Application of a cotpyp metalloporphyrin coordination polymer material

A technology of coordination polymers and metalloporphyrins, applied in the direction of material electrochemical variables, etc., to achieve the effects of short response time, excellent catalytic performance, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ①The TPyP ligand was synthesized according to the reference (Xie Minghua, Design Synthesis and Catalytic Performance of Metal-Organic Framework Materials Based on Functional Ligands[J], Zhejiang University, 2011, Ph.D. Dissertation), and the synthesis yield was 15%.

[0024] ②The TPyP ligand was synthesized according to the above references, the reaction time was changed from 2 hours to 2.5 hours, and the synthesis yield was 34%.

[0025] ③The TPyP ligand was synthesized according to the above references, the reaction time was changed from 2 hours to 2.5 hours, and Al2O3 was replaced by chromatographic silica gel, and the synthesis yield was 57%.

[0026] ④ Synthesize the TPyP ligand according to the above references, change the reaction time from 2 hours to 2.5 hours, replace Al2O3 with chromatography silica gel, perform chromatography, and replace rotary evaporation (CHCl 3 :methanol=1:1), the synthetic yield is 60%.

[0027] ⑤ Synthesize TPyP ligands according to th...

Embodiment 2

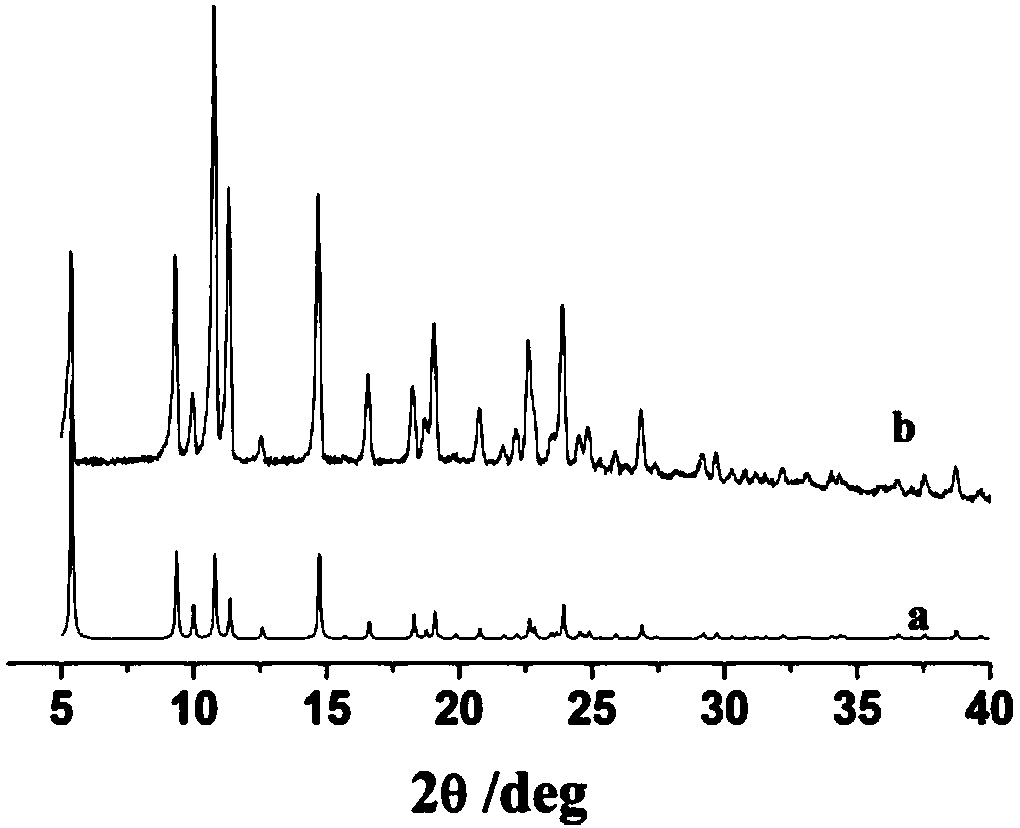

[0032] ①12.43mg TPyP and 23.84mg CoCl 2 ·6H 2 O dissolves in CH 3 COOH (4mL), H 2 O (4 mL), the resulting mixture was added to a 25 mL reactor, and then the reactor was placed in an oven at 120° C. for 3 d, no product was obtained. Filter and wash with DMF, H 2 O, washed with EtOH until the filtrate was colorless, and then dried in an oven at 50°C.

