Quick-dissolving type seawater-based high-temperature fracturing fluid

A fracturing fluid and instant technology, applied in the field of fracturing fluids, can solve the problems of increased fracturing fluid treatment costs, discounted construction effects, and inability to be prepared and used immediately, achieving fast dissolving speed, complete gel breaking, and beneficial effects. seam effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

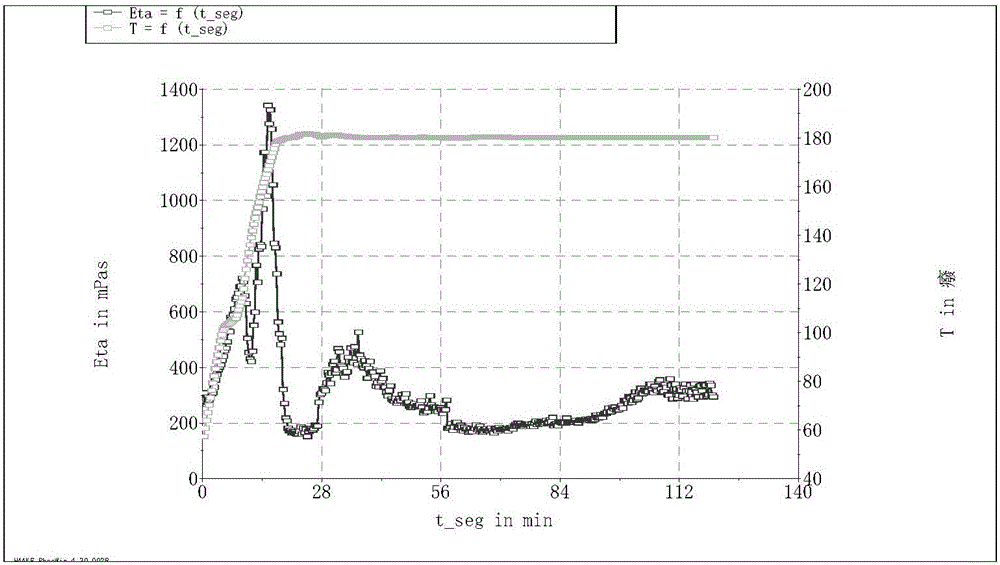

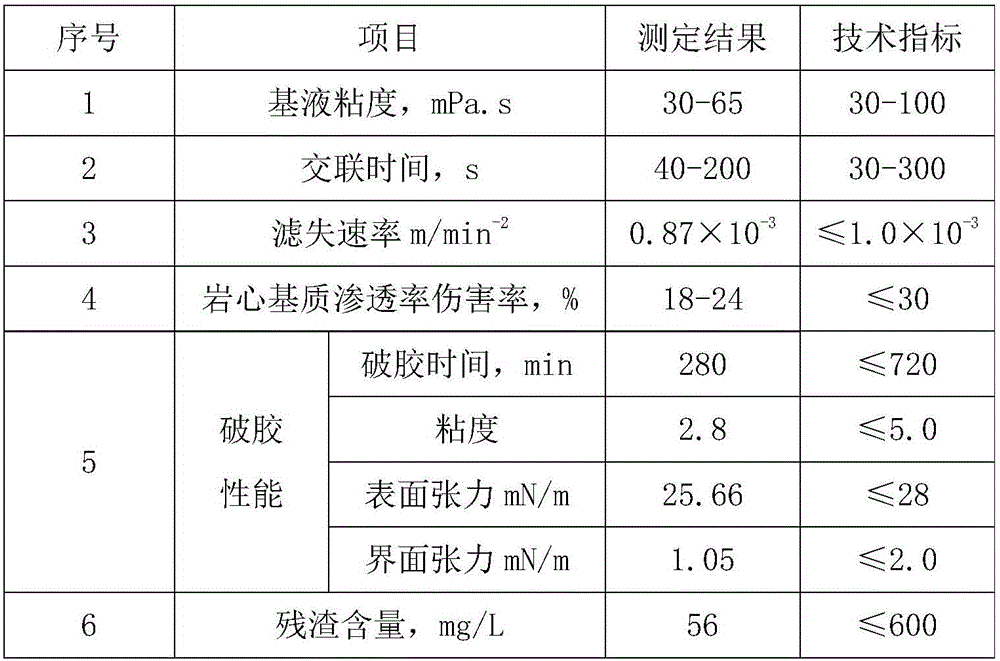

Image

Examples

Embodiment 1

[0022] Preparation of emulsion thickener

[0023] Prepare acrylamide, acrylic acid, 2-acrylamide-2-methylpropanesulfonate, and vinylpyrrolidone into a 60% aqueous solution with a mass ratio of 35:8:20:5, and adjust the system The pH is 5.5. In addition, take a certain amount of Siban-80 and Tween-20 of the same quality and add them to the oil phase cyclohexane. The emulsifier accounts for 10% of the mass fraction of the oil phase. After stirring, dispersing and dissolving, slowly mix the four Add the aqueous monomer solution into the oil phase, the oil-water ratio is 1.2:1, stir emulsification vigorously while adding, fill with nitrogen for 40min after the emulsification is completed, and add the redox initiation system (ammonium persulfate: sodium bisulfite = 1:2) , control the temperature at 35° C., and react for 8 hours to obtain an inverse emulsion with a final polymer content of 27%.

[0024] Pour 954 parts of seawater into the Warning mixer, start stirring, adjust the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com