A kind of preparation method of conductive nylon material

A nylon and raw material technology, applied in the field of preparation of conductive nylon materials, can solve problems such as poor electrical conductivity, and achieve the effects of improving electrical conductivity, reducing surface resistance, and improving compatibility and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

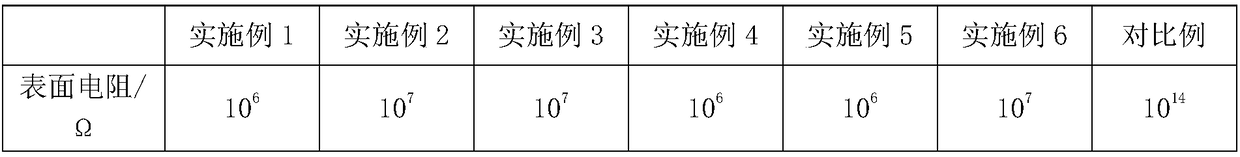

Examples

Embodiment 1

[0026] Conductive nylon material was prepared according to the following steps:

[0027] (1) Add n-bromobutane and N-vinylimidazole with a volume ratio of 1:1.5 into the flask, heat to 55°C and react for 20 hours, wash the obtained product with ethyl acetate, spin evaporate for 4 hours, and vacuum dry After drying to obtain an intermediate product, add the intermediate product and the initiator AIBN to ethanol, the mass ratio of the intermediate product, the initiator AIBN, and ethanol is 1:0.02:40, heat to 75°C under the protection of nitrogen and react for 8 hours, and the obtained The product was washed with methanol and then vacuum-dried to obtain an ionic liquid for subsequent use;

[0028] (2) Place the carbon nanotubes in a calcination furnace, heat up to 400° C. for 2 hours in an oxygen atmosphere to obtain calcined carbon nanotubes, put the calcined carbon nanotubes into a crucible, and mix concentrated nitric acid with a volume ratio of 1:3, Concentrated sulfuric ac...

Embodiment 2

[0034] Conductive nylon material was prepared according to the following steps:

[0035] (1) Add n-bromobutane and N-vinylimidazole with a volume ratio of 1:1.5 into the flask, heat to 55°C and react for 20 hours, wash the obtained product with ethyl acetate, spin evaporate for 4 hours, and vacuum dry After drying to obtain an intermediate product, add the intermediate product and the initiator AIBN to ethanol, the mass ratio of the intermediate product, the initiator AIBN, and ethanol is 1:0.02:40, heat to 75°C under the protection of nitrogen and react for 8 hours, and the obtained The product was washed with methanol and then vacuum-dried to obtain an ionic liquid for subsequent use;

[0036](2) Place the carbon nanotubes in a calcination furnace, heat up to 400° C. for 2 hours in an oxygen atmosphere to obtain calcined carbon nanotubes, put the calcined carbon nanotubes into a crucible, and mix concentrated nitric acid with a volume ratio of 1:3, Concentrated sulfuric aci...

Embodiment 3

[0042] Conductive nylon material was prepared according to the following steps:

[0043] (1) Add n-bromobutane and N-vinylimidazole with a volume ratio of 1:1.5 into the flask, heat to 55°C and react for 20 hours, wash the obtained product with ethyl acetate, spin evaporate for 4 hours, and vacuum dry After drying to obtain an intermediate product, add the intermediate product and the initiator AIBN to ethanol, the mass ratio of the intermediate product, the initiator AIBN, and ethanol is 1:0.02:40, heat to 75°C under the protection of nitrogen and react for 8 hours, and the obtained The product was washed with methanol and then vacuum-dried to obtain an ionic liquid for subsequent use;

[0044] (2) Place the carbon nanotubes in a calcination furnace, heat up to 400° C. for 2 hours in an oxygen atmosphere to obtain calcined carbon nanotubes, put the calcined carbon nanotubes into a crucible, and mix concentrated nitric acid with a volume ratio of 1:3, Concentrated sulfuric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com