Undesirable odor removing type laundry condensate bead and preparation method thereof

A technology of laundry condensation and odor, applied in the field of detergent, can solve the problems of waste, intolerance to hard water, unfavorable environmental protection, etc., and achieve the effect of reducing the amount of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

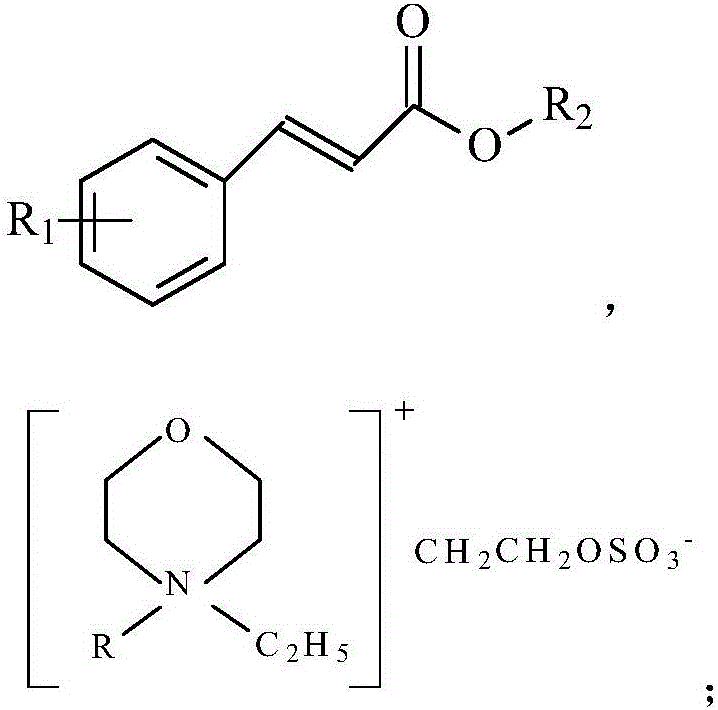

Method used

Image

Examples

Embodiment 1

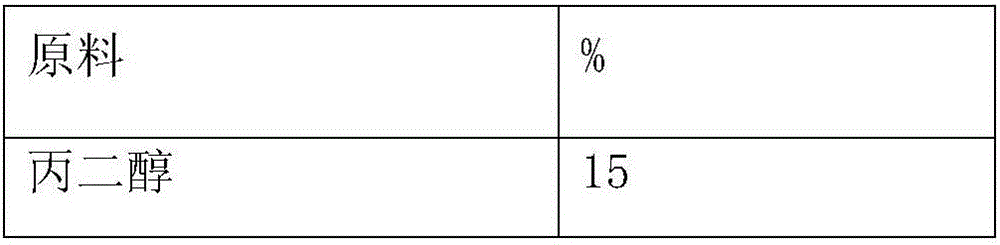

[0062] A kind of odor-removing laundry beads, which is composed of a water-soluble film and a cleaning solution in it, and the cleaning solution is prepared from the following components in terms of mass percentage:

[0063]

[0064]

[0065] The above-mentioned method for washing beads, the method comprises the following steps:

[0066] 1) Add raw materials in order of propylene glycol, sorbitol, glycerin, dodecylbenzenesulfonic acid, monoethanolamine, nonionic surfactant, coconut oleic acid, maleic acid / acrylic acid copolymer, and chelating agent, and the temperature is lower than 50 At ℃, add ethanol, odor remover, deionized water, essence, preservative, disgusting agent and enzyme to mix;

[0067] 2) After the liquid is qualified, it is packed with water-soluble film. The packaging method can be water-sealed or heat-sealed. Water-soluble film optional materials: polyvinyl alcohol, polyvinyl acetal, polyvinyl pyrrolidone, polyacrylic acid, maleic acid / acrylic acid c...