[0033] ②12.43mg TPyP and 23.84mg CoCl 2 ·6H 2 O dissolves in CH 3 COOH (4mL), H 2 O (4 mL) and KOH (1M, 0.1 mL) were added to the resulting mixture into a 25 mL reactor, and then the reactor was placed in an oven at 120° C. for 3 days to obtain a purple powder. Filter and wash with DMF, H 2 O and EtOH were washed until the filtrate was colorless, and then dried in an oven at 50° C., the yield was 37%.

[0034] ③12.43mg TPyP and 23.84mg CoCl 2 ·6H 2 O dissolves in CH 3 COOH (4mL), H 2 O (4 mL) and KOH (1M, 0.2 mL) were added to the resulting mixture into a 25 mL reactor, and then the reactor was placed in an oven at 1...

Embodiment 3

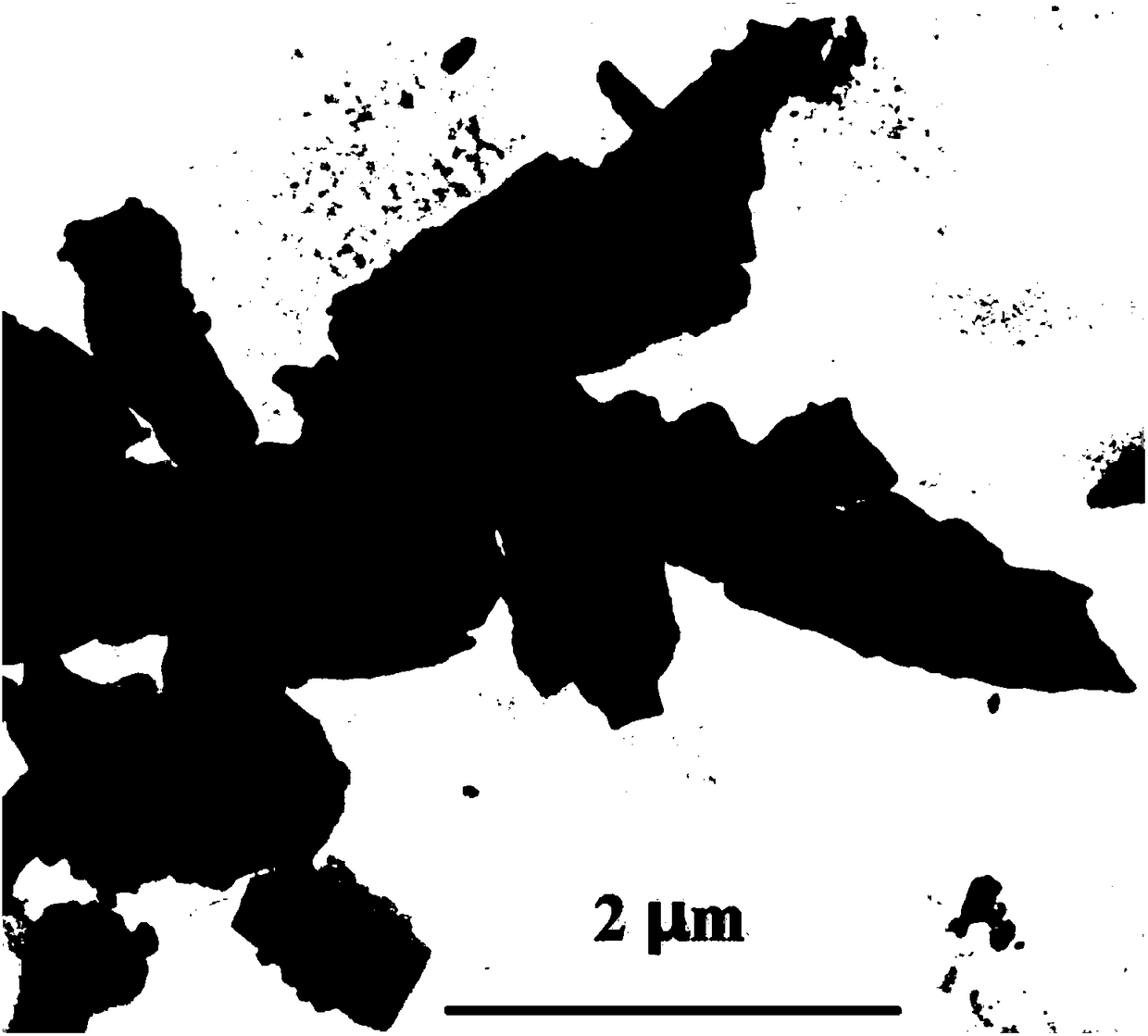

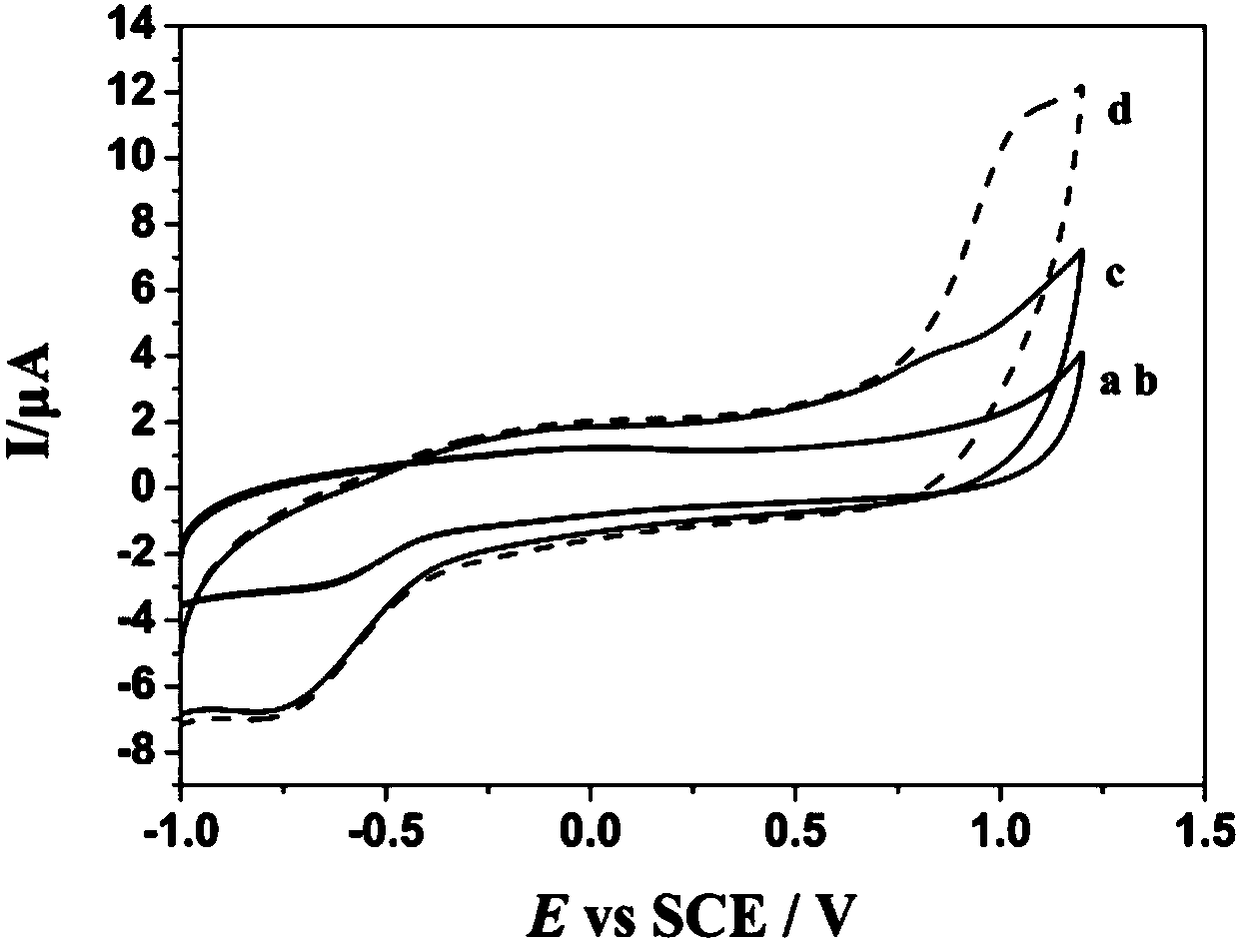

[0040] ①Put 0.20g of graphite powder and 2mg of CoTPyP in an agate mortar and grind for about 20min, make them fully mixed, then add 0.115mL of liquid paraffin and grind to a uniform paste. Then the prepared paste was filled into a plastic tube with an inner diameter of 3 mm, compacted, and a copper wire was inserted as a wire to obtain a CoTPyP carbon paste electrode.

[0041] ② 0.20g of graphite powder and 2mg of CoTPyP were ground in an agate mortar for about 30 minutes, mixed thoroughly, and then 0.115mL of liquid paraffin was added and ground to a uniform paste. Then the prepared paste was filled into a plastic tube with an inner diameter of 3 mm, compacted, and a copper wire was inserted as a wire to obtain a CoTPyP carbon paste electrode. Bare carbon paste electrodes without CoTPyP can also be prepared by the same method. CoTPyP / CPE was tested by cyclic voltammetry in the range of -1.0-1.2V.

[0042] ③ 0.30g of graphite powder and 2mg of CoTPyP were ground in an agate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com