A kind of red fluorescent powder and preparation method thereof

A red light phosphor powder, calcination technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor stability, difficult to obtain, low color rendering performance of white LED devices, and achieve excellent high temperature and high humidity resistance. Low requirements and good luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

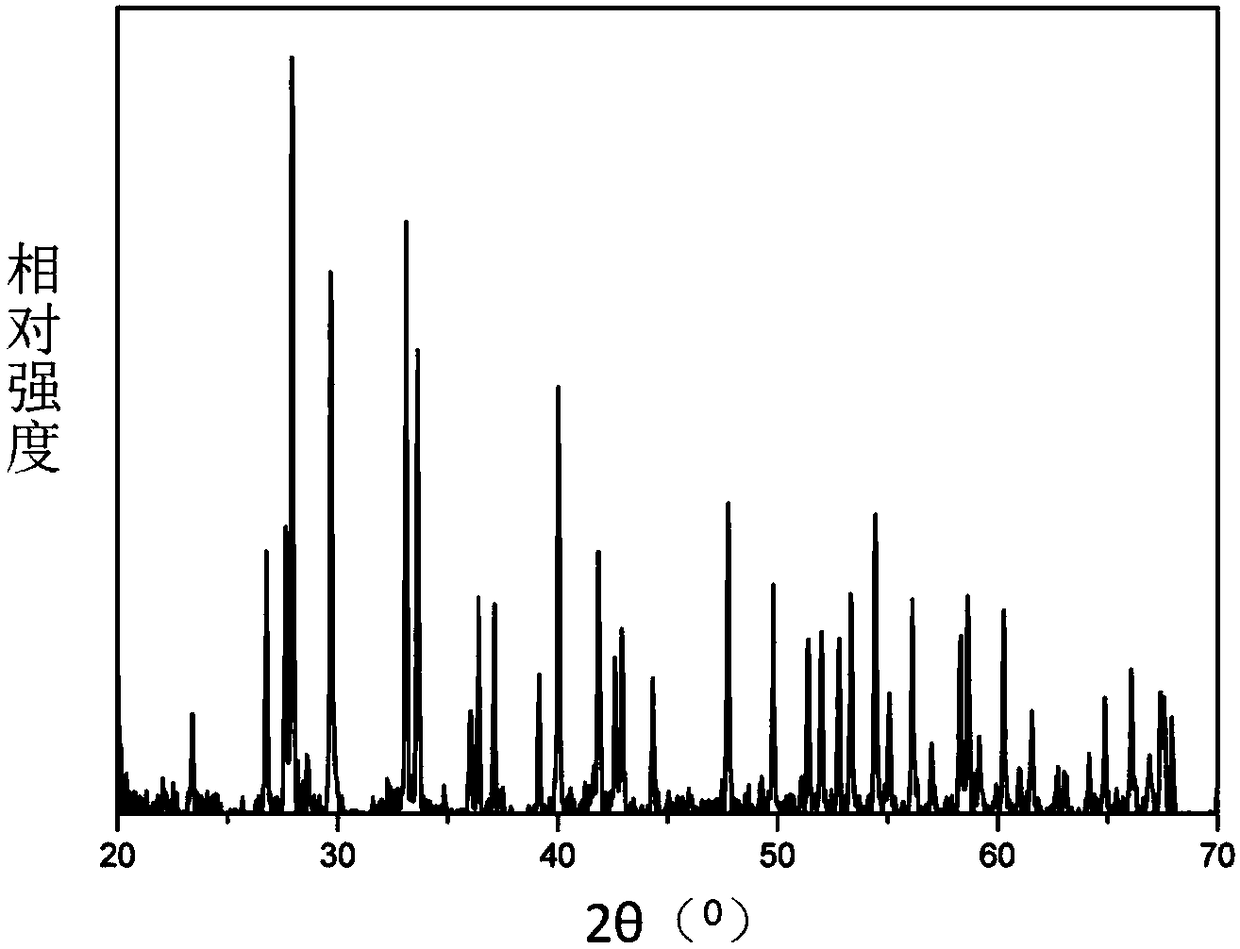

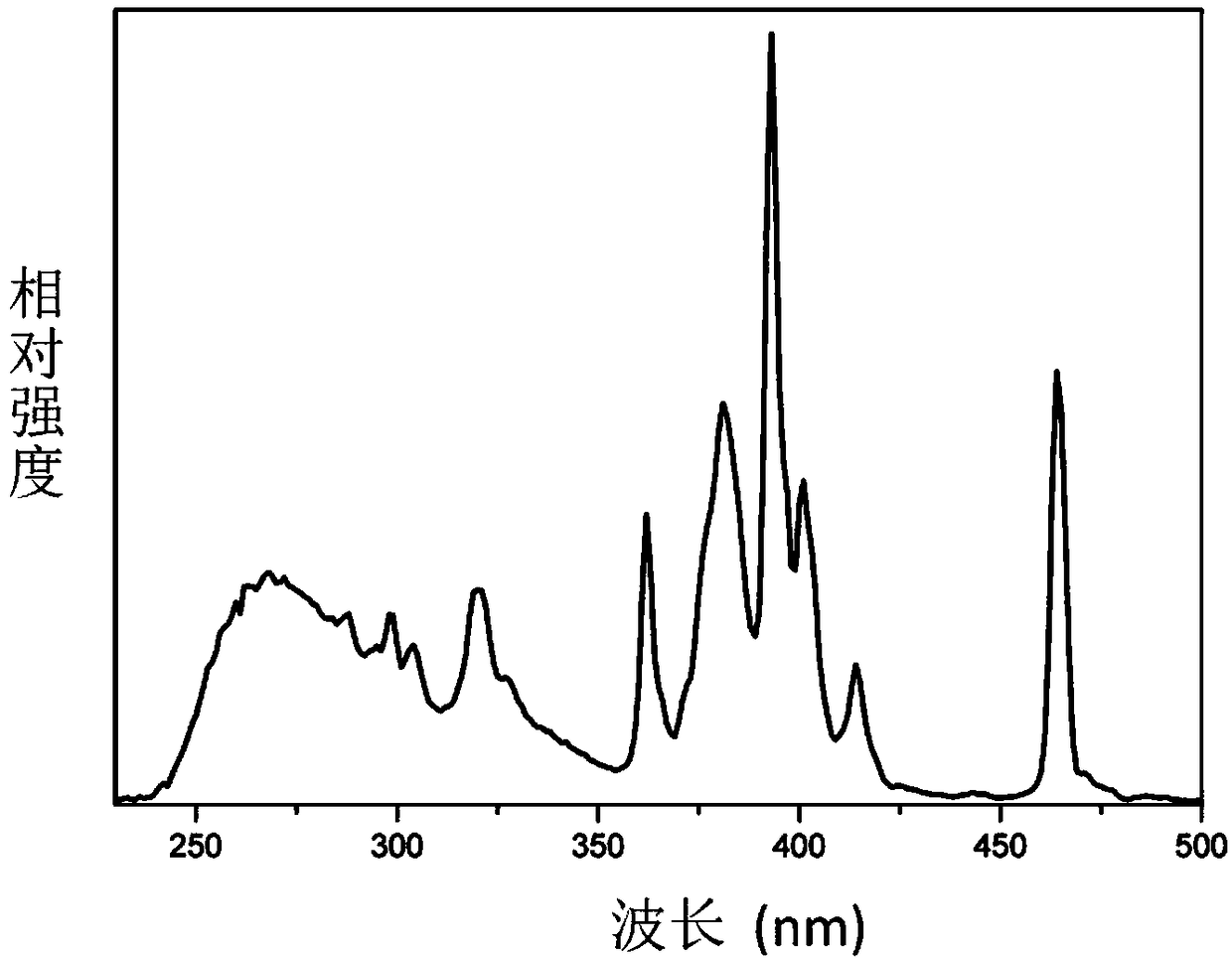

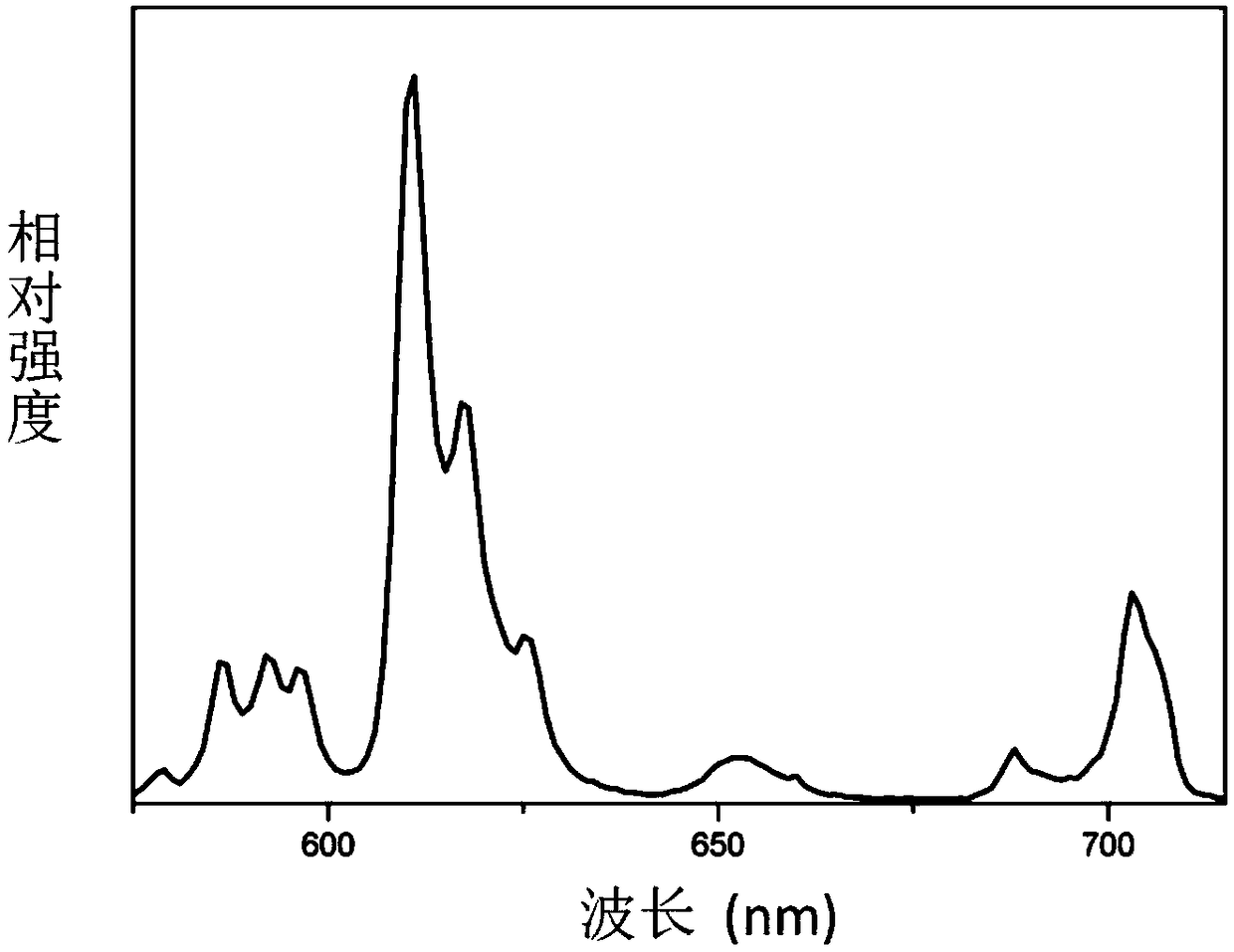

[0027] Weigh 4.997 grams of Yb (NO 3 ) 3 ·6H 2 O and 0.4718 g Eu(NO 3 ) 3 ·6H 2 O was dissolved in 30ml of absolute ethanol, and kept stirring in a water bath at 70°C until it became a colorless and transparent solution; when the transparent solution was cooled to room temperature, 2.4487 grams of tetraethyl orthosilicate was added dropwise, and stirred to make the two solutions Mix well to obtain a mixed solution; add 0.1ml of 2mol / L hydrochloric acid as a catalyst to the mixed solution, and stir at 70°C for 8 hours to form a transparent precursor solution; after aging the precursor solution for 60 hours, dry it in an oven at 60°C After drying for 