Cross-color-proof type laundry condensate bead and preparation method thereof

A technology for laundry beads and anti-staining, which is applied in the field of detergents, can solve the problems of fading, waste, and detergency of clothes, and achieves the effect of stable coexistence and reduced packaging consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

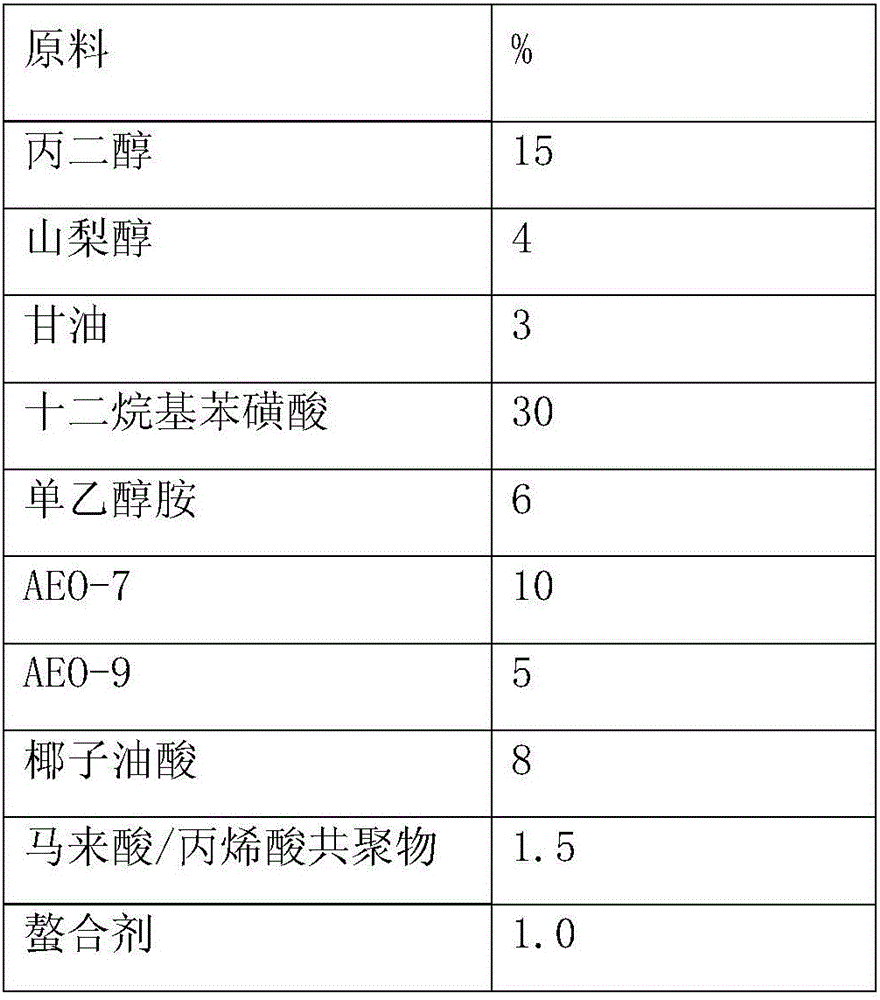

[0060] An anti-cross-color laundry condensation bead is composed of a water-soluble film and a cleaning solution in it. The cleaning solution is prepared from the following components in terms of mass percentage:

[0061]

[0062]

[0063] The above-mentioned method for washing beads, the method comprises the following steps:

[0064] 1) Add raw materials in order of propylene glycol, sorbitol, glycerin, dodecylbenzenesulfonic acid, monoethanolamine, nonionic surfactant, coconut oleic acid, maleic acid / acrylic acid copolymer, and chelating agent, and the temperature is lower than 50 At ℃, add ethanol, anti-crosslinking agent, deionized water, essence, preservative, aversion agent and enzyme to mix;

[0065] 2) After the liquid is qualified, it is packed with water-soluble film. The packaging method can be water-sealed or heat-sealed. Water-soluble film optional materials: polyvinyl alcohol, polyvinyl acetal, polyvinyl pyrrolidone, polyacrylic acid, maleic acid / acrylic ...

Embodiment 2

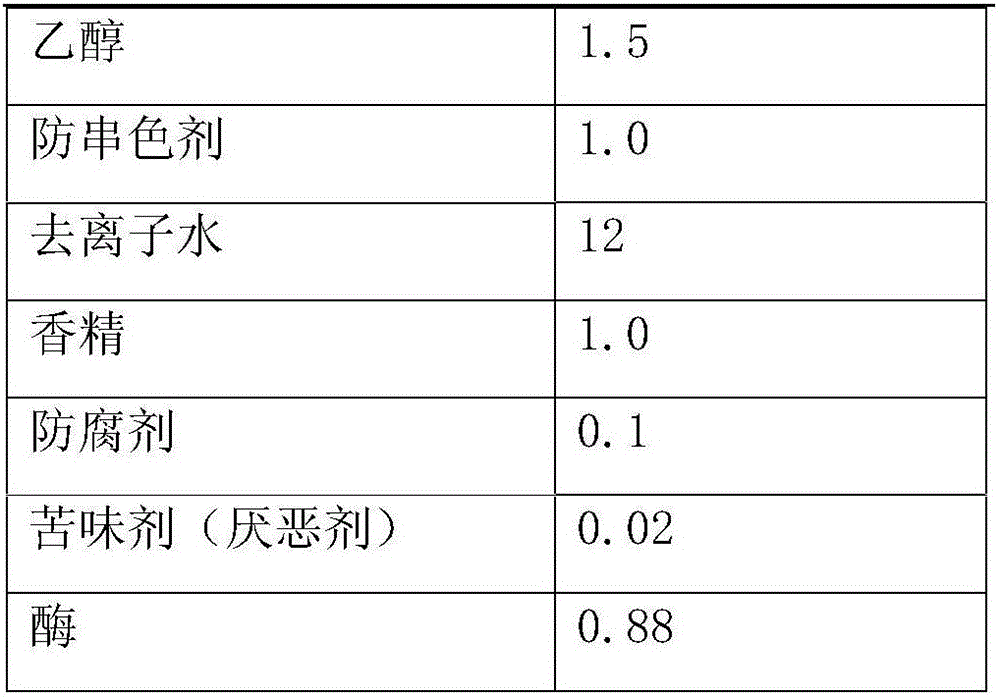

[0068] An anti-cross-color laundry condensation bead is composed of a water-soluble film and a cleaning solution in it. The cleaning solution is prepared from the following components in terms of mass percentage:

