Nickel nitride@nitrogen doped porous carbon sphere material and preparation and application thereof in lithium-sulfur battery

A nitrogen-doped porous carbon and lithium-sulfur battery technology, which is applied in lithium batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of unfavorable practical promotion of lithium-sulfur batteries, small specific surface area of catalysts, and insufficient reaction interface. Achieve the effects of inhibiting the shuttle effect, good electrochemical performance, and excellent capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

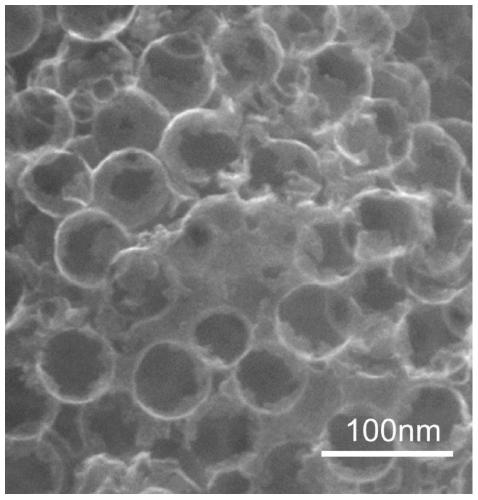

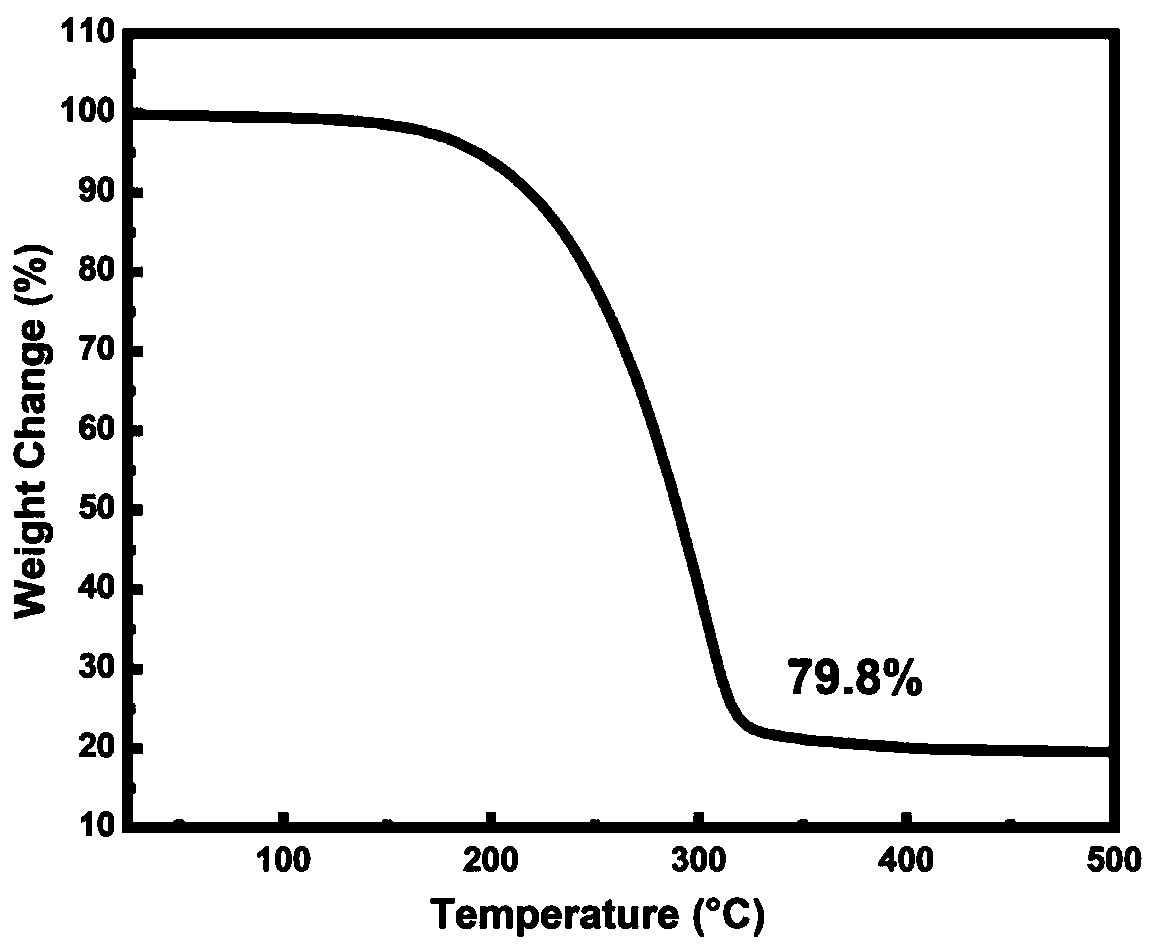

[0071] 5 kg of starch, 5 kg of 50nm SiO 2 Template dispersion, 80 grams of nickel acetate and 50 grams of sodium dodecylsulfonate were added to 10L of deionized water, stirred at 80°C for 5 hours to prepare a uniform spray slurry, and the slurry was added to the spray pyrolysis via a peristaltic pump After the system, under the ammonia atmosphere, set the spray volume through the spray system to 5mL / min, and the atomization pressure to 5MPa. The spray solution is sprayed and pyrolyzed in the high-temperature pyrolysis furnace at 1000°C, and the spray pyrolysis products are collected. The product was mixed with 5 L of 5 mol / l sodium hydroxide solution, and the silica template was washed away in a reaction kettle at 80 degrees Celsius. The material is a uniform spherical particle with a particle size of about 5 microns and a pore volume of 2.18 cm 3 / g, the specific surface area is 1668m 2 / g, from figure 1 It can be seen that the inside of the spherical particle is composed ...

Embodiment 2

