A method for preparing a carbon crystal anti-slip ramp

A carbon crystal, anti-slip technology, applied in the field of coatings, can solve the problems of short coating life in the open air, poor light aging resistance, harmful to human health, etc., and achieve good volatilization speed and wettability, low air permeability, and shielding isolation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0040] A method for preparing a carbon crystal anti-slide slope, comprising the following steps in sequence:

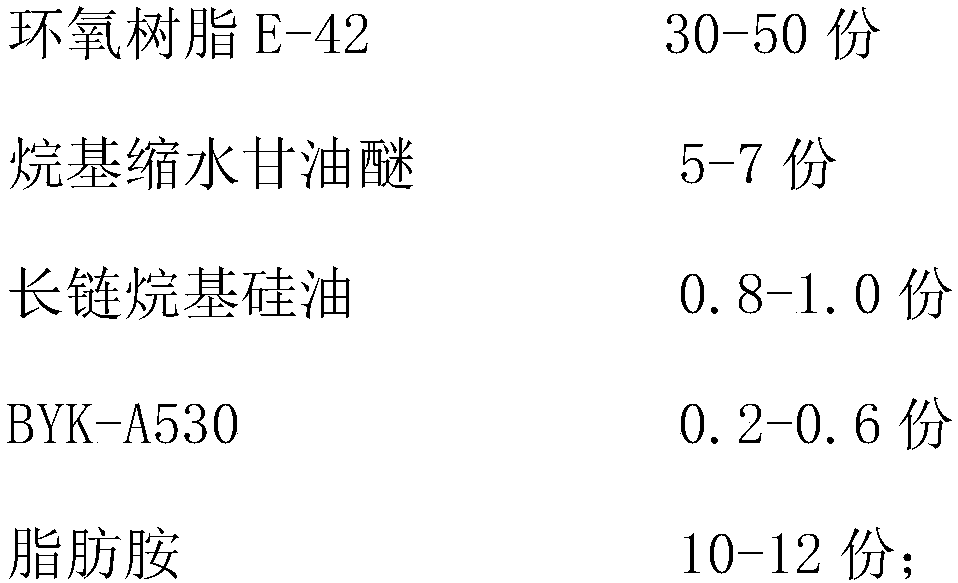

[0041] S1: Preparation of primer: add 30-50 parts of epoxy resin E-42, 5-7 parts of alkyl glycidyl ether, 0.8-1.0 parts of long-chain alkyl silicone oil, 0.2- 0.6 parts, 10-12 parts of fatty amine; disperse for 20-30 minutes at the speed of 1000-1200r / min;

