Extruded puffed food and preparation technology thereof

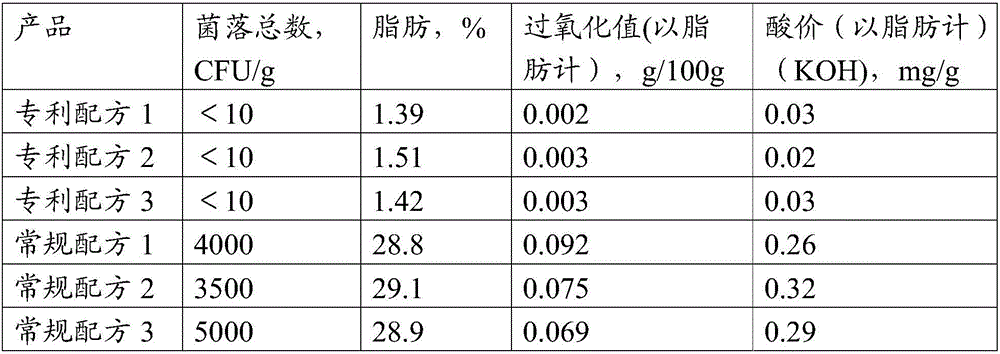

A preparation process and puffed food technology, which is applied in the food field, can solve the problems of microbial contamination of extruded puffed food, prolong product shelf life, reduce production costs, etc., and achieve the effects of reducing oil content, reducing equipment costs, and eating healthier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

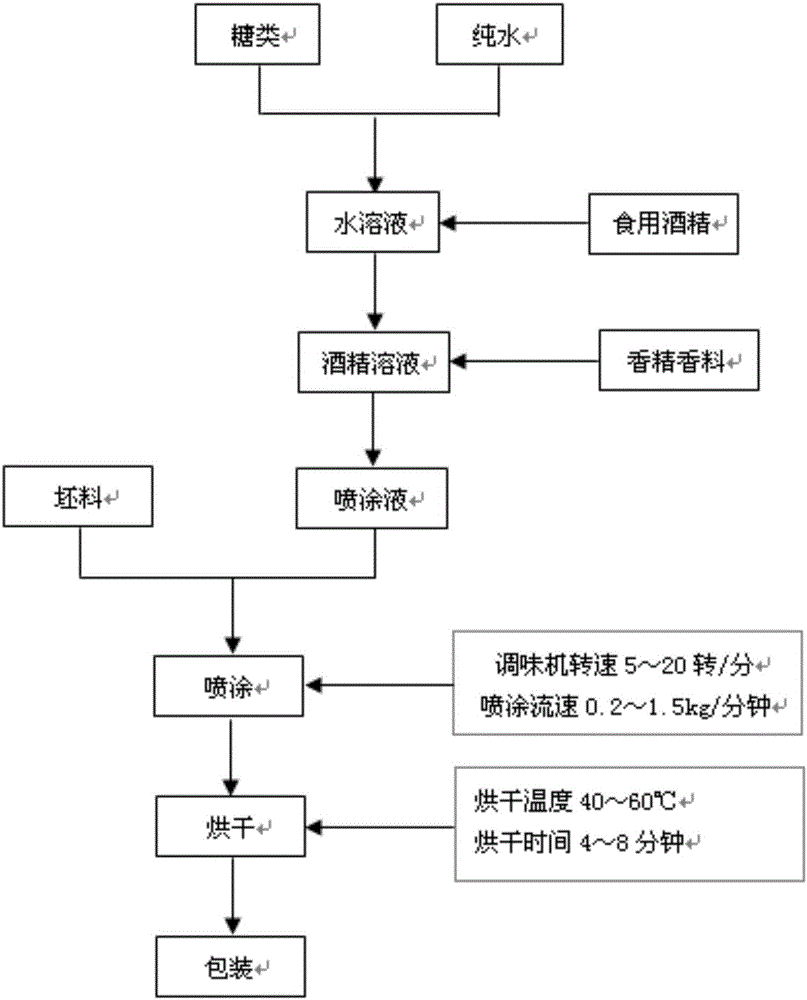

[0028] The invention provides a preparation process of extruded puffed food, comprising the following steps:

[0029] A) mixing 6-25 parts by mass of water, 0-15 parts by mass of carbohydrates, 57.5-76.5 parts by mass of edible alcohol and 0.5-2.5 parts by mass of flavors and fragrances to obtain a spraying liquid;

[0030] B) After spraying the spraying liquid on the surface of the extruded billet, drying it to obtain the extruded puffed food.