[0075] 5 kg of starch, 5 kg of 500nm SiO 2 Template dispersion, 80 grams of nickel acetate and 50 grams of sodium dodecylsulfonate were added to 10L of deionized water, stirred at 80°C for 5 hours to prepare a uniform spray slurry, and the slurry was added to the spray pyrolysis via a peristaltic pump After the system, under the ammonia atmosphere, set the spray volume through the spray system to 50mL / min, and the atomization pressure to 35MPa. The spray solution is sprayed and pyrolyzed in the high-temperature pyrolysis furnace at 1000°C, and the spray pyrolysis products are collected. The product was mixed with 5 L of 5 mol / l sodium hydroxide solution, and the silica template was washed away in a reaction kettle at 80 degrees Celsius. The material is a uniform spherical particle with a particle size of about 25 microns, and a pore volume of 2.21 cm 3 / g, the specific surface area is 1748m 2 / g, the interior of spherical particles is composed of hollow carbon with a diamete...

Embodiment 3

[0078] 5 kg of starch, 5 kg of 150nm SiO 2Template dispersion, 400 g of nickel acetate and 50 g of sodium dodecylsulfonate were added to 10 L of deionized water, stirred at 80°C for 5 hours to prepare a uniform spray slurry, and the slurry was added to the spray pyrolysis via a peristaltic pump After the system, under the ammonia atmosphere, set the spray volume through the spray system to 20mL / min, and the atomization pressure to 20MPa. The spray solution is sprayed and pyrolyzed in the high-temperature pyrolysis furnace at 1000°C, and the spray pyrolysis products are collected. The product was mixed with 5 L of 5 mol / l sodium hydroxide solution, and the silica template was washed away in a reaction kettle at 80 degrees Celsius. The material is uniform spherical particles with a particle size of about 10 microns and a pore volume of 1.64 cm 3 / g, the specific surface area is 1356m 2 / g, the interior of the spherical particle is composed of hollow carbon with a diameter of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com