Method for producing polyaluminium sulfate from aluminum profile machining waste liquid

A technology for processing polyaluminum sulfate and aluminum profiles, which is applied in the field of clean production and resource reuse, can solve problems such as affecting the environment and clean production, and achieve the effects of overcoming the low effective concentration of products, protecting the environment and increasing economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

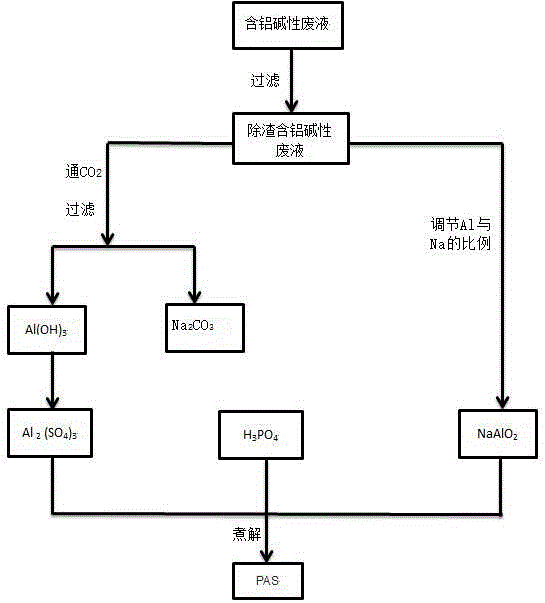

Image

Examples

Embodiment 1

[0030] The aluminum-containing alkaline waste liquid produced during the processing of aluminum profiles is used as the raw material, and the main component of the raw material is NaAlO 2 and NaOH, with a small amount of metal hydroxides in the form of precipitates. Polyaluminum sulfate was synthesized by the following method:

[0031] 1) Pass the aluminum-containing alkaline waste liquid through a 200-mesh sieve to remove solid impurities contained therein, and obtain the deslagging aluminum-containing alkaline waste liquid for future use.

[0032] 2) Take part of the deslagging aluminum-containing alkaline waste liquid obtained in step 1) and pass carbon dioxide into it, so that sodium metaaluminate is hydrolyzed and aluminum hydroxide precipitates, until no more precipitation occurs, press filter to separate, and obtain Solid Al(OH) 3 and Na 2 CO 3 solution, set aside.

[0033] 3) The solid Al(OH) obtained in step 2) 3 Dissolved in 40% H 2 SO 4 solution until solid ...

Embodiment 2

[0039] The aluminum-containing alkaline waste liquid produced during the processing of aluminum profiles is used as the raw material, and the main component of the raw material is NaAlO 2 and NaOH, with a small amount of metal hydroxides in the form of precipitates. Polyaluminum sulfate was synthesized by the following method:

[0040] 1) Pass the aluminum-containing alkaline waste liquid through a 800-mesh sieve to remove the solid impurities contained therein, and obtain the deslagging aluminum-containing alkaline waste liquid, which is set aside;

[0041] 2) Take part of the deslagging aluminum-containing alkaline waste liquid obtained in step 1) and pass carbon dioxide into it, so that sodium metaaluminate is hydrolyzed and aluminum hydroxide precipitates, until no more precipitation occurs, press filter to separate, and obtain Solid Al(OH) 3 and Na 2 CO 3 solution, spare;

[0042] 3) The solid Al(OH) obtained in step 2) 3 Dissolved in 20% H 2 SO 4 solution until s...

Embodiment 3

[0048] The aluminum-containing alkaline waste liquid produced during the processing of aluminum profiles is used as the raw material, and the main component of the raw material is NaAlO 2 and NaOH, with a small amount of metal hydroxides in the form of precipitates. Polyaluminum sulfate was synthesized by the following method:

[0049] 1) Pass the aluminum-containing alkaline waste liquid through a 600-mesh sieve to remove the solid impurities contained therein, and obtain the deslagging aluminum-containing alkaline waste liquid for later use;

[0050] 2) Take part of the deslagging aluminum-containing alkaline waste liquid obtained in step 1) and pass carbon dioxide into it, so that sodium metaaluminate is hydrolyzed and aluminum hydroxide precipitates, until no more precipitation occurs, press filter to separate, and obtain Solid Al(OH) 3 and Na 2 CO 3 solution, spare;

[0051] 3) The solid Al(OH) obtained in step 2) 3 Dissolved in 30% H 2 SO 4 solution until solid A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com