Embodiment 2

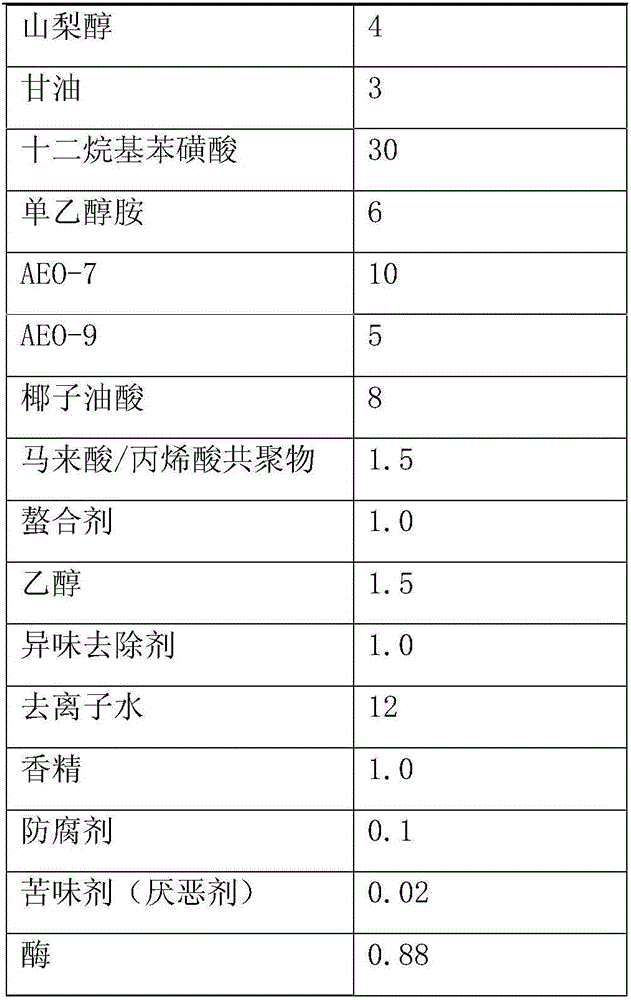

[0070] A kind of odor-removing laundry beads, which is composed of a water-soluble film and a cleaning solution in it, and the cleaning solution is prepared from the following components in terms of mass percentage:

[0071] raw material % Propylene Glycol 19 Sorbitol 3 glycerin 4 dodecylbenzenesulfonic acid 25 Monoethanolamine 4 AEO-9 5 AEO-3 10 coconut oil 10 Maleic acid / acrylic acid copolymer 1.0 Chelating agent 1.5 ethanol 2.0 odor remover 0.5 Deionized water 13 essence 1.0 preservative 0.1 bittering agent (aversion agent) 0.02 enzyme 0.88

[0072] The above-mentioned method for washing beads, the method comprises the following steps:

[0073] 1) Add raw materials in order of propylene glycol, sorbitol, glycerin, dodecylbenzenesulfonic acid, monoethanolamine, nonionic surfactant, coconut oleic acid, maleic acid / acrylic acid copolymer, and chelating agent, and ...

Embodiment 3

[0076] A kind of odor-removing laundry beads, which is composed of a water-soluble film and a cleaning solution in it, and the cleaning solution is prepared from the following components in terms of mass percentage:

[0077] raw material % Propylene Glycol 12.5 Sorbitol 5 glycerin 4 dodecylbenzenesulfonic acid 35 Monoethanolamine 6 AEO-9 10 coconut oil 9 Maleic acid / acrylic acid copolymer 1.0 Chelating agent 1.0 ethanol 1.0 odor remover 1.5 Deionized water 12 essence 1.0 preservative 0.1 bittering agent (aversion agent) 0.02 enzyme 0.88

[0078] The above-mentioned method for washing beads, the method comprises the following steps:

[0079] 1) Add raw materials in order of propylene glycol, sorbitol, glycerin, dodecylbenzenesulfonic acid, monoethanolamine, nonionic surfactant, coconut oleic acid, maleic acid / acrylic acid copolymer, and chelating agent, and the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com