Gas saving, emission reducing and efficiency improving system for industrial gas furnace and kiln

An industrial gas and combustion system technology, which is applied in the chemical industry, petroleum industry, and the manufacture of combustible gas, etc., can solve the problems of quality deterioration, plant leaves withering and falling off, and leaf necrosis spots, etc., and achieve the effect of reducing density differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

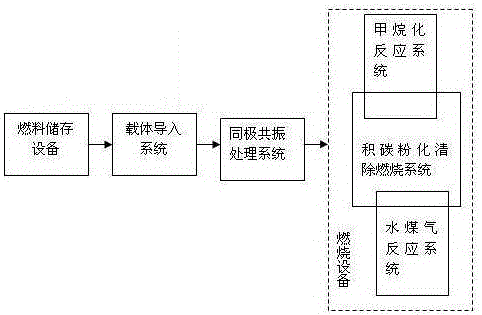

[0033] As shown in the accompanying drawings, an industrial gas-fired furnace gas-saving, emission-reduction and efficiency-enhancing system includes a carrier introduction system, a homopolar resonance treatment system, a methanation reaction system, a water gas reaction system, and a carbon deposition pulverization and removal combustion system;

[0034] The carrier introduction system is equipped with a known liquid carrier, and is connected to the fuel storage device through the fuel inlet, and the carrier introduction system is connected to the homopolar resonance processing system; the homopolar resonance processing system is then connected to the methanation reaction system and the water gas treatment system; The methanation treatment system and the water gas treatment system are located in the same combustion equipment, and the carbon deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com