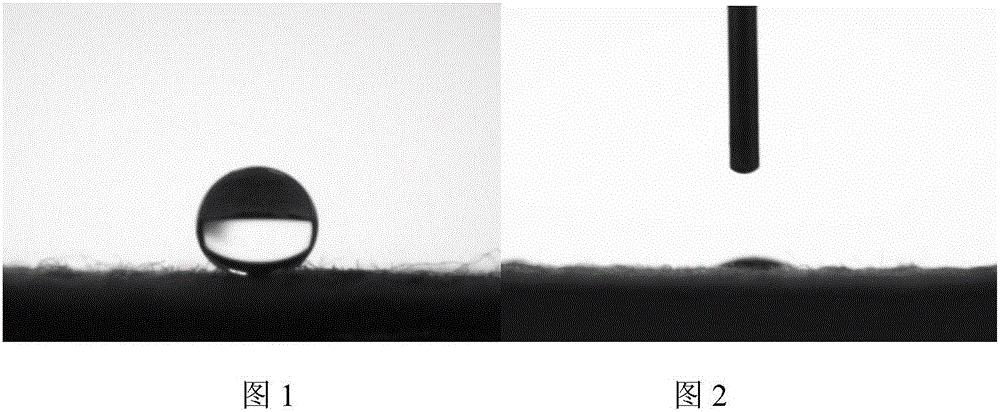

Method for preparing high-strength antibacterial oil-water separation type material through cold plasma pretreatment

A technology of cold plasma and oil-water separation, which is applied in fiber treatment, physical treatment, biochemical fiber treatment, etc. It can solve the problems of insufficient research and achieve the effects of uniform distribution, large application prospects, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Embodiment: The cold plasma pretreatment method of this embodiment prepares high-strength antibacterial oil-water separation type material, comprising the following steps:

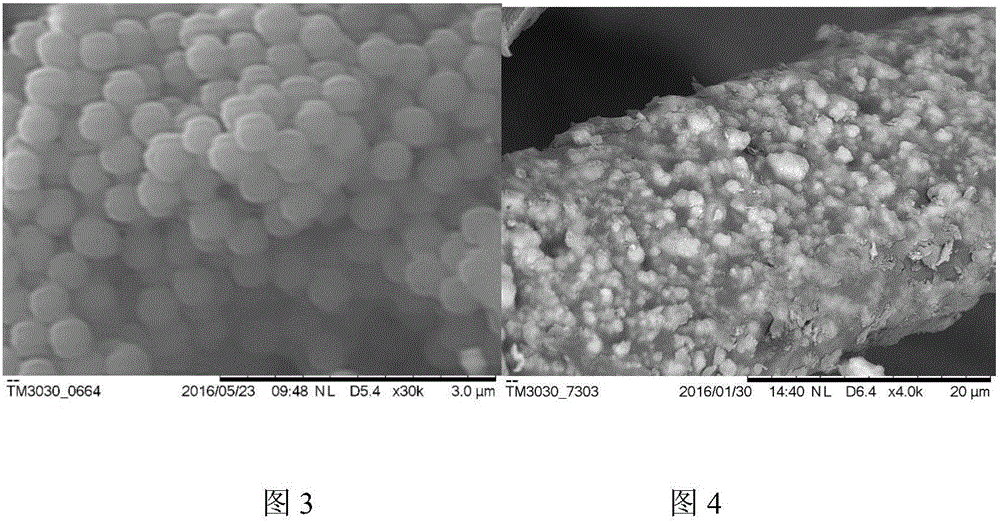

[0033] 1. Preparation of silver-loaded silica:

[0034] The silicon dioxide particles with a particle diameter of 200nm and a mass fraction of 0.4%, a silver nitrate aqueous solution with a concentration of 0.3g / mL as a volume fraction of 10%, and an aqueous solution of sodium citrate with a concentration of 50g / mL as a volume fraction of 1% were successively added to ethanol: In a solvent with a water volume ratio of 1:1, stir magnetically at room temperature for 2 hours, wash with centrifuge and alcohol, and then calcine after vacuum drying (placed in a muffle furnace, temperature programmed at a rate of 10°C per minute, under nitrogen protection at 500 ℃ calcined for 3 hours), cooled, and continued to grind for 0.5 hours;

[0035] 2. Cold plasma pretreatment of substrate:

[0036] The substrate...

specific Embodiment approach 2

[0042] Specific embodiment two: the difference between this embodiment and specific embodiment one is step four, fix the base material, slowly move the spray gun, keep the distance between it and the spray gun at 20cm, and the spraying pressure is 100kPa: first spray the second treatment liquid on the base The surface of the substrate, 3 times with an interval of 10 seconds, and then placed at room temperature for 2 hours; then spray the third treatment solution on the surface of the substrate, 3 times with an interval of 10 seconds, and dry at room temperature.

specific Embodiment approach 3

[0043] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 2, the gas introduced is argon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com