Carbon-coating orthorhombic system nanometer rod shape Nb2O5 material and manufacturing method thereof

An orthorhombic, nano-rod-like technology, applied in the field of lithium-ion batteries, can solve the problems of low material capacity and poor rate performance, and achieve the effects of improving reaction speed, performance and low capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] One aspect of the present invention provides a carbon-coated orthorhombic nanorod-shaped Nb 2 o 5 The preparation method of the material is characterized in that the preparation method comprises the following steps:

[0037] Step 1: Take a certain amount of oleic acid and trioctylamine, and mix the oleic acid and trioctylamine evenly according to the volume ratio of 3:16 to prepare mixture A;

[0038] Step 2: Add a certain amount of ammonium niobate oxalate into the above mixture A, and stir to obtain solution B;

[0039] Step 3: The solution B obtained in step 2 is subjected to microwave hydrothermal reaction, wherein the temperature range is set at 150°C-170°C, and the reaction time is set at 30min-1h;

[0040] Step 4: centrifuging the product obtained after the reaction in step 3, thereby obtaining a solid-liquid mixture C with a small amount of residual solvent in the lower layer;

[0041] Step 5: Put the solid-liquid mixture C obtained in step 4 into a tube furn...

Embodiment 1

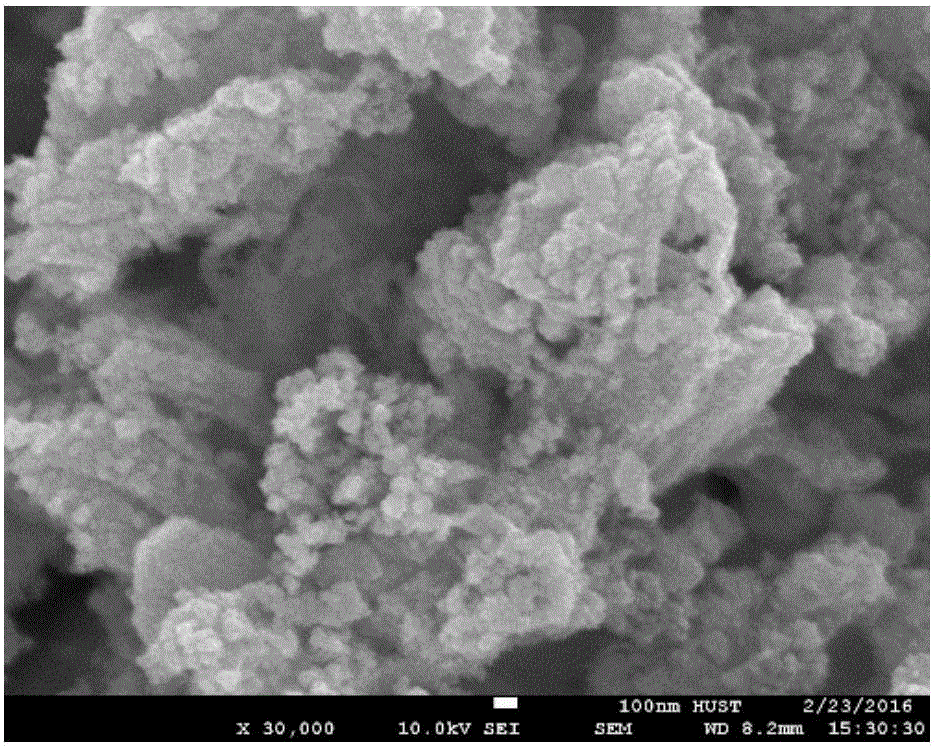

[0048] Stir the oleic acid and trioctylamine with a volume ratio of 3:16 until they are evenly mixed, then add 1.65mM ammonium niobate oxalate to the solution, and stir overnight; put the above solution in a microwave hydrothermal reaction kettle for microwave Hydrothermal reaction, in which the temperature is set at 150°C, and the reaction time is set at 30 minutes; the product after the microwave hydrothermal reaction is centrifuged to obtain a solid-liquid mixture with a small amount of residual solvent in the lower layer; the above mixture is placed in a porcelain Put it in a boat and put it into a tube furnace for calcination treatment, wherein the atmosphere is Ar atmosphere, the calcination temperature is 800°C, and the calcination time is set to 1h.

Embodiment 2

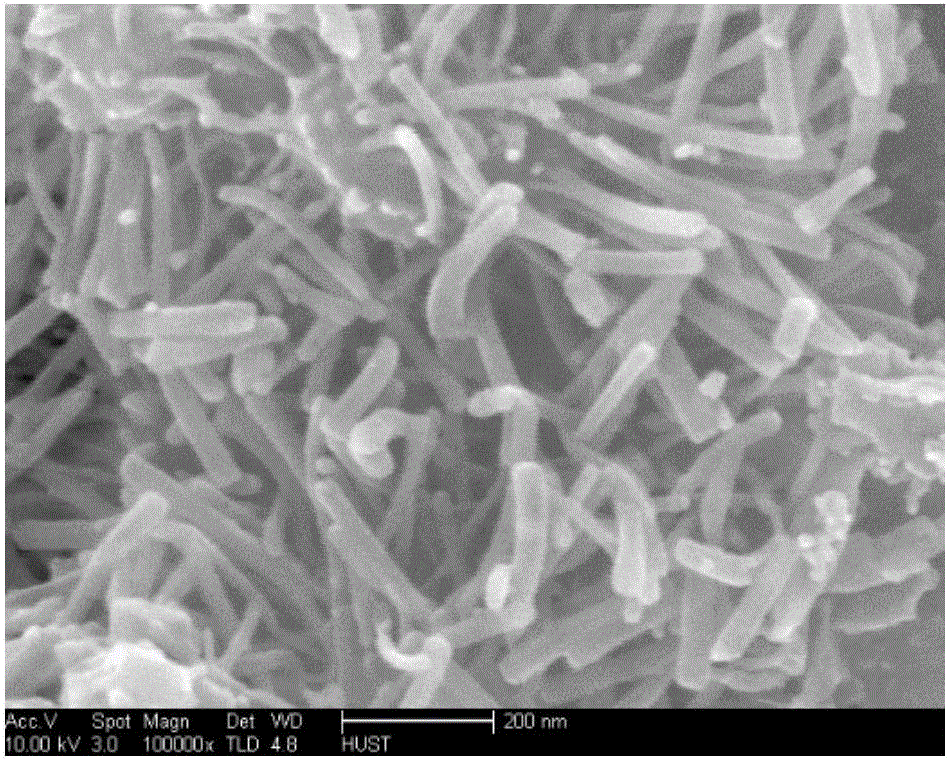

[0050] Stir the oleic acid and trioctylamine with a volume ratio of 3:16 until they are evenly mixed, then add 1.65mM ammonium niobate oxalate to the solution, and stir overnight; put the above solution in a microwave hydrothermal reaction kettle for microwave Hydrothermal reaction, in which the temperature is set at 150 ° C, and the reaction time is set at 1 h; the product after the microwave hydrothermal reaction is centrifuged to obtain a solid-liquid mixture with a small amount of residual solvent in the lower layer; the above mixture is placed in a porcelain Put it in a boat and put it into a tube furnace for calcination treatment, wherein the atmosphere is Ar atmosphere, the calcination temperature is 800°C, and the calcination time is set to 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com