Lithium ion battery material preparation method

A lithium-ion battery and carbon material technology, applied in the field of electrochemistry, can solve problems such as large polarization, low conductivity, and increased battery internal resistance and mass transfer resistance, and achieve the effect of reducing processing difficulty and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Weigh titanium dioxide, lithium carbonate, respectively 20 kg and 7.96 kg, add 100 kg of pure water, mix and stir, carry out wet ball milling, ball milling time is 1 hour, then spray dry, under air atmosphere, the material obtained by spray drying Carry out sintering, the sintering temperature is 850° C., and the sintering time is 4 hours, and the semi-finished lithium titanate is prepared. Weigh semi-finished lithium titanate and carbon nanotubes, respectively 10 kg and 0.1 kg, and perform wet ball milling for 2 hours. Then spray dry, under nitrogen atmosphere, at 850 ℃ temperature, sinter for 6 hours, the tap density of preparation is 1.35g / cm 3 of lithium titanate.

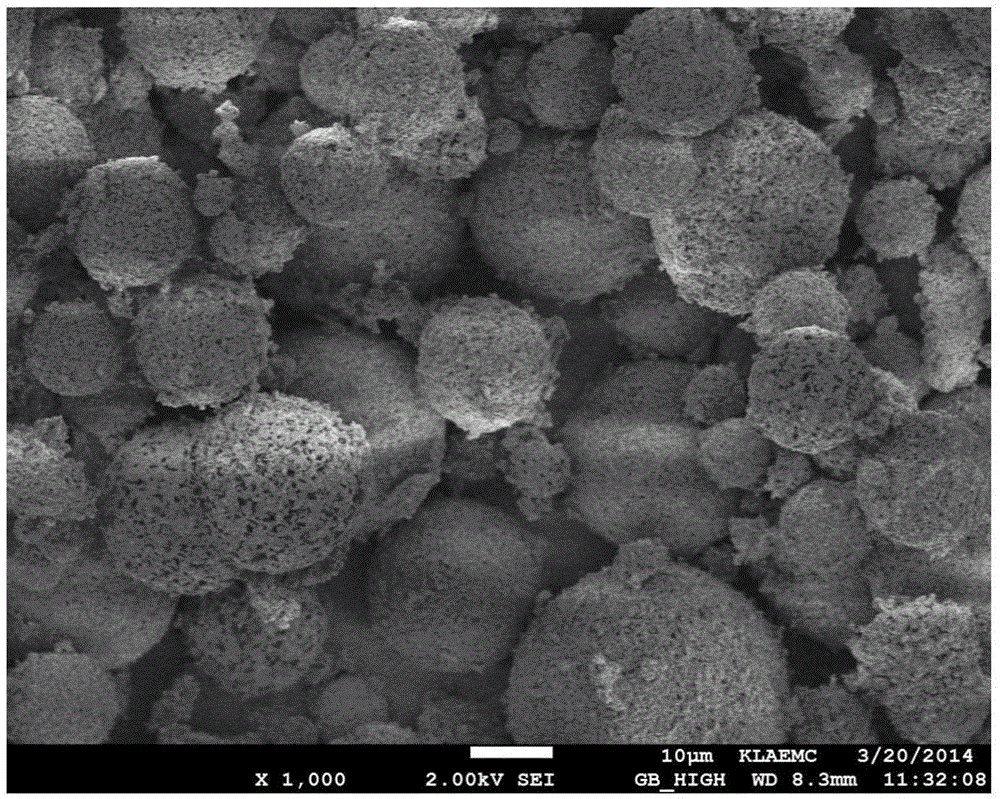

[0030] figure 1 It is the scanning electron micrograph of the lithium titanate prepared in the embodiment of the present invention 1, from figure 1 It can be seen that the spherical effect of lithium titanate is better, and the spherical shape is tighter, which can effectively improve the tap density....

example 2

[0032] Weigh titanium dioxide, lithium hydroxide, respectively 10 kg and 2.58 kg, add 45 kg of pure water, mix and stir, carry out wet ball milling, ball milling time is 1 hour, then spray dry, under air atmosphere, spray dry the obtained The material is sintered, the sintering temperature is 800° C., and the sintering time is 6 hours, and the semi-finished lithium titanate is prepared. Weigh semi-finished lithium titanate and carbon nanotubes, respectively 10 kg and 0.2 kg, and perform wet ball milling for 5 hours. Then it was spray-dried and sintered for 8 hours at 800°C under a nitrogen atmosphere to obtain a tap density of 1.34g / cm 3 of lithium titanate.

