Electric-plated PC/ABS alloy and preparation method thereof

A technology of alloy and formulation, applied in the field of PC/ABS alloy and its preparation, can solve the problems of poor compatibility, low tensile strength, low impact strength, etc., and achieve improved gloss, improved compatibility, and product qualification rate Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

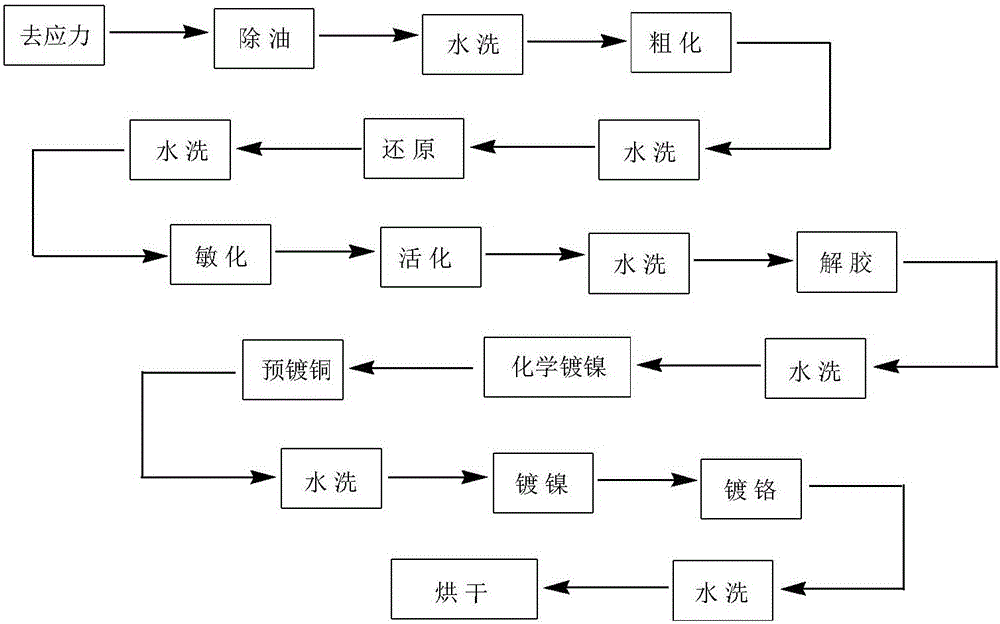

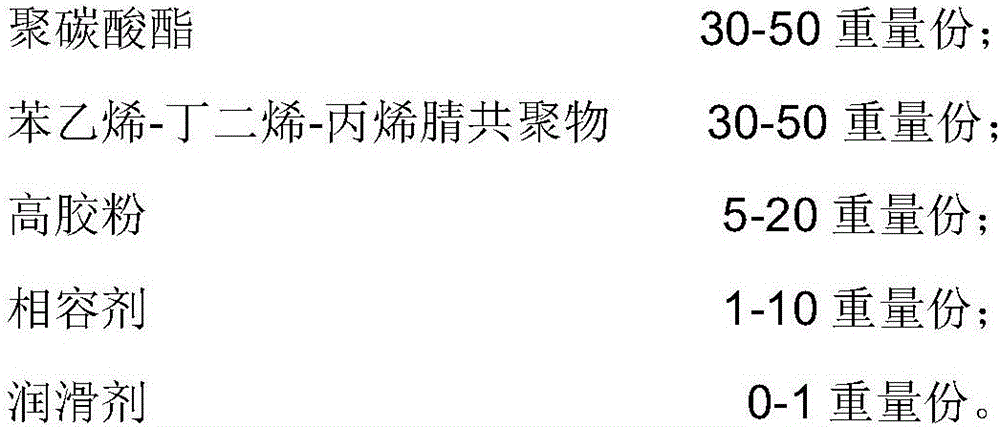

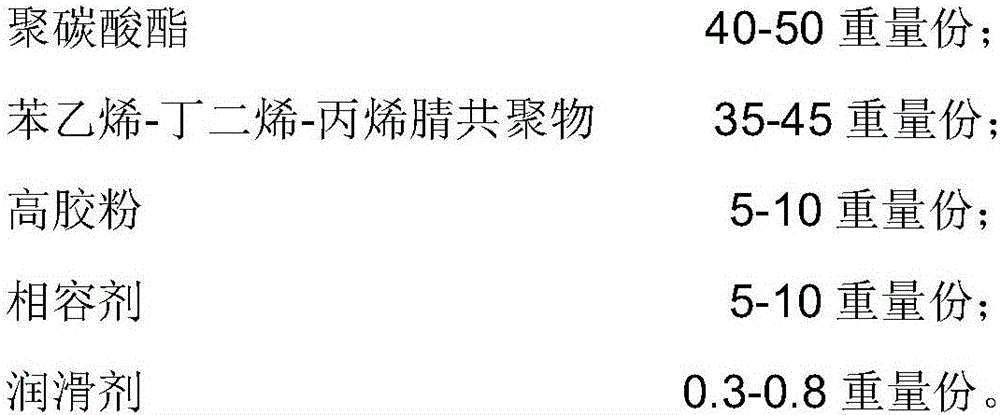

Method used

Image

Examples

Embodiment 1

[0038] Put 50 parts by weight of PC, 35 parts by weight of ABS, 8 parts by weight of high rubber powder, 6 parts by weight of compatibilizer, 0.6 parts by weight of antioxidant and 0.4 parts by weight of lubricant in a medium-speed mixing agitator, and stir and mix for 10~ After 30 minutes, the mixed material was obtained.

[0039] Put the obtained mixed material into the twin-screw extruder, control the screw speed to 200rpm, and control the temperature ranges of the 10 temperature control zones of the twin-screw extruder as follows, from the feed section to the machine head: 200°C, 200°C ℃, 210°C, 210°C, 220°C, 220°C, 220°C, 220°C, 250°C, die head 260°C, after extrusion, the material is water-cooled, pelletized, and then packaged. The pellets were dried to constant weight in a forced air oven, and then test specimens were prepared by injection molding machine.

[0040] The twin-screw extruder includes two vacuum places, one is located at the end of the conveying section and...

Embodiment 2

[0042] Put 45 parts by weight of PC, 40 parts by weight of ABS, 8 parts by weight of high-grade rubber powder, 6 parts by weight of compatibilizer, 0.6 parts by weight of antioxidant and 0.4 parts by weight of lubricant in a medium-speed mixing agitator, and stir and mix for 10~ After 30 minutes, the mixed material was obtained.

