White adhesive for shoe upper coating sponge and preparation method thereof

A kind of adhesive, white technology, applied in the direction of adhesive types, natural rubber adhesives, polymer adhesive additives, etc., can solve the problem of yellowing of the adhesive paste, improve the anti-permeability, improve the viscosity Combined effect, the effect of eliminating surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

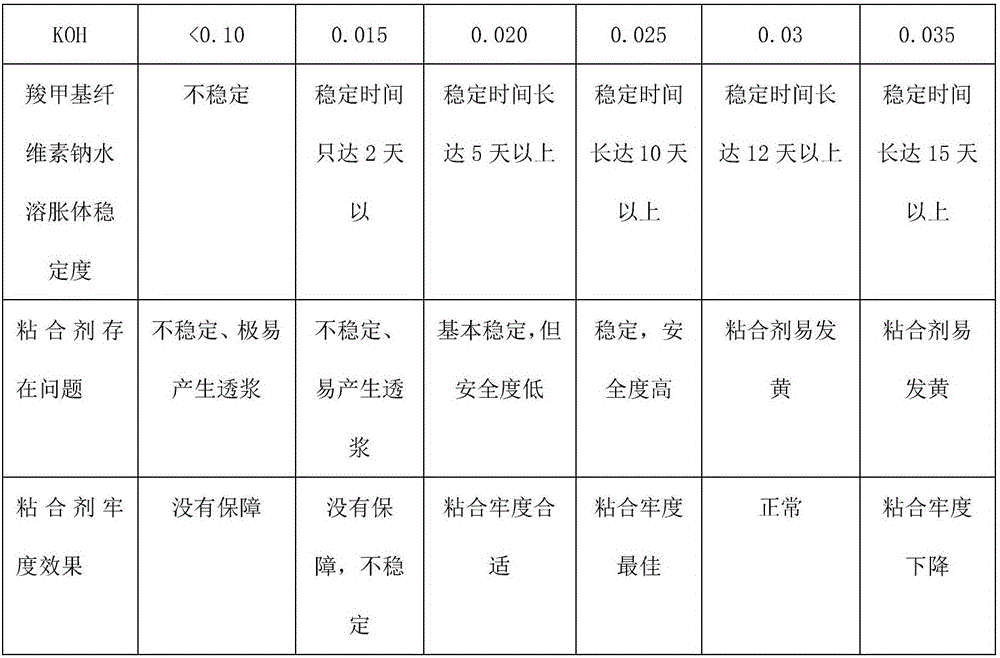

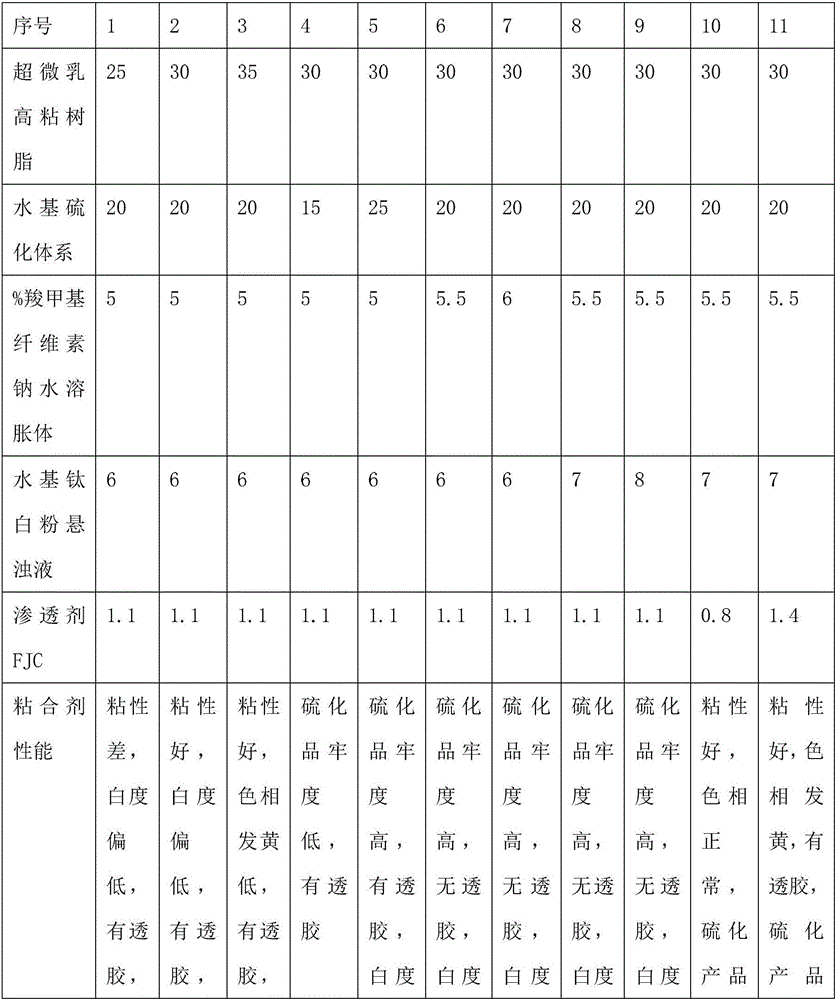

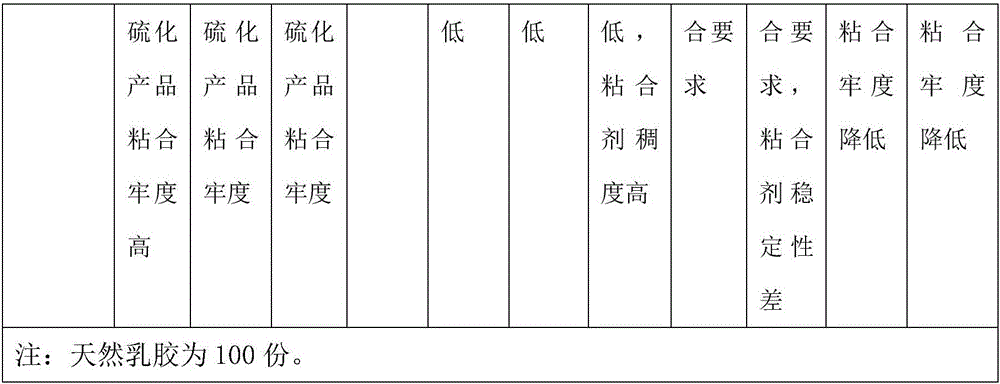

[0060] Embodiments of the present invention: white adhesive for shoe upper bag sponge, calculated in parts by weight, it includes 100 parts of natural latex, 30 parts of supermicroemulsion high-viscosity resin, 5.5 parts of 5% sodium carboxymethylcellulose water-swellable body , 20 parts of water-based vulcanization system, 7 parts of water-based titanium dioxide suspension, 5 parts of Pingpingjia aqueous solution with a mass percentage concentration of 50%, and 1.1 parts of penetrant JFC are the raw materials for preparation; every 20 parts of water-based vulcanization system includes 1 1 part of potassium hydroxide, 1 part of sulfur, 1.5 parts of vulcanization accelerator TMTD, 1.2 parts of nano-zinc oxide, 0.5 parts of diffusing agent, 0.3 parts of anti-aging agent MB, 0.5 parts of anti-aging agent SP-C, 0.5 parts of casein anhydride and 13.5 parts of soft water Composition; every 5.5 parts of 5% sodium carboxymethylcellulose water-swellable body includes 5.2 parts of soft w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com