Method for preparing nano calcium sulfate

A technology of nano calcium sulfate and crystal form control agent, which is applied in nanotechnology, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of difficult product handling and environmental pollution, and achieve the effect of growth inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

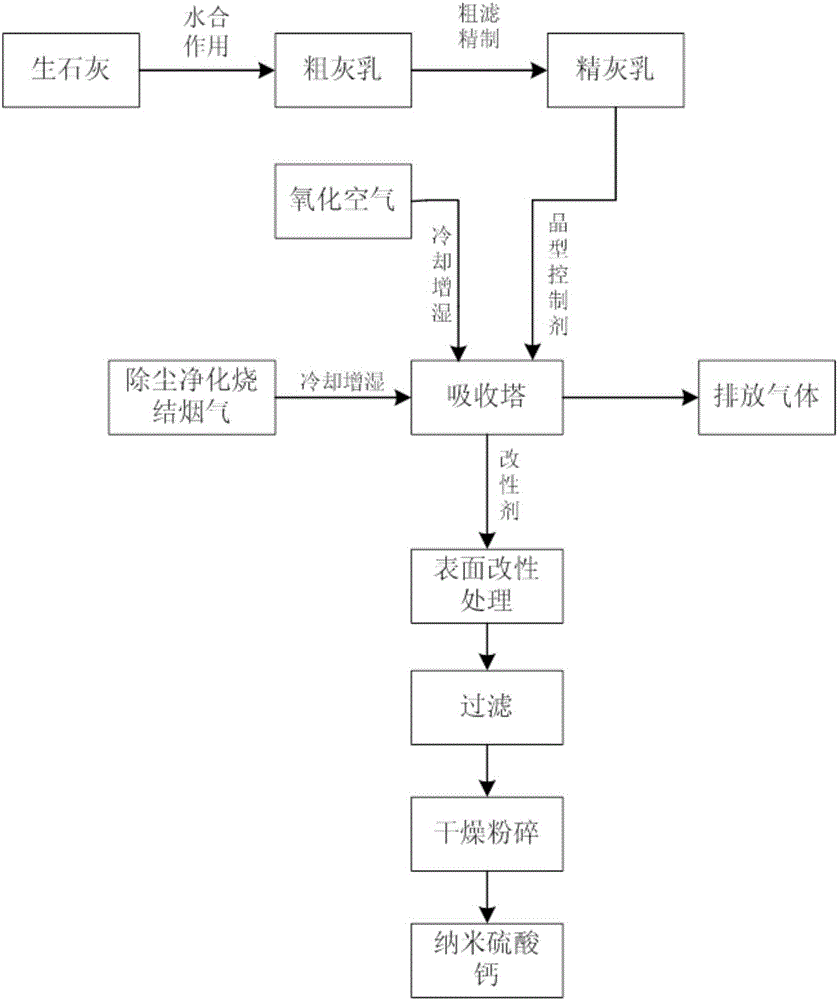

Image

Examples

Embodiment 1

[0049] The method of utilizing sintering flue gas of the present embodiment to prepare nanometer calcium sulfate comprises the steps:

[0050] 1) Pass the sintering flue gas after dedusting, purification and cold humidification into the cooling tower for cooling and humidification, and the SO in the sintering flue gas after cooling and humidification 2 The concentration is 1800mg / m 3 ;

[0051] 2) Add water to the quicklime for digestion reaction to generate coarse lime milk, coarsely filter and refine the obtained coarse lime milk to obtain refined lime milk, and the obtained refined lime milk has a density of 1200kg / m 3 , adding 3% sulfuric acid solution with a mass fraction of 98% in the refined gray milk as a crystal form control agent, and emulsifying with a high-shear emulsifier to make the reaction slurry fully refined and uniform;

[0052] 3) adding a strengthening agent with a mass fraction of 2% to the emulsified gray milk, in parts by mass, the strengthening agent...

Embodiment 2

[0058] The method of utilizing sintering flue gas of the present embodiment to prepare nanometer calcium sulfate comprises the steps:

[0059] 1) Pass the sintering flue gas after dedusting, purification and cold humidification into the cooling tower for cooling and humidification, and the SO in the sintering flue gas after cooling and humidification 2 The concentration is 1500mg / m 3 ;

[0060] 2) Add water to quicklime for digestion reaction to generate coarse lime milk, coarsely filter and refine the obtained coarse lime milk to obtain refined lime milk, the density of the obtained refined lime milk is 1300kg / m 3 , adding 5% sulfuric acid solution with a mass fraction of 98% in the refined gray milk as a crystal form control agent, and emulsifying with a high-shear emulsifier to make the reaction slurry fully refined and uniform;

[0061] 3) adding a strengthening agent with a mass fraction of 4% to the emulsified lime milk, in parts by mass, the strengthening agent is mad...

Embodiment 3

[0067] The method of utilizing sintering flue gas of the present embodiment to prepare nanometer calcium sulfate comprises the steps:

[0068] 1) Pass the sintering flue gas after dedusting, purification and cold humidification into the cooling tower for cooling and humidification, and the SO in the sintering flue gas after cooling and humidification 2 The concentration is 2000mg / m 3 ;

[0069] 2) Add water to the quicklime for digestion reaction to generate coarse lime milk, coarsely filter and refine the obtained coarse lime milk to obtain refined lime milk, and the obtained refined lime milk has a density of 1250kg / m 3 , adding a mass fraction of 2% sulfuric acid solution with a mass fraction of 98% in the refined gray milk as a crystal form control agent, and emulsifying with a high-shear emulsifier to make the reaction slurry fully refined and uniform;

[0070] 3) adding a strengthening agent with a mass fraction of 5% to the emulsified lime milk, in parts by mass, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com