Preparation method of nickel cobalt oxide nanorod composite material wrapped by carbon having microspheric grading structure

A hierarchical structure and composite material technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve problems such as poor conductivity and poor cycle stability, and achieve improved stability, improved conductivity, improved stability and The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

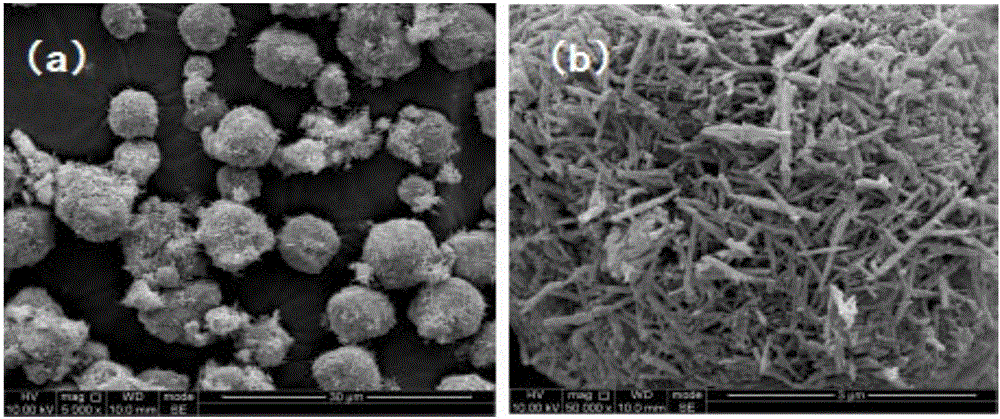

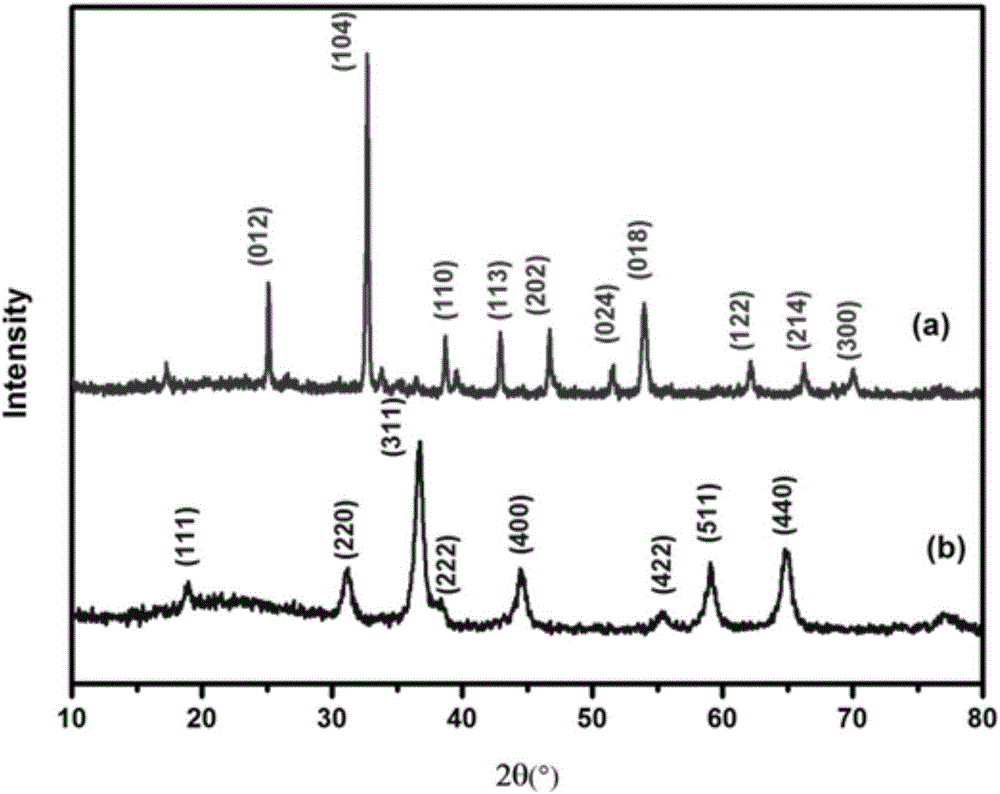

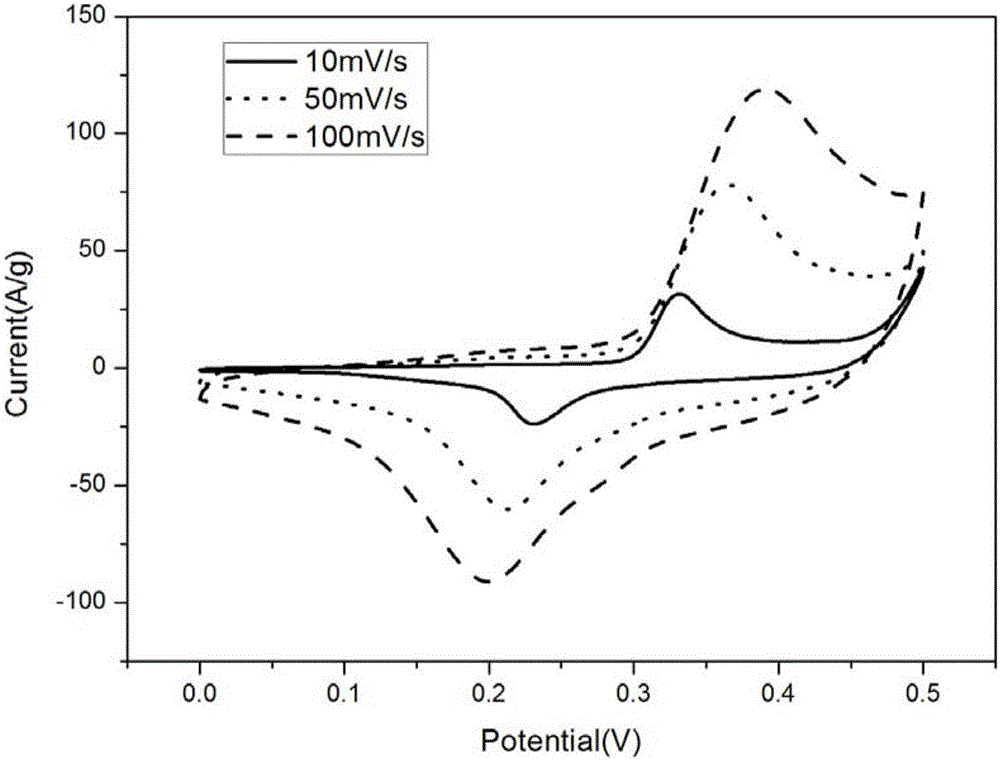

[0029] A method for preparing a microspherical hierarchical structure carbon-wrapped nickel cobalt oxide nanorod composite material, comprising the following steps:

[0030] (1) ethylene glycol and water are mixed with a volume ratio of 1.5:1 to prepare a mixed solvent;

[0031] (2) Weigh 0.375g of nickel chloride, 0.375g of cobalt chloride, 1.985g of urea and 0.125g of diphthalonitrile and uniformly disperse them in the 50ml mixed solvent prepared in step (1), ultrasonically disperse for 1 hour to form a mixed solution;

[0032] (3) Pour the mixed solution prepared in step (2) into the liner of the crystallization kettle, and crystallize at 200° C. for 5 hours;

