Comprehensive extraction method for fructus gardeniae

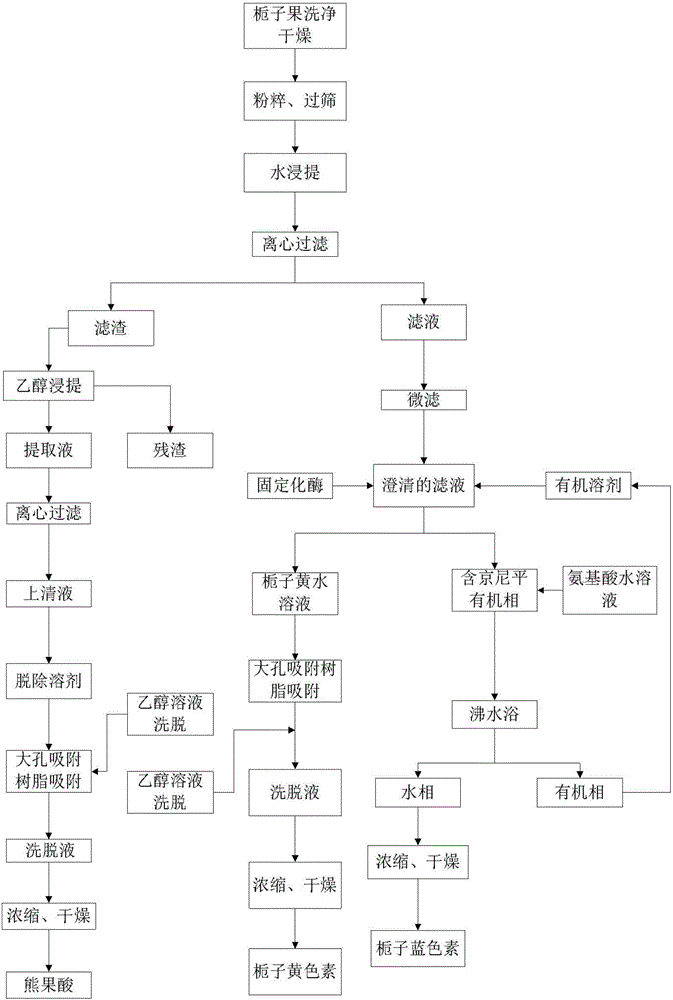

A technology of comprehensive extraction and water gardenia, applied in chemical instruments and methods, steroids, food science, etc., can solve the problems of complicated process and failure of comprehensive extraction and utilization of active ingredients, and achieve high color value and bright color of pigment , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Wash and dry the water gardenia and crush it through a 40-mesh sieve to obtain the water gardenia powder, then add water with a solid-to-liquid ratio (w / v) of 1:5, and extract once at ultrasonic power 100W and temperature 30°C for 1 hour Finally, the leaching liquid was separated from the solid and liquid through a centrifuge (rotating speed: 8000 rpm, 5 min), and the filtrate was collected to obtain a filter residue. The filtrate was first filtered with an inorganic ceramic microfiltration membrane (MF) with a pore size of 0.5 μm, the operating temperature was 30°C, and the pressure: 0.4Mpa; The immobilized β-glucosidase (0.937U / mL, pH5.0) as the carrier was mixed as the aqueous phase-n-octanol was the organic phase (ratio 1:1), hydrolyzed at 40°C for 40min (100rpm). Add 0.05 mol / L glycine solution (v / v2:1) to the extracted organic phase, and react for 20 minutes in a constant temperature water bath at 80°C to obtain a gardenia blue pigment solution, which is then spra...

Embodiment 2

[0055] After washing and drying the water gardenia, crush it through a 40-mesh sieve to obtain water gardenia powder, then add water with a solid-to-liquid ratio (w / v) of 1:15, and extract 3 times at an ultrasonic power of 200W and a temperature of 50°C. After 1 hour, pass the extract solution through a centrifuge (speed: 15000 rpm, 20 minutes) for solid-liquid separation, collect the filtrate, and obtain a filter residue. The filtrate was first filtered with an inorganic ceramic microfiltration membrane (MF) with a pore size of 0.5 μm, the operating temperature was 60°C, and the pressure: 0.9Mpa; The immobilized β-glucosidase (4.347U / mL, pH5.0) as the carrier was mixed as the aqueous phase-n-octanol was the organic phase (compared to 1:5), hydrolyzed at 60°C for 200min (250rpm). Add 0.05 mol / L glycine solution (v / v1:1) to the extracted organic phase, and react for 55 minutes in a constant temperature water bath at 100°C to obtain a gardenia blue pigment solution, which is con...

Embodiment 3

[0059] Wash and dry Jasmine jasminoides, crush and pass through a 40-mesh sieve to obtain jasmine jasmine powder, then add water with a solid-to-liquid ratio (w / v) of 1:8, and extract twice at an ultrasonic power of 120W and a temperature of 35°C. After 1 hour, pass the extract liquid through a centrifuge (speed: 8000 rpm, 10 min) for solid-liquid separation, collect the filtrate, and obtain a filter residue. The filtrate was first filtered with an inorganic ceramic microfiltration membrane (MF) with a pore size of 0.5 μm, the operating temperature was 35°C, and the pressure: 0.5Mpa; The immobilized β-glucosidase (4.329U / mL, pH5.0) as the carrier was mixed as the aqueous phase-n-octanol was the organic phase (compared to 1:2), hydrolyzed at 45°C for 60min (180rpm). Add 0.2 mol / L glycine solution (v / v2:1) to the extracted organic phase, and react for 40 minutes in a constant temperature water bath at 85°C to obtain a gardenia blue pigment solution, which is concentrated and spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com