[0031] Combine the following figure 1 The preparation process provided by the invention is described in detail, figure 1 It is a flow chart of the preparation process of the extruded puffed food provided by the present invention.

[0032] In the present invention, firstly, 6-25 parts by mass of water, 0-15 parts by mass of carbohydrates, 57.5-76.5 parts by mass of edible alcohol and 0.5-2.5 parts by mass of essence and fragrance are mixed to obtain a spraying liquid;

[0033] Wherein, the step A) is specifically:

[0034] A1) mixi...

Embodiment 1

[0064] Dissolve 15 kg of white granulated sugar in 25 kg of pure water, add 57.5 kg of edible alcohol with a concentration of 95%, stir for 10 to 20 minutes at a stirring speed of 35 rpm, and then put in 2.5 kg of powdered essence and fragrance through a 200-mesh sieve and stir for 10 to 20 minutes. Stirring was continued in the storage tank at a stirring speed of 35 rpm to obtain a spraying liquid.

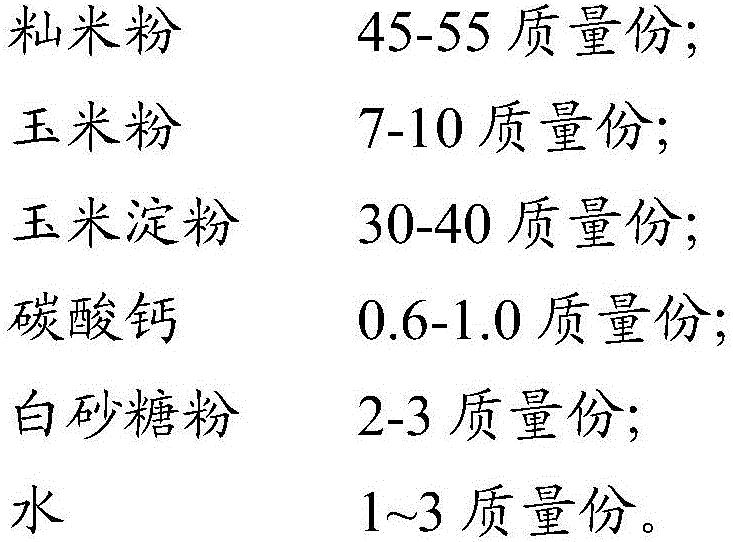

[0065] Crush the indica rice, pass through a 80-mesh sieve, weigh 50kg of indica rice flour, 8.5kg of corn flour (more than 80 mesh), 36.2kg of cornstarch, 0.8kg of calcium carbonate, and 2.5kg of white sugar powder, and mix them in a mixer for 5 minutes at a speed of 18rpm , add water 2kg and stir for 5min. The mixture is put into the extrusion extruder, the extruding temperature: 50°C in the first zone, 130°C in the second zone, 130°C in the third zone, feeding frequency: 30Hz, cutting frequency: 50Hz. Blank 1 was obtained, and blank 2 was obtained after drying at 60° C. for 4...

Embodiment 2

[0068] Dissolve 15kg of fructose in 6kg of pure water, add 76.5kg of edible alcohol with a concentration of 95%, stir for 10 to 20 minutes at a stirring speed of 35rpm, and then put in 2.5kg of powdered flavor and fragrance through a 200-mesh sieve and stir for 10 to 20 minutes for storage Stirring was continued in the feed tank at a stirring speed of 35 rpm to obtain a spray coating liquid.

[0069] Crush the indica rice, pass through a 80-mesh sieve, weigh 50kg of indica rice flour, 8.5kg of corn flour (more than 80 mesh), 36.2kg of cornstarch, 0.8kg of calcium carbonate, and 2.5kg of white sugar powder, and mix them in a mixer for 5 minutes at a speed of 18rpm , add water 2kg and stir for 5min. The mixture is put into the extrusion extruder, the extruding temperature: 50°C in the first zone, 130°C in the second zone, 130°C in the third zone, feeding frequency: 30Hz, cutting frequency: 50Hz. Blank 1 was obtained, and blank 2 was obtained after drying at 60° C. for 4 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com