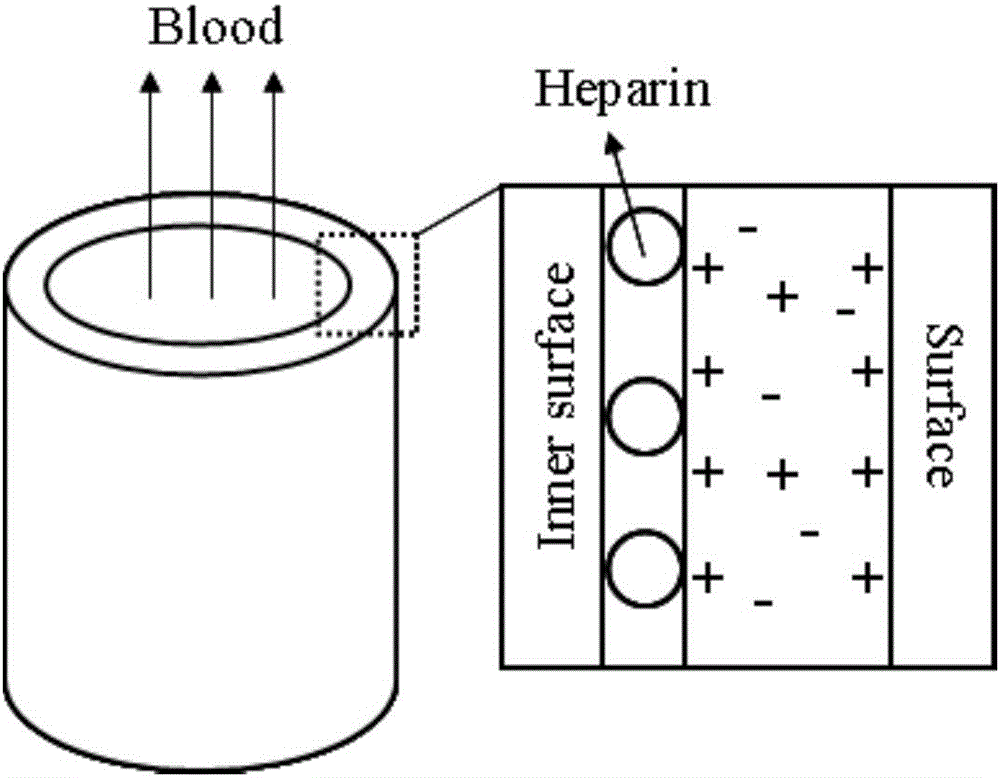

Surface heparinization hemodialysis film and preparation method thereof

A technology of hemodialysis and heparinization, applied in chemical instruments and methods, dialysis systems, semi-permeable membrane separation, etc., can solve the problems of low removal efficiency and poor anti-bacterial pollution ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of cellulose quaternary ammonium salt

[0029] A 12% NaOH-urea solution was prepared, 0.2g of cellulose was accurately weighed and added to 10g of the above-mentioned NaOH-urea solution, and placed in a refrigerator at -20°C for 2h. After being taken out, it was solid, and after stirring and dissolving vigorously for 10 minutes under the stirring state of a stirring blade, the resulting solution was a cellulose-NaOH-urea solution with a concentration of 2% (based on the mass fraction of cellulose in NaOH-urea). Weigh a certain amount of CHPAC, first prepare it into an aqueous solution with a mass fraction of 40%, add the aqueous solution dropwise to the cellulose-NaOH-urea solution under vigorous stirring, and stir for reaction overnight (12h) at room temperature. After the reaction, the reaction system was transferred to a dialysis bag with a molecular weight cut-off of 8000, and dialyzed with deionized water for 15 times with an interval of more than 3 ho...

Embodiment 2

[0037] (1) Preparation of cellulose quaternary ammonium salt / polyacrylic acid film

[0038] Take 80 mg of the cellulose quaternary ammonium salt obtained in step (1) of Example 1, 120 mg of ionic liquid (BMIM) Cl, and prepare an 8% cellulose quaternary ammonium salt-12% ionic liquid solution (1 ml), and weigh 0.0040 g of Example 1 The polyacrylic acid obtained in step (2) was mixed, stirred at 78°C (1000 r / min) to dissolve, centrifuged at 3000 r / min for 5 minutes to remove bubbles, poured into a mold, placed at 18°C for 2 hours, and 75% ethanol was added to form a film.

[0039] (2) Surface grafted heparin

[0040] Heparin (titer> 160U / mg) was prepared with deionized water to prepare a polyanion solution with a concentration of 3mg / mL, 0.14mol / L NaCl, and a pH of 5.0. Inject the above polyanion solution into the inner cavity of step (1) cellulose quaternary ammonium salt / polyacrylic acid membrane, react at 20°C for 0.5h, wash the inner surface of the membrane with deionized water,...

Embodiment 3

[0042] (1) Preparation of cellulose quaternary ammonium salt / polyacrylic acid film

[0043] Take 160 mg of cellulose quaternary ammonium salt, 200 mg of ionic liquid (BMIM) Cl to prepare a 16% cellulose quaternary ammonium salt-20% ionic liquid solution (1 ml), and weigh 0.0040 g of the polyacrylic acid obtained in step (2) of Example 1 , Mix, stir at 78°C (1000r / min) to dissolve, centrifuge at 3000r / min for 5min to remove bubbles, pour it into a mold, place it at 18°C for 2h, add 75% ethanol to form a film.

[0044] (2) Surface grafted heparin

[0045] Heparin (titer> 160U / mg) was prepared with deionized water to prepare a polyanion solution with a concentration of 4mg / mL, 0.14mol / L NaCl, and a pH of 5.5. Inject the above polyanion solution into the inner cavity of step (1) cellulose quaternary ammonium salt / polyacrylic acid membrane, react at 20°C for 0.5h, wash the inner surface of the membrane with deionized water, and repeat the steps of injecting heparin solution, reaction a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com