Low-resistance adsorbing material based on resin microspheres and application of low-resistance adsorbing material

A technology of resin microspheres and microspheres, which is applied in the direction of preparation of microspheres, adsorption of water/sewage treatment, materials of anion exchangers, etc., can solve problems such as difficulty in exerting effect, high bed resistance, impossibility of application, etc., and achieve exchange capacity and the effect of no decrease in accuracy and small internal diffusion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

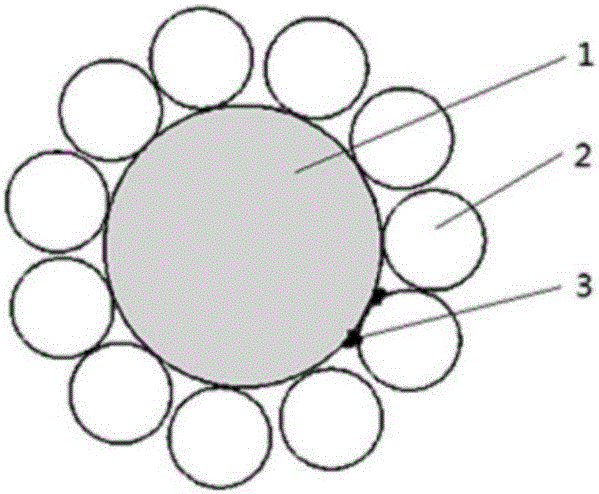

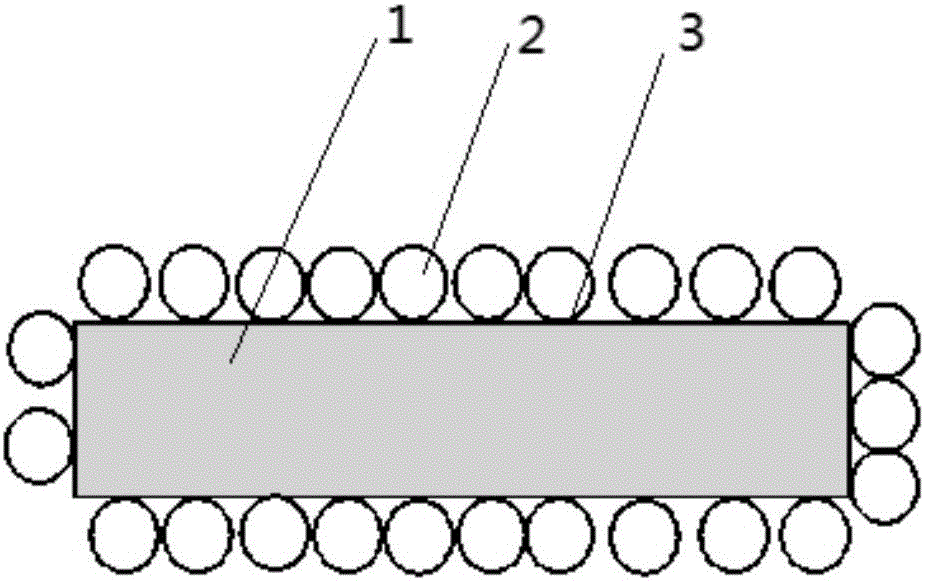

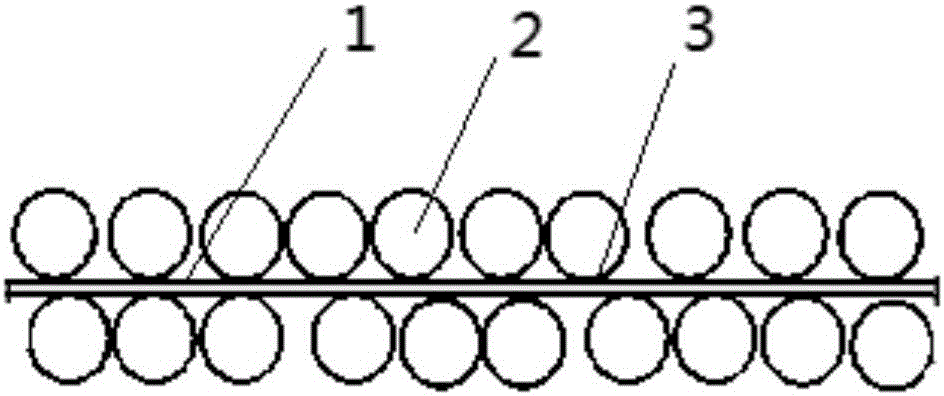

[0031] Dilute glue A of epoxy AB glue to the appropriate viscosity with thinner, add the required amount of glue B, mix quickly, take 120ml and spread it on a 300x400mm horizontal plate, with a depth of about 1mm, and 400g of polypropylene plastic balls with a diameter of 3mm. Apply glue on the surface of the glue plate three times. Immediately after the glue is applied, the plastic balls are moved one by one into the plate with a sufficient amount of macroporous strong acid cation exchange resin microspheres (type 732) with an average diameter of 1.0 mm. Shake the plate to make the surface of the plastic balls The resin microspheres were covered or nearly full, removed, and cured at room temperature in a fume hood to obtain the macroporous strongly acidic cation exchange resin low-resistance adsorbent of this embodiment. Take 20ml of the adsorbent and spread it in a horizontal plate, and judge that the adhesion rate of the resin microspheres on the surface of the plastic balls...

Embodiment 2

[0035] Dilute the silicone adhesive to an appropriate viscosity, take 240ml and spread it on a 300x400mm horizontal plate, with a depth of about 2mm, and 1000ml of polypropylene plastic balls with a diameter of 3mm, and apply glue on the surface of the glue plate in three times. Move it into a plate with a sufficient amount of hydrophobic adsorption resin microspheres A with an average diameter of 1.0mm (average pore diameter 1.8nm, volume of pores with a diameter greater than 1.5nm 0.25ml / g, contact angle with water 110°), shake the plate, The surface of the plastic ball is covered or nearly covered with resin microspheres, removed, and cured at room temperature in a fume hood to prepare the hydrophobic adsorption resin low-resistance adsorption material of this embodiment. Take 20ml of the adsorbent and spread it in a horizontal plate, and judge that the adhesion rate of the resin microspheres on the surface of the plastic balls is about 80%.

[0036] Judging from the prepar...

Embodiment 3

[0039] Dilute the silicone adhesive to an appropriate viscosity, take 240ml and spread it on a 300x400mm horizontal plate, with a depth of about 2mm, and 1000ml of inert ceramic balls with a diameter of 3mm, apply glue on the surface of the glue plate in three times, and immediately move the ceramic balls into the glue plate one by one Put a sufficient amount of hydrophobic adsorption resin microspheres B with an average diameter of 1.0mm (the average pore diameter is 2.1nm, the volume of pores with a diameter greater than 1.8nm is 0.20ml / g, and the contact angle with water is 125°), shake the plate to make The surface of the ceramic balls is covered or nearly covered with resin microspheres, removed, and cured at room temperature in a fume hood to prepare the hydrophobic adsorption resin low-resistance adsorption material of this embodiment. Take 20ml of the adsorbent and spread it in a horizontal plate, and judge that the adhesion rate of the resin microspheres on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com