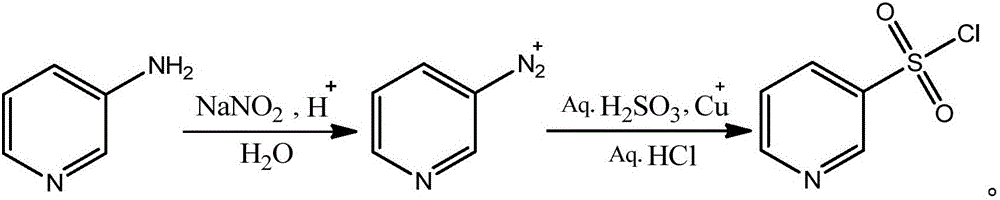

Environment-friendly chemical synthetic method for 3-pyridine sulfonyl chloride

A technology of pyridinesulfonyl chloride and green chemistry, applied in the direction of organic chemistry, can solve the problems of unfriendly environment, foul smell, high energy consumption, etc., and achieve the effects of reducing production costs, mild reaction conditions, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

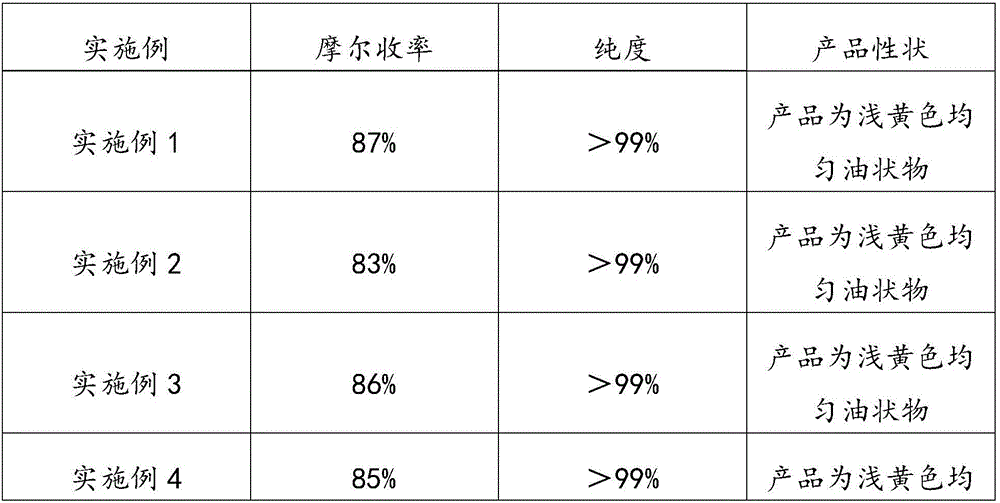

Examples

Embodiment 1

[0055] A green chemical synthesis method of 3-pyridinesulfonyl chloride, including the following steps:

[0056] Step A: Add 300kg of water to the reactor, and then pass in 200kg of sulfur dioxide after cooling to -10°C. During the process of passing in sulfur dioxide, the temperature is controlled not to be higher than 8°C. After the passage is completed, stir and add 211g of cuprous chloride to obtain sulfurous acid Aqueous solution, ready for use;

[0057] Step B: Add 63.76kg of 36% hydrochloric acid in another reactor, add 20kg of 3-aminopyridine, cool to -10°C, dropwise add sodium nitrite aqueous solution (containing 14.67kg sodium nitrite, 30kg water), The temperature of the dripping process is controlled not to be higher than 5℃, after the dripping is completed, the temperature is controlled to not higher than 5℃ for use;

[0058] Step C: Add the solution obtained in step B dropwise to the reactor of step A. The temperature of the dropping process is controlled at -5°C. After...

Embodiment 2

[0061] A green chemical synthesis method of 3-pyridinesulfonyl chloride, including the following steps:

[0062] Step A: Add 500kg of water to the reactor, add 126.43kg of thionyl chloride dropwise after cooling to 10°C, control the temperature at 0°C during the dropwise addition of thionyl chloride, add 422g cuprous chloride with stirring after the addition is complete , To obtain an aqueous solution of sulfurous acid, ready for use;

[0063] Step B: Add 106.27kg of hydrochloric acid with a mass fraction of 36% in another reactor, add 20kg of 3-aminopyridine, cool to 5°C, add dropwise sodium nitrite aqueous solution (containing 29.33kg sodium nitrite, 60kg water), dropwise During the addition, control the temperature at -5°C, after the addition is completed, control the temperature at -5°C, and set it aside;

[0064] Step C: Add the solution obtained in step B dropwise to the reactor of step A. The temperature of the dropping process is controlled at 5°C. After the dropping is comp...

Embodiment 3

[0067] A green chemical synthesis method of 3-pyridinesulfonyl chloride, including the following steps:

[0068] Step A: Add 350kg of water to the reactor, add 101.15kg of thionyl chloride dropwise after cooling to -5°C, control the temperature to 8°C during the dropwise addition of thionyl chloride, add 211g cuprous chloride after the addition is complete , To obtain an aqueous solution of sulfurous acid, ready for use;

[0069] Step B: Add 74.39kg of 36% hydrochloric acid in another reactor, add 20kg of 3-aminopyridine, cool to -10°C, dropwise add sodium nitrite aqueous solution (containing 14.67kg sodium nitrite, 30kg water), During the dropping process, the temperature is controlled at 5°C, after the dropping is completed, the temperature is controlled at 5°C, ready for use;

[0070] Step C: Add the solution obtained in step B dropwise to the reactor of step A. The temperature of the dropping process is controlled at -3°C. After the dropping is completed, the reaction is stirred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com