Carbon nano tube ionic liquid composite material, and preparation method and application thereof to remove carboxymethyl lysine in soy sauce brewing

An ionic liquid and carbon nanotube technology, applied in food science and other directions, can solve the problems of limiting the effective use of ionic liquids, small two-phase interface, difficult recycling, etc., to improve the extraction rate and recycling rate, low cost, and removal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

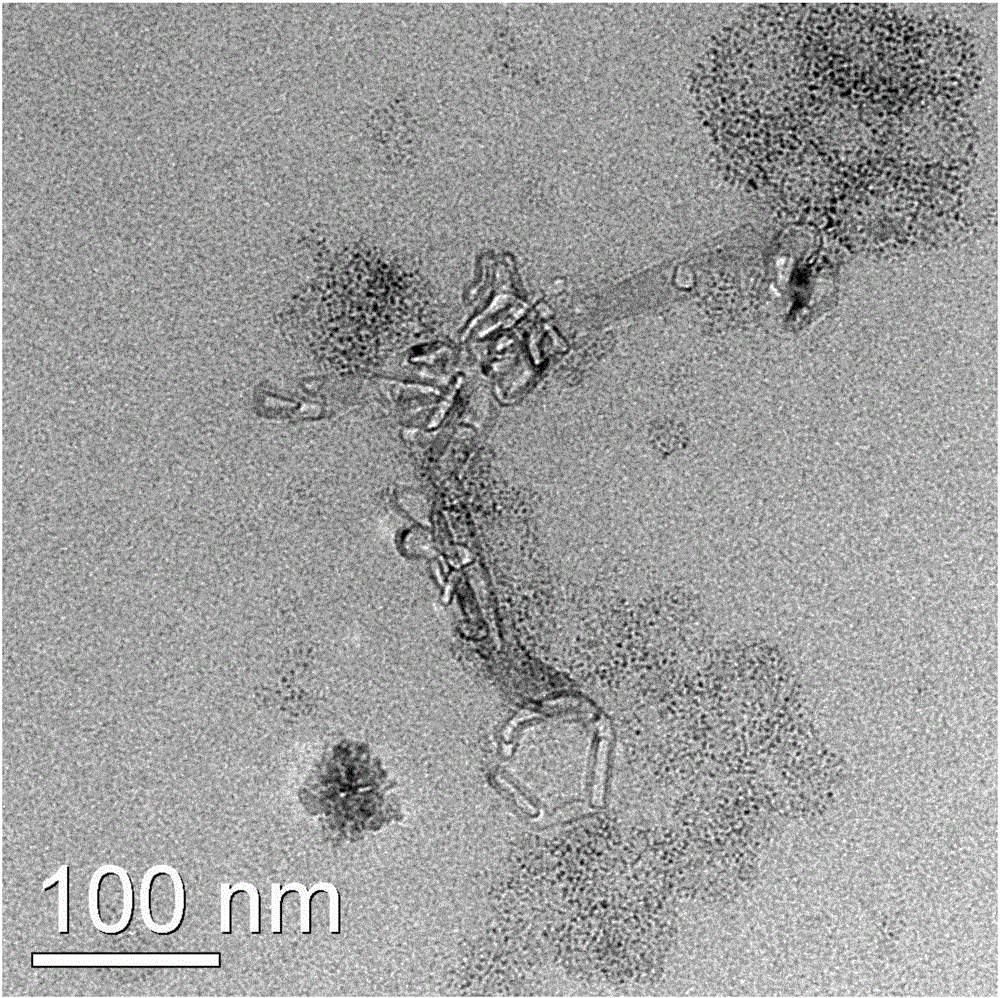

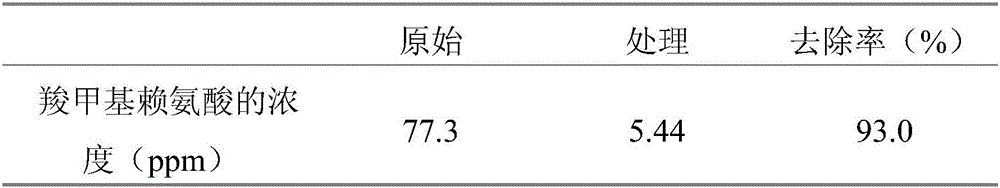

[0026] Mix 1.0mL of 1-allyl-3-methylimidazolium tetrafluoroborate, 20.0mL of ethanol, and 2.0mL of n-hexane, stir at room temperature for 1 hour, add 2.0g of carbon nanotubes, and heat to 85°C under nitrogen protection , reacted for 1 hour, cooled to room temperature, centrifuged, and the obtained precipitate was a carbon nanotube ionic liquid composite material. Its morphology and spatial dimensions were characterized by transmission electron microscopy, such as figure 1 shown. figure 1 The results show that the carbon nanotube ionic liquid composite is a nanostructure. In 100mL of brewed soy sauce, 1g of carbon nanotube ionic liquid composite material was added, and stirred and reacted at room temperature for 30 minutes. The concentration of carboxymethyllysine in brewed soy sauce and the removal rate (%) of carboxymethyllysine in brewed soy sauce before and after adding carbon nanotube ionic liquid composite materials are shown in Table 1.

[0027] Table 1

[0028]

...

Embodiment 2

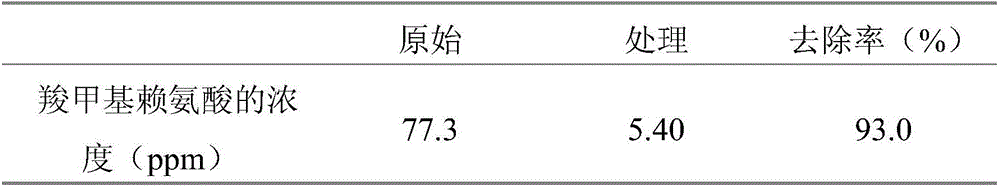

