A kind of sodium magnesium secondary battery and preparation method thereof

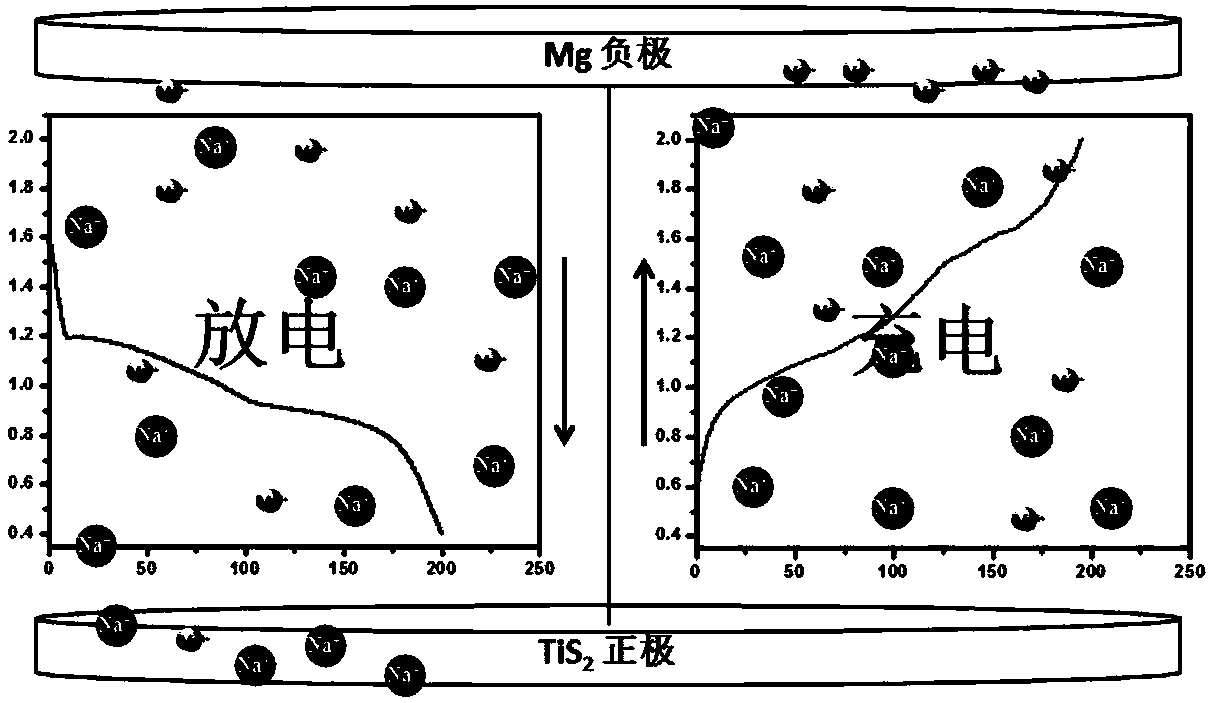

A magnesium secondary battery and electrolyte technology, applied in the field of sodium magnesium secondary battery and its preparation, can solve the problems of slow magnesium ion intercalation process, large polarization, poor rate cycle performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the present invention, the preparation method of the positive electrode preferably includes the following steps: (a) adding TiS 2 , conductive aid and binding agent are mixed to obtain mixed slurry; (b) coating the mixed slurry obtained in the step (a) on a substrate to obtain a primary positive electrode; (c) drying the primary positive electrode After pressing, the positive electrode is obtained.

[0040] The present invention preferably uses TiS 2 , the conductive auxiliary agent and the binder are mixed to obtain a mixed slurry. In the present invention, the amount and type of raw materials in the mixed slurry are in accordance with the TiS mentioned in the above technical scheme 2 , conductive additives and binders. The present invention has no special requirements on the mixing method, and a mixing method well known to those skilled in the art can be used. The present invention preferably adopts the mode of manual agitation to mix described TiS 2 , conduct...

