Preparation method of high-purity benzoyl peroxide

A technology for the purity of benzoyl peroxide and benzoyl chloride, which is applied in the field of preparation of benzoyl peroxide, can solve the problems of low product purity, material punching, high production energy consumption, etc., and achieves high reaction safety and crystallization. Large particles, mild response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

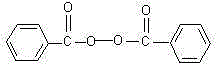

Image

Examples

Embodiment 1

[0027] A preparation method of high-purity benzoyl peroxide, the preparation of high-purity benzoyl peroxide is completed through a synthesis process and a purification process; the specific steps are as follows:

[0028] (1) Synthesis process:

[0029] a. Add 15kg of 30% hydrogen peroxide into a 50L reactor, start stirring, then add 9.3kg of ammonium bicarbonate, slowly add 15kg of benzoyl chloride dropwise, the temperature in the reactor is 20 degrees Celsius, and the reaction time is 2.5 hours;

[0030] b. filter the reaction solution after the reaction, filter to obtain a filter cake, filter the cake in a mixed solvent of 15kg ethanol and 15kg of clear water and wash for 20 minutes, filter;

[0031] c. After beating and washing with 30kg of clear water for 10 minutes, repeat the beating and washing for 3 times;

[0032] d. Finally, rinse with 30kg of clear water, filter and dry to obtain 15.79kg of white benzoyl peroxide crude product;

[0033] (2) Purification process: ...

Embodiment 2

[0039] A preparation method of high-purity benzoyl peroxide, the preparation of high-purity benzoyl peroxide is completed through a synthesis process and a purification process; the specific steps are as follows:

[0040] (1) Synthesis process:

[0041] a. Add 22kg of 30% hydrogen peroxide into a 50L reactor, start stirring, then add 13.5kg of ammonium bicarbonate, slowly add 15kg of benzoyl chloride dropwise, the temperature in the reactor is 30 degrees Celsius, and the reaction time is 3.5 hours;

[0042] b. filter the reaction solution after the reaction, filter to obtain a filter cake, filter the cake in a mixed solvent of 30kg ethanol and 30kg of clear water and wash for 40 minutes, filter;

[0043] c. After beating and washing with 45kg of clear water for 20 minutes, repeat the beating and washing for 3 times;

[0044] d. finally rinse with 45kg of clear water, filter and dry, and obtain the white benzoyl peroxide crude product;

[0045] (2) Purification process:

[0...

Embodiment 3

[0051] A preparation method of high-purity benzoyl peroxide, the preparation of high-purity benzoyl peroxide is completed through a synthesis process and a purification process; the specific steps are as follows:

[0052] (1) Synthesis process:

[0053] a. Add 18kg of 30% hydrogen peroxide into a 50L reactor, start stirring, then add 10.2kg of ammonium bicarbonate, slowly add 15kg of benzoyl chloride dropwise, the temperature in the reactor is 25 degrees Celsius, and the reaction time is 3 hours;

[0054] b. filter the reaction solution after the reaction, filter to obtain a filter cake, and filter the filter cake in a mixed solvent of 22.5kg ethanol and 22.5kg of clear water for beating and washing for 30 minutes, and filter;

[0055] c. After beating and washing with 37.5kg of clear water for 15 minutes, repeat the beating and washing for 3 times;

[0056] d. finally rinse with 37.5kg of clear water, filter and dry to obtain 15.82kg of white benzoyl peroxide crude product; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com