Grafted solid acid catalyst, preparation method thereof and application of grafted solid acid catalyst in saccharification process of lignocellulose

A lignocellulosic and catalyst technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem that the catalytic activity needs to be further improved, the density of acidic active sites is small, and the catalyst efficiency is limited, etc. problem, to achieve good catalytic effect, high selectivity, good catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]A kind of preparation method of graft type carbon-based solid acid catalyst that the application proposes, comprises the following steps:

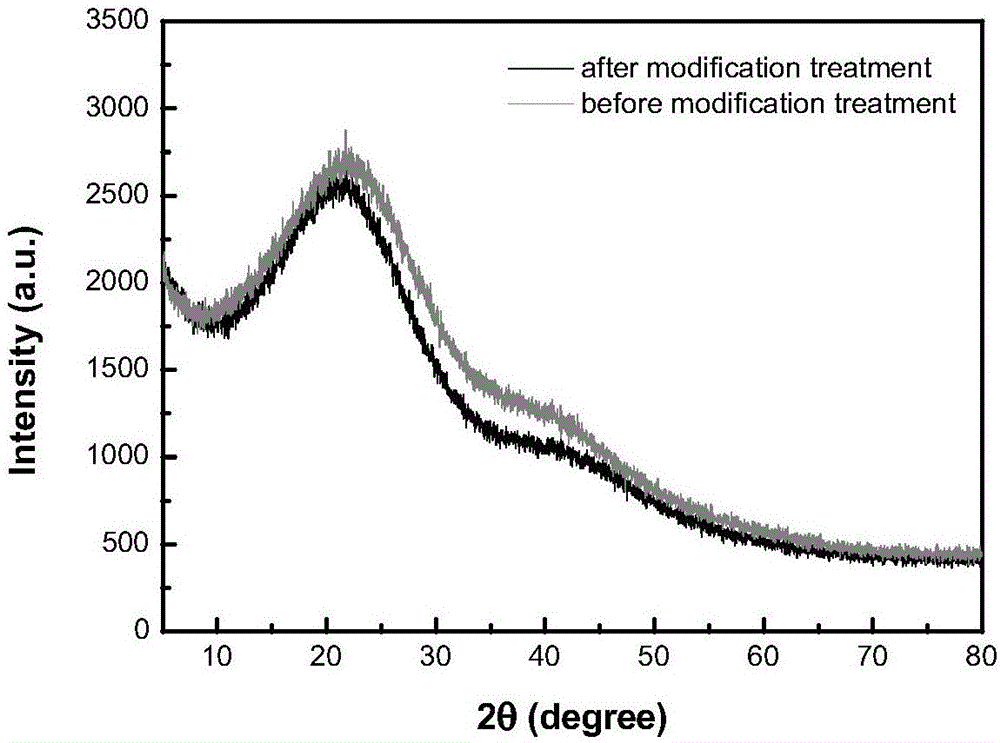

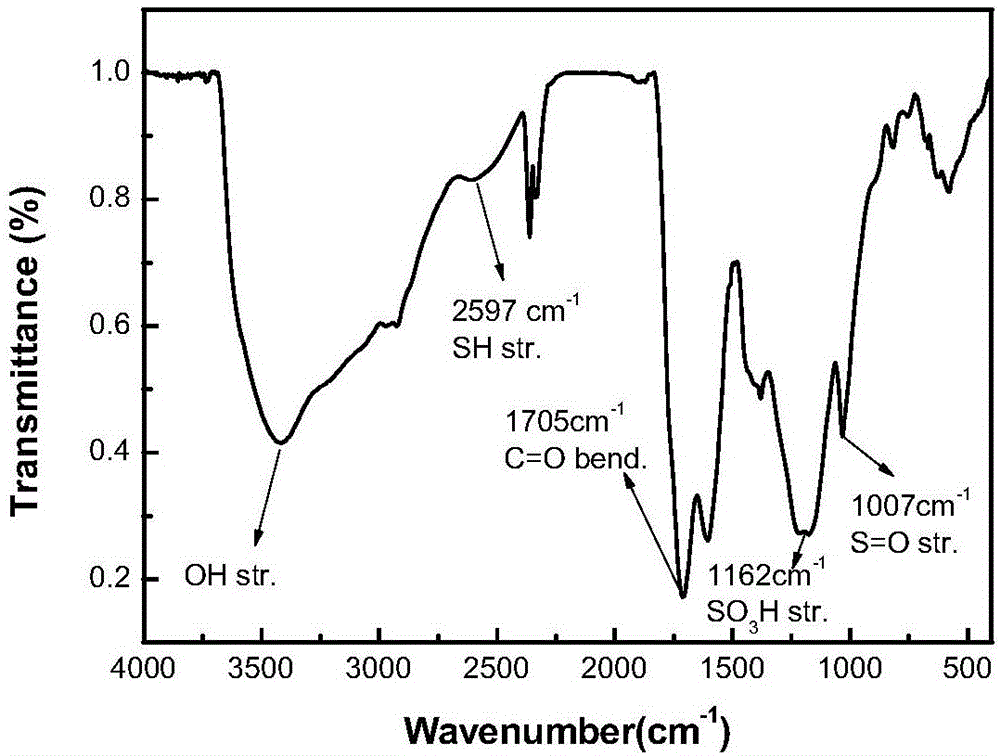

[0038] (1) Preparation of crude carbon-based solid acid catalyst: mix lignocellulosic biomass carbon-based material and sulfonating agent with a mass ratio of 1 / 10 to 10, place the uniformly mixed material in a reaction vessel, Carbonize at a reaction temperature of 120-240°C for 1-36 hours, put the carbonized black solid at high temperature, grind, wash and dry, and the dried black solid is the crude carbon-based solid acid catalyst;

[0039] (2) Oxidative modification of the crude carbon-based solid acid catalyst: the crude carbon-based solid acid catalyst obtained in step (1) and the oxidant are mixed at a solid-to-liquid ratio of 1 / 100 to 1 / 10, at 50 to 60 The reaction is carried out at a temperature of 0.5° C. for 0.5 to 3 hours. After the reaction is completed, a black solid is obtained by filtering and isolating. The black sol...

Embodiment 1