10 hours, place it in a muffle furnace at 200°C for calcination to obtain a dried gel; after the gel is ground into powder, it is calcined in a high-temperature muffle furnace at a calcination temperature of 1300°C, and the calcined product is ground to D 50 Between 10 and 16 microns, (Yb 0.91 Eu 0.09 ) 2 Si 2 o 7 red fluo...

Embodiment 2

[0030] Weigh 5.4095 grams of Yb (NO 3 ) 3 ·6H 2 O and 0.0522 g Eu(NO 3 ) 3 ·6H 2 O was dissolved in 30ml of absolute ethanol, and stirred continuously in a water bath at 70°C until it became a colorless and transparent solution; when the transparent solution was cooled to room temperature, 2.4367 grams of tetraethyl orthosilicate was added dropwise, and stirred to make the two solutions Mix well to obtain a mixed solution; add 0.1ml of 3mol / L citric acid as a catalyst to the mixed solution, and stir at 70°C for 4 hours to form a transparent precursor solution; after aging the precursor solution for 72 hours, put it in an oven at 70°C After drying for 12 hours, place it in a muffle furnace at 200°C for calcination to obtain a dried gel; after the gel is ground into powder, it is calcined in a high-temperature muffle furnace at a calcination temperature of 1100°C, and the calcined product is ground to D 50 Between 10 and 16 microns, (Yb 0.99 Eu 0.01 ) 2 Si 2 o 7 red fl...

Embodiment 3

[0034] Weigh 4.3713 grams of Yb (NO 3 ) 3 ·6H 2 O and 1.0432 g Eu(NO 3 ) 3 ·6H 2 O was dissolved in 30ml of absolute ethanol, and stirred continuously in a water bath at 70°C until it became a colorless and transparent solution; when the transparent solution was cooled to room temperature, 2.4367 grams of tetraethyl orthosilicate was added dropwise, and stirred to make the two solutions Mix well to obtain a mixed solution; add 0.1ml of 2mol / L hydrochloric acid as a catalyst to the mixed solution, and stir at 70°C for 8 hours to form a transparent precursor solution; after aging the precursor solution for 60 hours, dry it in an oven at 80°C After drying for 8 hours, place it in a muffle furnace at 200°C for calcination to obtain a dried gel; the gel is ground into powder and placed in a high-temperature muffle furnace for calcination at a calcination temperature of 1500°C, and the calcined product is ground to D 50 Between 10 and 16 microns, (Yb 0.8 Eu 0.2 ) 2 Si 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com