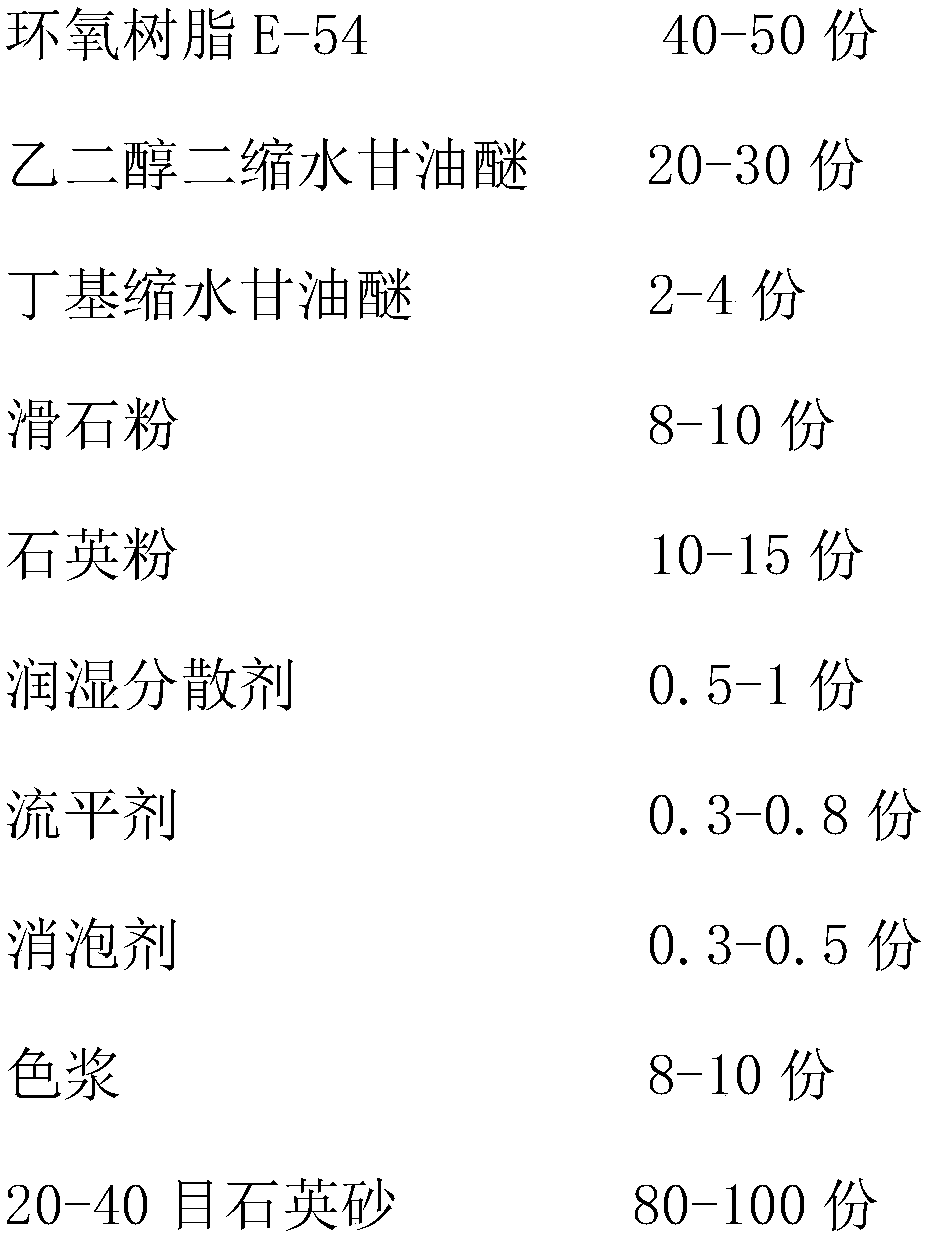

[0042] S2: Preparation of component A: Add 40-50 parts of epoxy resin E-54, 20-30 parts of ethylene glycol diglycidyl ether, 2-4 parts of butyl glycidyl ether, and 8 parts of talc into the second dispersion container -10 parts, 10-15 parts of quartz powder, 0.5-1 part of wetting and dispersing agent, 0.3-0.8 parts of leveling agent, 0.3-0.5 parts of defoamer, 8-10 parts of color paste, 80 parts of 20-40 mesh quartz sand -100 parts, 40-50 parts of carbon crystals; disperse at a speed of 1200-1800r / min for 18-22 minutes until uniformly mixed;

[0043] S3: Prepare component B: add 10-20 parts of diethylenetriamine ...

Embodiment 1

[0049] A method for preparing a carbon crystal anti-slide slope, comprising the following steps in sequence:

[0050] S1: Preparation of primer: Add 40 parts of epoxy resin E-42, 6 parts of alkyl glycidyl ether, 0.9 part of long-chain alkyl silicone oil, 0.4 part of BYK-A530, and 11 parts of fatty amine into the first dispersion container; Disperse for 25 minutes at a rotating speed of 1100r / min;

[0051]S2: Preparation of component A: Add 45 parts of epoxy resin E-54, 25 parts of ethylene glycol diglycidyl ether, 3 parts of butyl glycidyl ether, 9 parts of talc powder, and 13 parts of quartz powder into the second dispersion container , 0.75 parts of wetting and dispersing agent, 0.55 parts of leveling agent, 0.4 parts of defoamer, 9 parts of color paste, 90 parts of 20-40 mesh quartz sand, 45 parts of carbon crystal; disperse at 1500r / min for 20 minutes to well mixed;

[0052] S3: Prepare component B: add 15 parts of diethylenetriamine and 1.2 parts of n-butyric acid to th...

Embodiment 2

[0056] A method for preparing a carbon crystal anti-slide slope, comprising the following steps in sequence:

[0057] S1: Preparing the base coat: add 35 parts of epoxy resin E-42, 5.7 parts of alkyl glycidyl ether, 0.88 parts of long-chain alkyl silicone oil, 0.3 parts of BYK-A530, and 11.5 parts of fatty amine into the first dispersion container; Disperse for 28 minutes at a rotating speed of 1150r / min;

[0058] S2: Preparation of component A: add 48 parts of epoxy resin E-54, 28 parts of ethylene glycol diglycidyl ether, 2.5 parts of butyl glycidyl ether, 8.8 parts of talc powder, and 12 parts of quartz powder into the second dispersion container , 0.8 parts of wetting and dispersing agent, 0.5 parts of leveling agent, 0.35 parts of defoamer, 8.8 parts of color paste, 88 parts of 20-40 mesh quartz sand, 48 parts of carbon crystal; disperse at 1500r / min for 21 minutes to well mixed;

[0059] S3: Prepare component B: add 18 parts of diethylenetriamine and 1.4 parts of n-but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com