Technology for extracting cordyceps polysaccharide from Paecilomyces hepiali fermentation broth

A technology of Paecilomyces spp. and Cordyceps polysaccharides, applied in the biological field, can solve the problems of low purity of finished products of Cordyceps polysaccharides, low extraction rate of Cordyceps polysaccharides, unfavorable mass production, etc., achieve low cost, less loss of polysaccharides, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

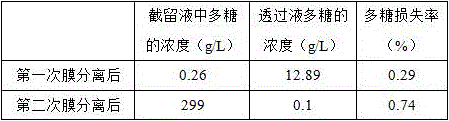

Embodiment 1

[0033] Example 1 A process for extracting Cordyceps polysaccharide from the fermentation broth of Paecilomyces hematalis

[0034] Extracting the Cordyceps polysaccharide from the Paecilomyces batata fermented liquid comprises the following steps:

[0035] Step 1 Beating

[0036] The formula for the fermentation of Paecilomyces hematalis is 20% potato, 2% soybean flour, 1% sucrose, 0.3% KH 2 PO 4 , 0.15%MgSO 4 ·7H 2 O, 0.001% vitamin B1, and water make up the balance; the above-mentioned percentages are mass percentages; after the fermentation is completed, a fermented liquid is obtained.

[0037] Adjust the pressure of the fermenter to 0.03MPa, adjust the pressure of the beater to zero, and use the pressure difference to press 1000L of the fermented Paecilomyces hematodes fermentation liquid into the beater; add water equal to the volume of the fermentation liquid, turn on the beater for beating, and beat to a homogenous state;

[0038] The rotation speed during beating ...

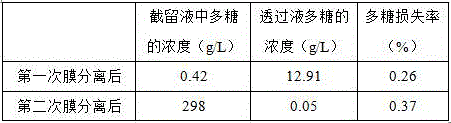

Embodiment 2

[0058] Example 2 A process for extracting Cordyceps polysaccharide from the fermentation broth of Paecilomyces hematalis

[0059] Extracting the Cordyceps polysaccharide from the Paecilomyces batata fermented liquid comprises the following steps:

[0060] Step 1 Beating

[0061] The formula for the fermentation of Paecilomyces hematalis is 20% potato, 2% soybean flour, 1% sucrose, 0.3% KH 2 PO 4 , 0.15%MgSO 4 ·7H 2O, 0.001% vitamin B1, and water make up the balance; the above-mentioned percentages are mass percentages; after the fermentation is completed, a fermented liquid is obtained.

[0062] Adjust the pressure of the fermenter to 0.03MPa, adjust the pressure of the beater to zero, and use the pressure difference to press 1000L of the fermented Paecilomyces hematodes fermentation liquid into the beater; add water equal to the volume of the fermentation liquid, turn on the beater for beating, and beat to a homogenous state;

[0063] The rotating speed during beating i...

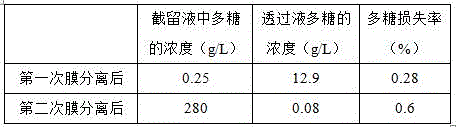

Embodiment 3

[0084] Example 3 A process for extracting Cordyceps polysaccharide from the fermentation broth of Paecilomyces hematalis

[0085] Extracting the Cordyceps polysaccharide from the Paecilomyces batata fermented liquid comprises the following steps:

[0086] Step 1 Beating

[0087] The formula for the fermentation of Paecilomyces hematalis is 20% potato, 2% soybean flour, 1% sucrose, 0.3% KH 2 PO 4 , 0.15%MgSO 4 ·7H 2 O, 0.001% vitamin B1, and water make up the balance; the above-mentioned percentages are mass percentages; after the fermentation is completed, a fermented liquid is obtained.

[0088] Adjust the pressure of the fermenter to 0.03MPa, adjust the pressure of the beater to zero, and use the pressure difference to press 1000L of the fermented Paecilomyces hematodes fermentation liquid into the beater; add water equal to the volume of the fermentation liquid, turn on the beater for beating, and beat to a homogenous state;

[0089] The rotating speed during beating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com