[0031] Mix 1.0mL of 1-allyl-3-butylimidazolium tetrafluoroborate, 20.0mL of n-propanol, and 2.0mL of n-hexane, stir at room temperature for 2 hours, add 5.0g of carbon nanotubes, and heat to After reacting for 3 hours at 70°C, cool to room temperature, and centrifuge to separate the obtained precipitate into a carbon nanotube ionic liquid composite material. Its morphology and spatial dimensions were characterized by transmission electron microscopy. The characterization diagram shows that the carbon nanotube ionic liquid composite material is a nanostructure. In 100mL of brewed soy sauce, add 2g of carbon nanotube ionic liquid composite material, and stir and react at room temperature for 20 minutes. Table 2 shows the concentration of carboxymethyllysine in brewed soy sauce and the removal rate (%) of carboxymethyllysine in brewed soy sauce before and after adding the carbon nanotube ionic liquid composite material.

[0032] Table 2

[0033]

[0034] The results in Tabl...

Embodiment 3

[0036] Mix 1.0mL of 1-allyl-3-methylimidazole bistrifluoromethanesulfonimide salt, 5.0mL of n-propanol, and 8.0mL of cyclohexane, stir at room temperature for 2.5 hours, add 3.0g of carbon nanotubes, and Under protection, heat to 78° C., react for 2 hours, cool to room temperature, and centrifuge, and the obtained precipitate is a carbon nanotube ionic liquid composite material. Its morphology and spatial dimensions were characterized by transmission electron microscopy. The characterization diagram shows that the carbon nanotube ionic liquid composite material is a nanostructure. In 100mL of brewed soy sauce, add 3g of carbon nanotube ionic liquid composite material, and stir and react at room temperature for 10 minutes. The concentration of carboxymethyllysine in brewed soy sauce and the removal rate (%) of carboxymethyllysine in brewed soy sauce before and after adding carbon nanotube ionic liquid composite materials are shown in Table 3.

[0037] table 3

[0038]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com