A method for resource utilization of kerosene co-refining residue modification

A technology for kerosene co-refining residue and resource utilization, which is applied in the gasification process, petroleum industry, powder suspension granulation and other directions, can solve the problems of too coarse particle size, ineffective dispersion, adhesion on the surface of the grinding rod, etc. Improve grindability, increase dispersibility, reduce adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

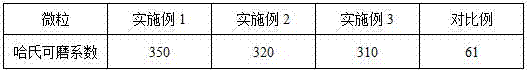

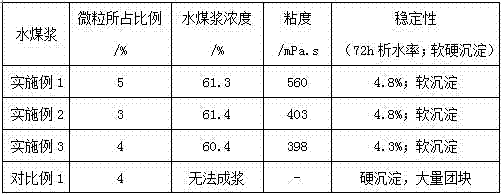

Embodiment 1

[0027] A method for resource utilization of kerosene co-refining residue modification is as follows:

[0028] (1) Injection micronization: The kerosene co-refining residue is cooled to 120°C after heat exchange to maintain its fluidity. After being mixed with air by a high-pressure pump, it passes through a nickel-based alloy trumpet-shaped nozzle with an aperture of 0.1-1mm. The upper part of the nozzle is equipped with an air flow channel and a residue flow channel. The two channels converge at the upper part of the nozzle, and are sprayed at high speed by the air flow to disperse the residue into particles with a particle size of 0.1~1mm.

[0029] (2) Surface impregnation modification: the particles are injected into the modified dipping pool at the lower part of the nozzle. The pool contains an aqueous solution containing a polymer surface modifier. The concentration of the aqueous solution is 2%, and the raw material composition of the polymer surface modifier is : 1% mal...

Embodiment 2

[0033] A method for resource utilization of kerosene co-refining residue modification is as follows:

[0034] (1) Injection micronization: The kerosene co-refining residue is cooled to 140°C after heat exchange to maintain its fluidity. After being mixed with air by a high-pressure pump, it passes through a nickel-based alloy trumpet-shaped nozzle with an aperture of 1-10mm. The upper part of the nozzle has an air flow channel and a residue flow channel. The two channels converge at the upper part of the nozzle, and are sprayed at high speed by the air flow to disperse the residue into particles with a particle size of 1~10mm.

[0035] (2) Surface impregnation modification: the particles are injected into the modified dipping pool at the lower part of the nozzle. The pool contains an aqueous solution containing a polymer surface modifier. The concentration of the aqueous solution is 1%, and the raw material composition of the polymer surface modifier is : 5% maleic acid, 43%C ...

Embodiment 3

[0039] A method for resource utilization of kerosene co-refining residue modification is as follows:

[0040] (1) Injection micronization: The kerosene co-refining residue is cooled to 150°C after heat exchange to maintain its fluidity. After being mixed with air by a high-pressure pump, it passes through a nickel-based alloy trumpet-shaped nozzle with an aperture of 0.1-2mm. The upper part of the nozzle has an air flow channel and a residue flow channel. The two channels converge at the upper part of the nozzle, and are sprayed by the air at high speed to disperse the residue into particles with a particle size of 0.1~2mm.

[0041] (2) Surface impregnation modification: the particles are injected into the modified dipping pool at the lower part of the nozzle. The pool contains an aqueous solution containing a polymer surface modifier. The concentration of the aqueous solution is 3%, and the raw material composition of the polymer surface modifier is : 2% maleic acid, 10% C 10~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com