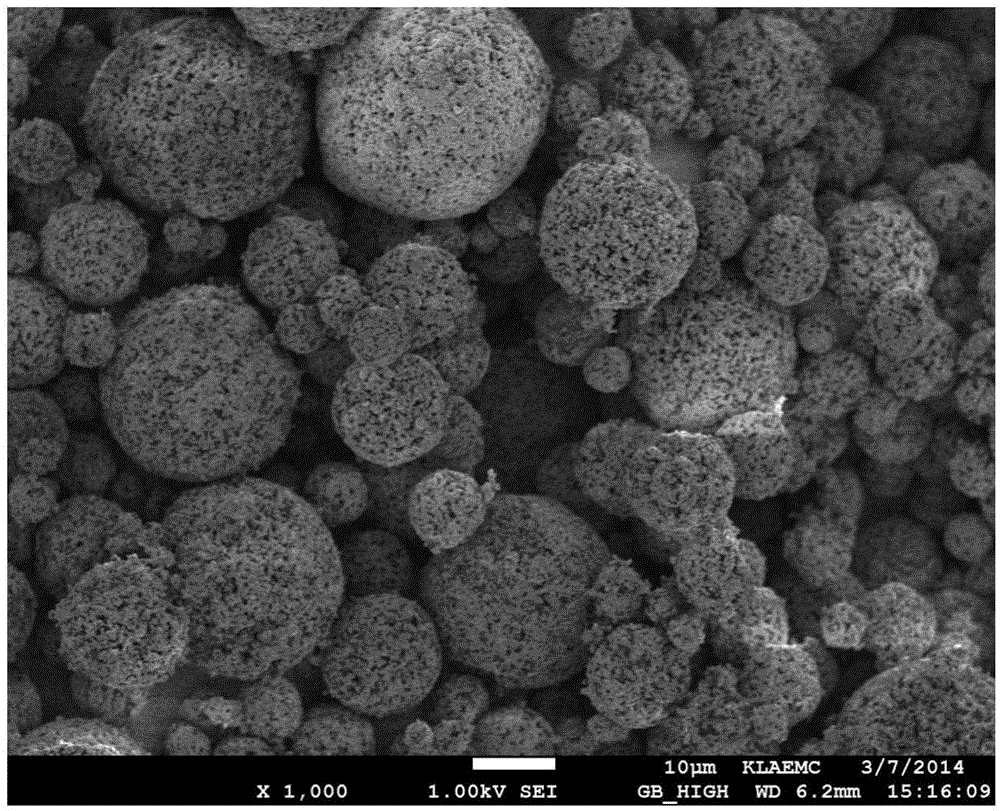

[0033] figure 2 It is the scanning electron micrograph of the lithium titanate prepared in the embodiment 2 of the present invention, from figure 2 It can be seen that lithium titanate has a good ball forming effect, the spherical shape is regular, and the tap density of the material is high.

example 3

[0035] Weigh titanium dioxide and lithium carbonate, respectively 20 kg and 7.96 kg, add 100 kg of pure water, mix and stir, carry out wet ball milling, ball milling time is 0.5 hour, then spray dry, under air atmosphere, the material obtained by spray drying Carry out sintering, the sintering temperature is 900° C., and the sintering time is 4 hours, and the semi-finished lithium titanate is prepared. Weigh semi-finished lithium titanate and conductive carbon black, respectively 15 kg and 0.1 kg, and perform wet ball milling for 5 hours. Then it was spray dried, and sintered for 8 hours at 800°C under a nitrogen atmosphere to obtain a tap density of 1.38g / cm 3 of lithium titanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com