A kind of high-acid heavy crude oil decalcification agent and preparation method thereof

A crude oil decalcifier, heavy technology, applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil and other directions, can solve the problems affecting the normal operation of the device, catalyst poisoning, industrial equipment corrosion, etc., to achieve good economic and social benefits, Good biodegradability and low corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of dithiocarbamic acid modified chitosan:

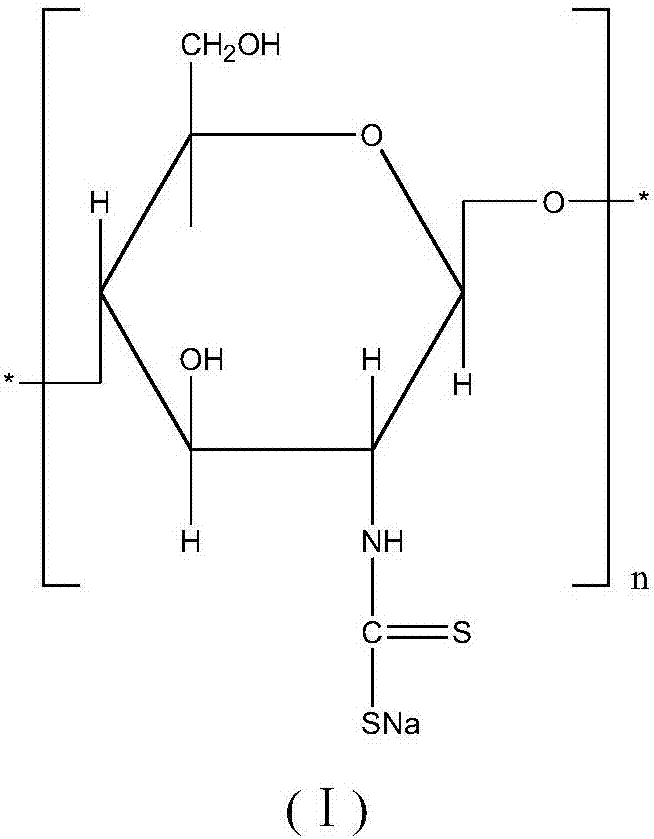

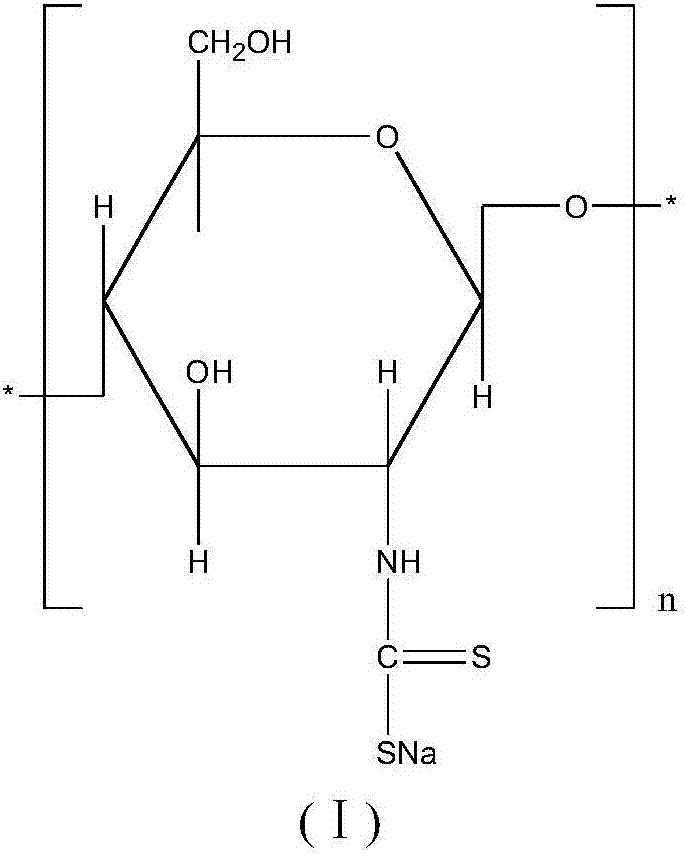

[0028] Dissolve 2.5 g of chitosan in 250 mL of methanol solvent, add it to a four-necked flask, add 25 mL of 40% NaOH solution with constant stirring, and then slowly add 15 mL of CS using a separatory funnel. 2 After the addition, keep the reaction temperature at 30°C and continue the reaction for 10 hours. After the reaction is completed, the product is washed repeatedly with methanol and ethanol, and finally dehydrated with acetone, and dried under vacuum conditions to obtain dithiocarbamic acid modified chitosan having the structure of the following formula (I).

[0029]

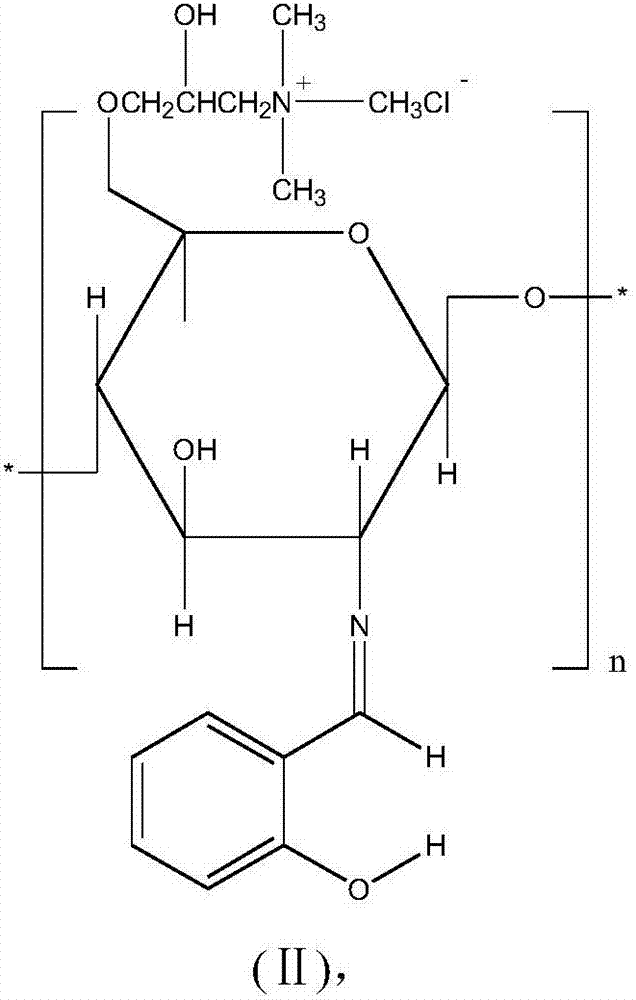

[0030] 2. Preparation of quaternized salicyl chitosan Schiff base:

[0031] (1) In a three-necked flask equipped with a stirrer and a reflux condenser, add 2.5g of chitosan, 75mL of 2% acetic acid solution, 125mL of methanol and 18g of salicylaldehyde in sequence, and react at 60℃. 18h. After the reaction is completed, the product is repeatedly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com