[0069]

[0070]

[0071] The above-mentioned method for washing beads, the method comprises the following steps:

[0072] 1) Add raw materials in order of propylene glycol, sorbitol, glycerin, dodecylbenzenesulfonic acid, monoethanolamine, nonionic surfactant, coconut oleic acid, maleic acid / acrylic acid copolymer, and chelating agent, and the temperature is lower than 50 At ℃, add ethanol, anti-crosslinking agent, deionized water, essence, preservative, aversion agent and enzyme to mix;

[0073] 2) After the liquid is qualified, it is packed with water-soluble film. The packaging method can be water-sealed or heat-sealed. Water-soluble film optional materials: polyvinyl alcohol, polyvinyl acetal, polyvinyl pyrrolidone, polyacrylic acid, maleic acid / acrylic ...

Embodiment 3

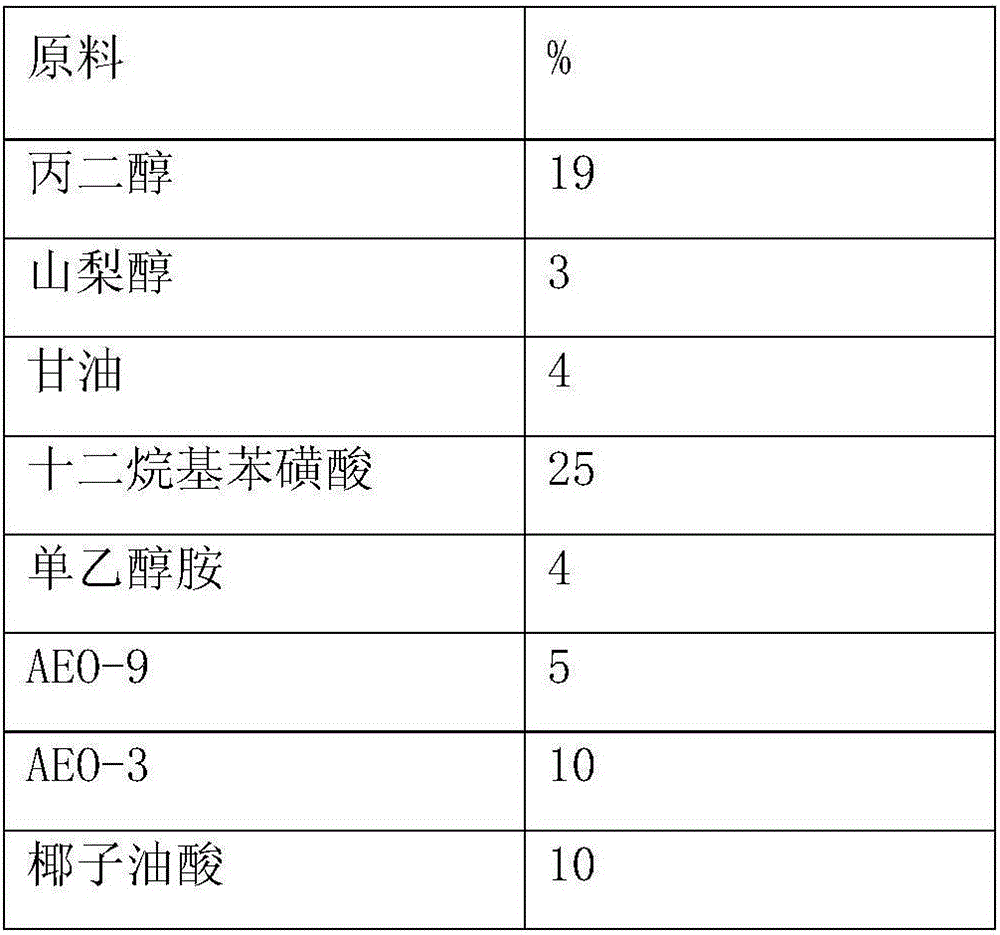

[0075] An anti-cross-color laundry condensation bead is composed of a water-soluble film and a cleaning solution in it. The cleaning solution is prepared from the following components in terms of mass percentage:

[0076]

[0077]

[0078] The above-mentioned method for washing beads, the method comprises the following steps:

[0079] 1) Add raw materials in order of propylene glycol, sorbitol, glycerin, dodecylbenzenesulfonic acid, monoethanolamine, nonionic surfactant, coconut oleic acid, maleic acid / acrylic acid copolymer, and chelating agent, and the temperature is lower than 50 At ℃, add ethanol, anti-crosslinking agent, deionized water, essence, preservative, aversion agent and enzyme to mix;

[0080] 2) After the liquid is qualified, it is packed with water-soluble film. The packaging method can be water-sealed or heat-sealed. Water-soluble film optional materials: polyvinyl alcohol, polyvinyl acetal, polyvinyl pyrrolidone, polyacrylic acid, maleic acid / acrylic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com