Method for increasing yield of camellia seed oil extracted with aqueous enzymatic method

A technology of camellia seed oil and water enzymatic method, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of increased production cost, chemical organic reagent residue, quality decline, etc., achieve low energy consumption, increase yield, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2-4

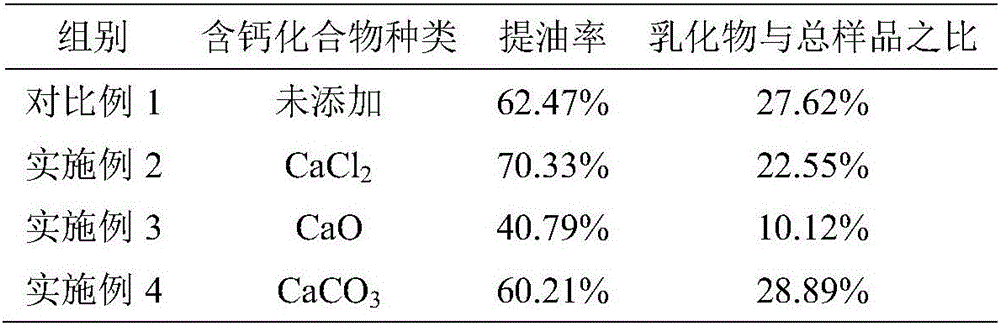

[0029] Example 2-4: Effect of Calcium Compound Type on Oil Extraction Rate and Emulsion to Total Sample Ratio

[0030] Take 5 grams of tea seed powder (40 mesh) in a 100ml beaker, add distilled water at a material-to-liquid ratio of 1:8, inactivate the enzyme in a 90°C water bath for 10 minutes, adjust the pH to 6.0 with 0.1mol / L NaOH solution, and add 0.1% ( w / v, g / mL) cellulase, hydrolyze at 50°C for 1 h, then adjust the pH to 9.0 with 2mol / L NaOH solution, add n Ca2+ :n 皂素 = 1:1 calcium-containing compound (types of calcium-containing compound include calcium chloride, calcium carbonate or calcium oxide), and 0.1% (v / v, mL / mL) Alcalase 2.4L alkaline protease, enzymolysis at 60°C for 4h. After enzymatic hydrolysis, inactivate the enzyme in a water bath at 90°C for 10 minutes; cool to room temperature, centrifuge the sample solution (8000rpm, 30min, 4°C), collect the clear oil in the upper layer and the emulsion in the middle layer, and calculate the ratio of clear oil and e...

Embodiment 5-8

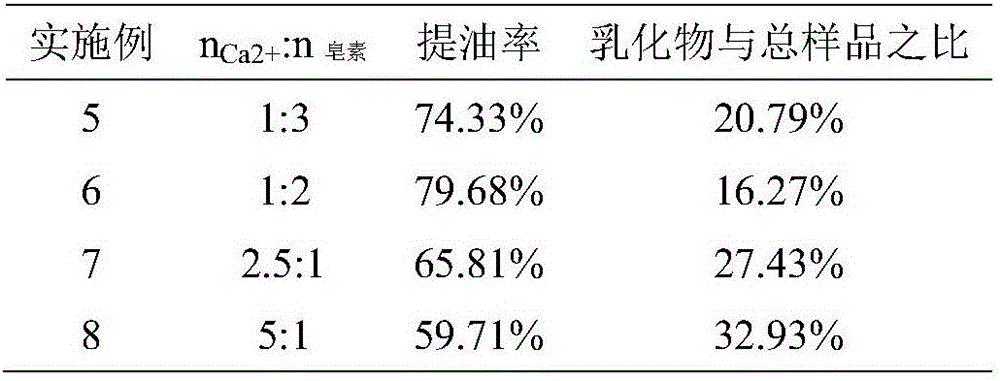

[0034] Examples 5-8: Ca 2+ Effect of Addition Amount on Oil Extraction Rate and Ratio of Emulsion to Total Sample

[0035] Take 5 grams of tea seed powder (40 mesh) in a 100ml beaker, add distilled water at a material-to-liquid ratio of 1:8, inactivate the enzyme in a 90°C water bath for 10 minutes, adjust the pH to 6.0 with 0.1mol / L NaOH solution, and add 0.1% ( w / v, g / mL) cellulase, hydrolyze at 50℃ for 1h, then adjust the pH to 9.0 with 2mol / L NaOH solution, add n Ca2+ :n 皂素=1:3; 1:2; 2.5:1; 5:1 0.1mol / L calcium chloride, and 0.1% (v / v, mL / mL) Alcalase 2.4L alkaline protease, 60°C for 4h, After enzymatic hydrolysis, inactivate the enzyme in a water bath at 90°C for 10 minutes; cool to room temperature, centrifuge the sample solution (8000rpm, 30min, 4°C), collect the clear oil in the upper layer and the emulsion in the middle layer, and calculate the ratio of clear oil and emulsion to the total sample. The results are listed in Table 2.

[0036] Table 2 Ca 2+ Effect of...

Embodiment 9-12

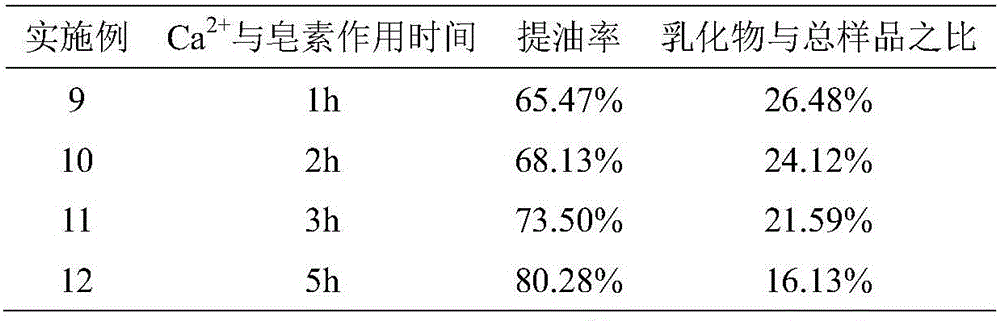

[0039] Examples 9-12: Ca 2+ Effect of reaction time with saponin on oil extraction rate and ratio of emulsified product to total sample

[0040] Take 5 grams of tea seed powder (40 mesh) in a 100ml beaker, add distilled water at a material-to-liquid ratio of 1:8, inactivate the enzyme in a 90°C water bath for 10 minutes, adjust the pH to 6.0 with 0.1mol / L NaOH solution, and add 0.1% ( w / v, g / mL) cellulase, hydrolyze at 50°C for 1 h, then adjust the pH to 9.0 with 2mol / L NaOH solution, add 0.1% (v / v, mL / mL) Alcalase 2.4L alkaline protease, 60 ℃ enzymatic hydrolysis for 4h to extract, add n Ca2+ :n 皂素 =1:2 0.1mol / L calcium chloride (calculated as Ca 2+ The reaction time with saponin is 5h, 4h, 3h, 2h, 1h). After enzymatic hydrolysis, inactivate the enzyme in a water bath at 90°C for 10 minutes; cool to room temperature, centrifuge the sample solution (8000rpm, 30min, 4°C), collect the clear oil in the upper layer and the emulsion in the middle layer, and calculate the ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com