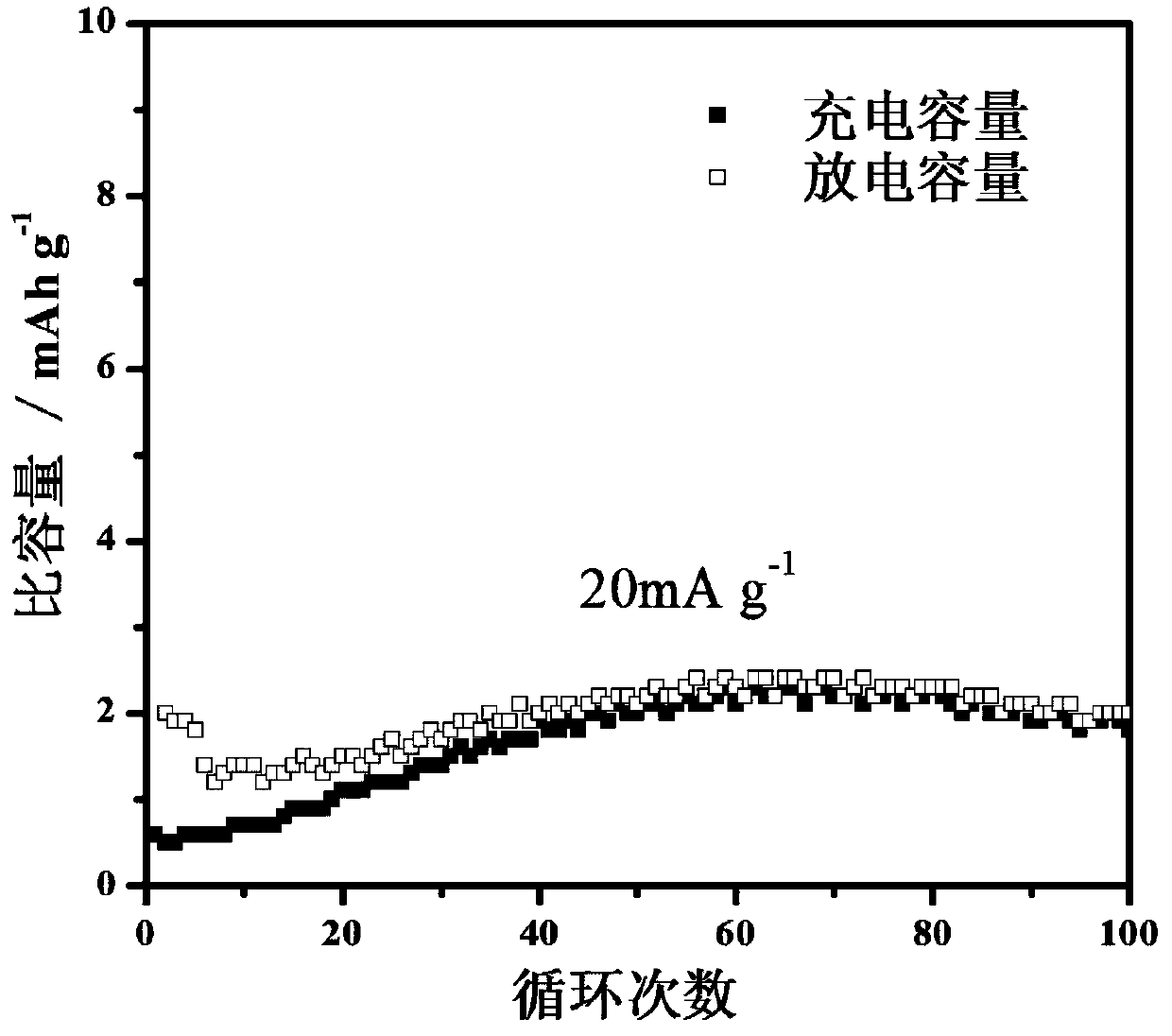

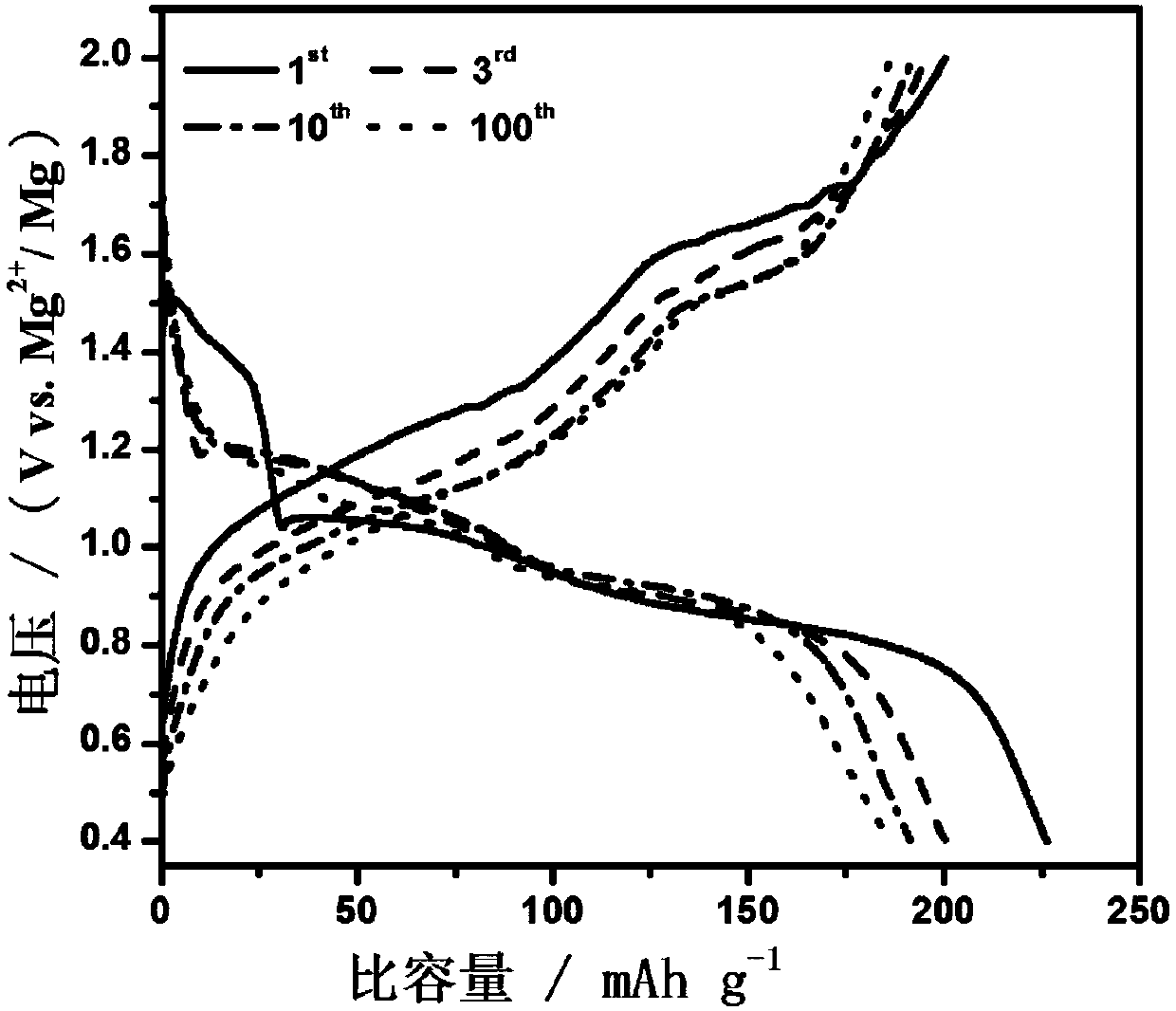

Embodiment 1

[0052] Preparation of electrolyte solution: put 1mol of sodium borohydride and 0.1mol of magnesium borohydride into a conical flask in the glove box, and add diethylene glycol dimethyl ether, under the action of a magnetic stirrer at 500r / min Stirring at high speed for 12 hours to obtain an electrolyte, the concentration of sodium borohydride in the obtained electrolyte is 1 mol / L, and the concentration of magnesium borohydride is 0.1 mol / L.

[0053] Preparation of positive electrode material: according to the mass ratio of 75:10:7 commercial TiS 2 , acetylene black and polyvinylidene fluoride are mixed in an agate mortar by manual stirring to obtain a mixed slurry, wherein the stirring rate is 100r / min, and the stirring time is 5min; the obtained mixed slurry is coated with On a 9μm stainless steel substrate, the amount of mixed slurry coating is based on the area of the substrate as 3mg / cm 2 Then, the stainless steel substrate coated with the mixed slurry was dried for 10...

Embodiment 2

[0057] Prepare the electrolyte: put 0.5mol of sodium borohydride and 0.1mol of magnesium borohydride into the conical flask in the glove box, and add diethylene glycol dimethyl ether, under the action of a magnetic stirrer at 150r / min Stir at a high speed for 24 hours to obtain an electrolytic solution, the concentration of sodium borohydride in the obtained electrolytic solution is 0.5 mol / L, and the concentration of magnesium borohydride is 0.1 mol / L.

[0058] Preparation of positive electrode material: according to the mass ratio of 70:20:10 commercial TiS 2 , natural graphite and polyacrylic acid are mixed in an agate mortar by manual stirring to obtain a mixed slurry, wherein the stirring rate is 300r / min, and the stirring time is 5min; the obtained mixed slurry is coated with 10μm graphite On the foil substrate, the amount of mixed slurry coating is based on the area of the substrate as 3mg / cm 2 Then, the graphite foil substrate coated with the mixed slurry was dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com