[0043] Put the obtained mixed material into the twin-screw extruder, control the screw speed to 200rpm, and control the temperature ranges of the 10 temperature control zones of the twin-screw extruder as follows, from the feed section to the machine head: 200°C, 200°C ℃, 210°C, 210°C, 220°C, 220°C, 220°C, 220°C, 250°C, die head 260°C, after extrusion, the material is water-cooled, pelletized, and then packaged. The pellets were dried to constant weight in a forced air oven, and then test specimens were prepared by injection molding machine.

[0044] The twin-screw extruder includes two vacuum places, one is located at the end of the conveying secti...

Embodiment 3

[0046] Put 50 parts by weight of PC, 35 parts by weight of ABS, 6 parts by weight of high rubber powder, 8 parts by weight of compatibilizer, 0.6 parts by weight of antioxidant and 0.4 parts by weight of lubricant in a medium-speed mixing agitator, and stir and mix for 10~ After 30 minutes, the mixed material was obtained.

[0047] Put the obtained mixed material into the twin-screw extruder, control the screw speed to 200rpm, and control the temperature ranges of the 10 temperature control zones of the twin-screw extruder as follows, from the feed section to the machine head: 200°C, 200°C ℃, 210°C, 210°C, 220°C, 220°C, 220°C, 220°C, 250°C, die head 260°C, after extrusion, the material is water-cooled, pelletized, and then packaged. The pellets were dried to constant weight in a forced air oven, and then test specimens were prepared by injection molding machine.

[0048] The twin-screw extruder includes two vacuum locations, one is located at the end of the conveying section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com