Rooting agent containing microcrystalline cellulose and preparation method thereof

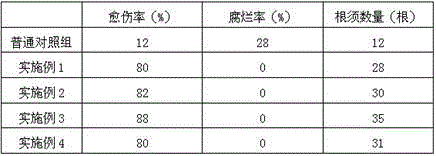

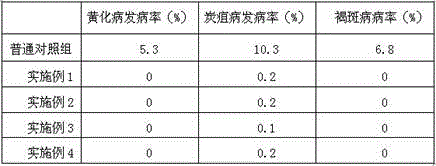

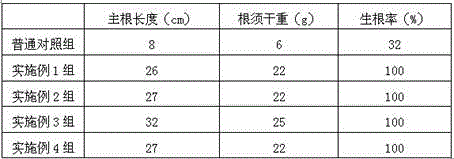

A technology of microcrystalline cellulose and rooting agent, applied in botany equipment and methods, biocide, biocide, etc., can solve the problem of low rooting rate of osmanthus cuttings, low callus rate of osmanthus cuttings, high incidence of osmanthus cuttings, etc. problem, to achieve the effects of enhanced disease prevention, improved immunity, and improved rooting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A rooting agent containing microcrystalline cellulose, in parts by weight, comprises the following raw materials:

[0037] 6 parts of sodium pyrophosphate, 1.5 parts of urine formaldehyde powder, 2 parts of Artemisia annua extract, 0.9 part of honeysuckle extract, 0.5 part of wormwood extract, 13 parts of polylactic acid resin, 7 parts of potassium superoxide, 1.5 parts of black iron oxide, 4 parts of microcrystalline cellulose, 28 parts of creeper extract, 1.9 parts of psyllium seed gum.

[0038] The Artemisia annua extract has an artemisinin content of 8-10% and an artemisinic acid content of 1.5-1.7%;

[0039] The honeysuckle extract has a chlorogenic acid content of 25-30%;

[0040] The wormwood extract has a total flavonoid content of 13-16%;

[0041] The microcrystalline cellulose has a degree of polymerization of 260-280 and a pH value of 6.2-6.5;

[0042] The ivy extract: cut off the big leaves of the ivy and leave the small leaves; cut the remai...

Embodiment 2

[0044] Embodiment 2 A kind of rooting agent containing microcrystalline cellulose, adopts the method described in embodiment 1, only changes the proportioning of raw material, changes into:

[0045] 7 parts of sodium pyrophosphate, 1.7 parts of urine formaldehyde powder, 3 parts of Artemisia annua extract, 1.0 part of honeysuckle extract, 0.8 part of wormwood extract, 15 parts of polylactic acid resin, 8 parts of potassium superoxide, 1.6 parts of black iron oxide, 5 parts of microcrystalline cellulose, 30 parts of creeper extract, 2 parts of psyllium seed gum.

Embodiment 3

[0046] Embodiment 3 A kind of rooting agent containing microcrystalline cellulose, adopts the method described in embodiment 1, only changes the proportioning of raw material, changes into:

[0047] 8 parts of sodium pyrophosphate, 1.9 parts of urine formaldehyde powder, 4 parts of Artemisia annua extract, 1.2 parts of honeysuckle extract, 0.9 parts of wormwood extract, 16 parts of polylactic acid resin, 9 parts of potassium superoxide, 1.7 parts of black iron oxide, 6 parts of microcrystalline cellulose, 31 parts of creeper extract, 2.2 parts of psyllium seed gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com