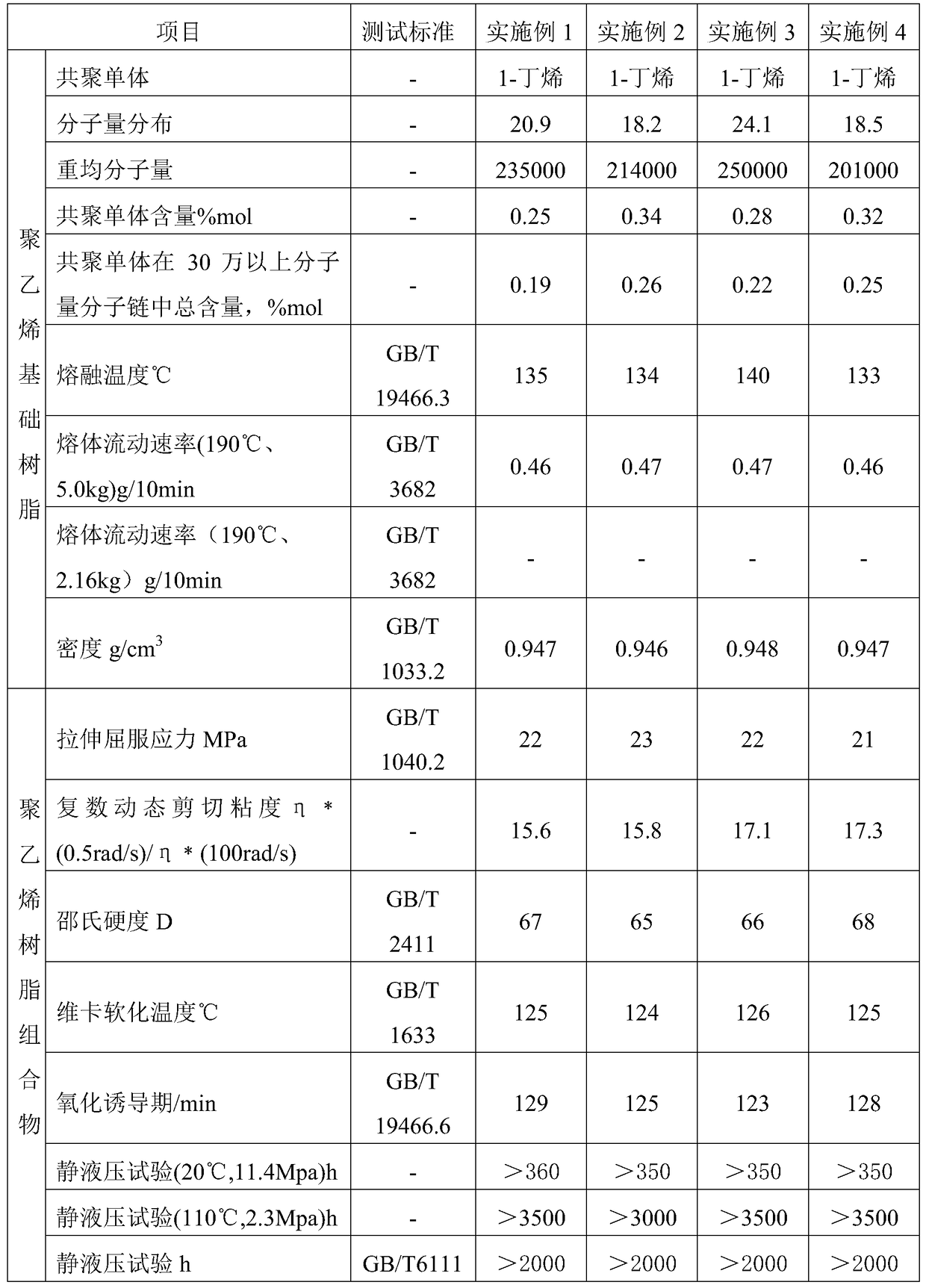

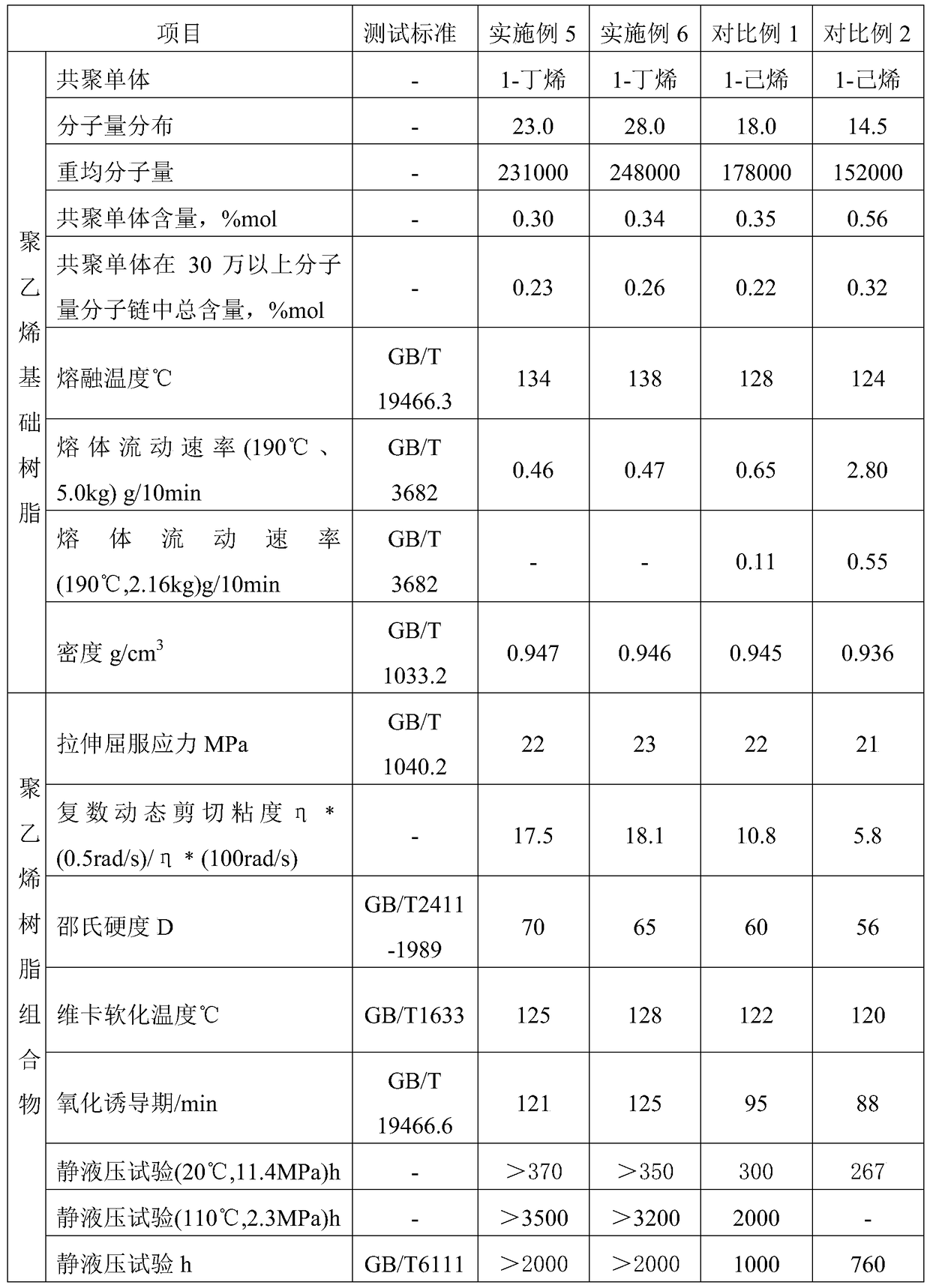

[0042] The above-mentioned polyethylene resin composition was processed and performance measured, and the perform...

Embodiment 2

[0044] The heat-resistant polyethylene composition is prepared by the following method:

[0045] (1) 100 parts of polyethylene resin (melt flow rate is 0.47g / 10min (190°C, 5kg), density 0.946g / cm 3 , weight average molecular weight 214000, molecular weight distribution width 18.2, melting temperature 134°C, crystallinity 64%, wafer thickness 33nm;

[0046] (2) 0.10 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester;

[0047] (3) 0.05 parts of three (2,4-di-tert-butylphenyl) phosphite;

[0048] (4) 0.15 parts of dilauryl thiodipropionate are composed;

[0049] (5) 0.01 part of a binary copolymer of vinylidene fluoride and hexafluoropropylene;

[0050] (6) 0.1 part of zinc oxide.

[0051] The above-mentioned polyethylene resin composition was processed and performance measured, and the performance parameters and the performance of the polyethylene resin composition are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com