[0033] (4) When the crystallization kettle is lowered to room temperature, suction filtration, cleaning, and drying are performed successively to obtain nickel phthalocyanine / cobalt carbonate composite material;

[0034] (5) Calcining the nickel phthalocyanine / cobalt carbonate composite material prepared in step (4...

Embodiment 2

[0041] A method for preparing a microspherical hierarchical structure carbon-wrapped nickel cobalt oxide nanorod composite material, comprising the following steps:

[0042] (1) ethylene glycol and water are mixed with a volume ratio of 1.5:1 to prepare a mixed solvent;

[0043] (2) Weigh 0.375g of nickel chloride, 0.375g of cobalt chloride, 1.985g of urea and 0.125g of diphthalonitrile and uniformly disperse them in the 50ml mixed solvent prepared in step (1), ultrasonically disperse for 1 hour to form a mixed solution;

[0044] (3) Pour the mixed solution prepared in step (2) into the liner of the crystallization kettle, and crystallize at 180° C. for 8 hours;

[0045] (4) When the crystallization kettle is lowered to room temperature, suction filtration, cleaning, and drying are performed successively to obtain nickel phthalocyanine / cobalt carbonate composite material;

[0046] (5) Calcining the nickel phthalocyanine / cobalt carbonate composite material prepared in step (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com