[0041] Glucose and p-toluenesulfonic acid with a mass ratio of 3:1 were ball-milled in a ball mill for 2 hours to mix thoroughly, and then hydrothermally carbonized in a 100mL polytetrafluoroethylene-lined autoclave at 120°C for 24 hours to obtain black For the solid, put it in a muffle furnace at 180°C for 24 hours to remove the small molecular compounds adsorbed on the surface, grind it, wash it repeatedly with deionized water higher than 80°C until the washing liquid is neutral, and collect the solid in an oven at 105°C After drying for 4 hours, a crude carbon-based solid acid catalyst was prepared.

[0042] In the thick-walled pressure-proof bottle of 150mL, add 2g above-mentioned and make crude carbon-based solid acid catalyst and 100mL mass fraction be 30% H 2 o 2 (The density is approximately 1g·cm -3 ) aqueous solution in an oil bath at 50°C for 1 hour, after the oxidation reaction was completed, filter and separate, collect the filter residue, and dry it in an oven ...

Embodiment 2

[0045] Starch and p-toluenesulfonic acid with a mass ratio of 1:10 were ball-milled in a ball mill for 2 hours to mix thoroughly, and then hydrothermally carbonized in a 100mL polytetrafluoroethylene-lined autoclave at 240°C for 1 hour to obtain black For the solid, put it in a muffle furnace at 180°C for 24 hours to remove the small molecular compounds adsorbed on the surface, grind it, wash it repeatedly with deionized water higher than 80°C until the washing liquid is neutral, and collect the solid in an oven at 105°C After drying for 4 hours, a crude carbon-based solid acid catalyst was prepared.

[0046] Add 1g of the crude carbon-based solid acid catalyst and 100mL of 30% H 2 o 2 The aqueous solution was heated in an oil bath at 50°C for 0.5h. After the oxidation reaction was completed, it was separated by filtration, and the filter residue was collected and dried overnight in an oven at 105°C to obtain a modified grafted carbon-based solid acid catalyst.

[0047] Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com