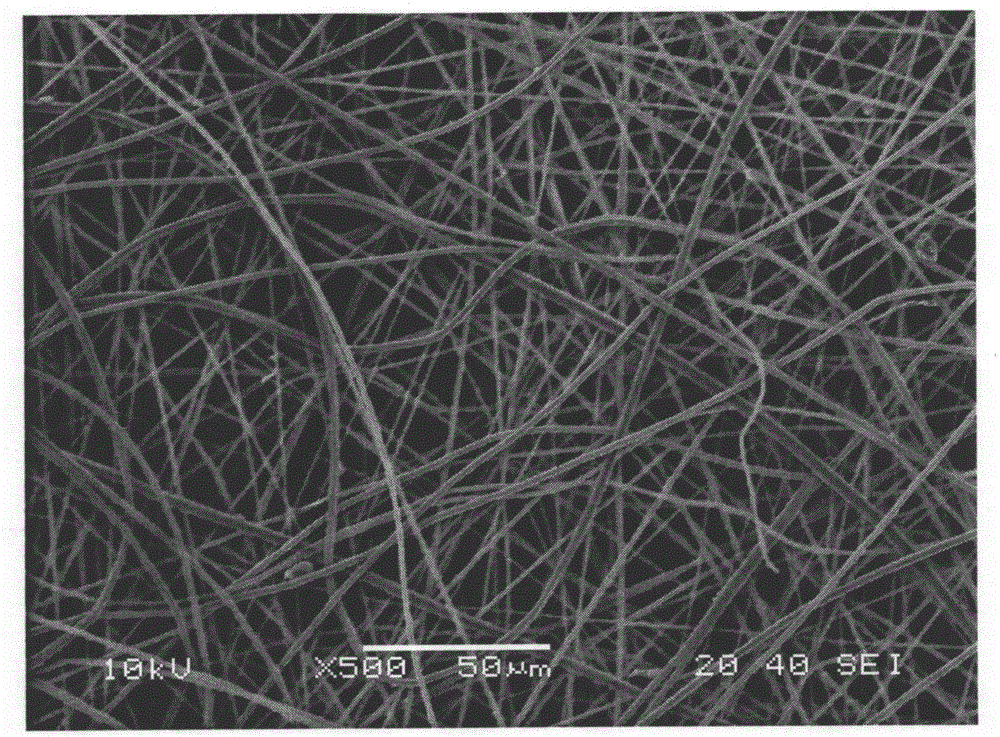

Fluorescent nano-fiber membrane and preparation method thereof

A technology of fluorescent nanofibers and fluorescent polymers, applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as low content of luminescent groups, difficult processing, difficulties in preparation of fluorescent nanofiber membranes and performance optimization, and achieve the goal of preparation process The effect of controllable process and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

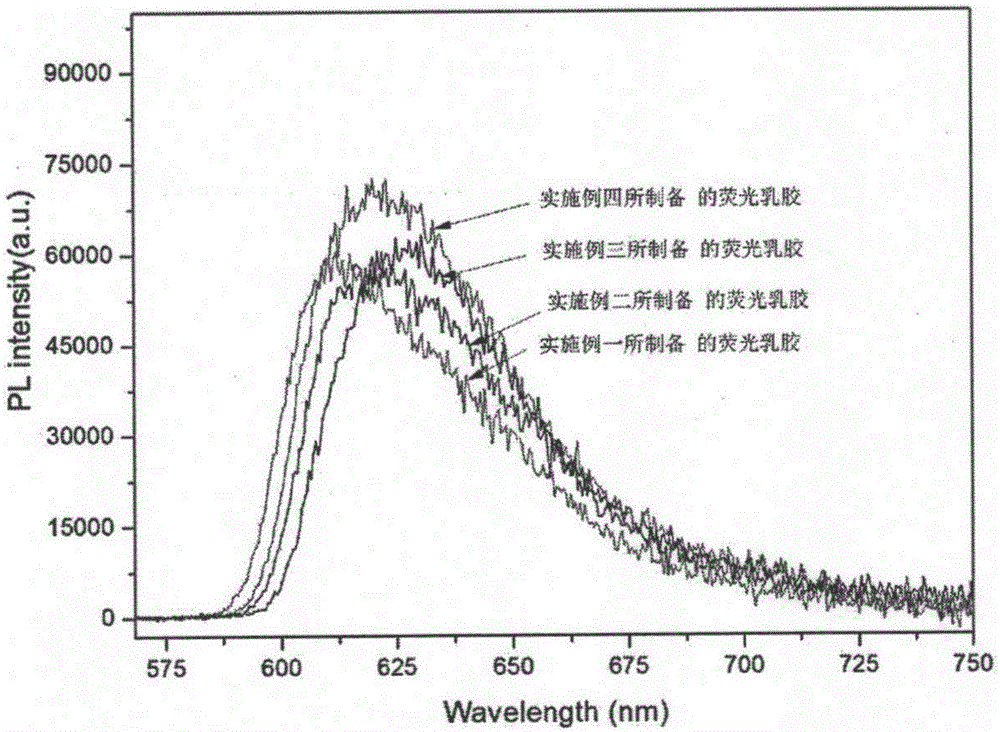

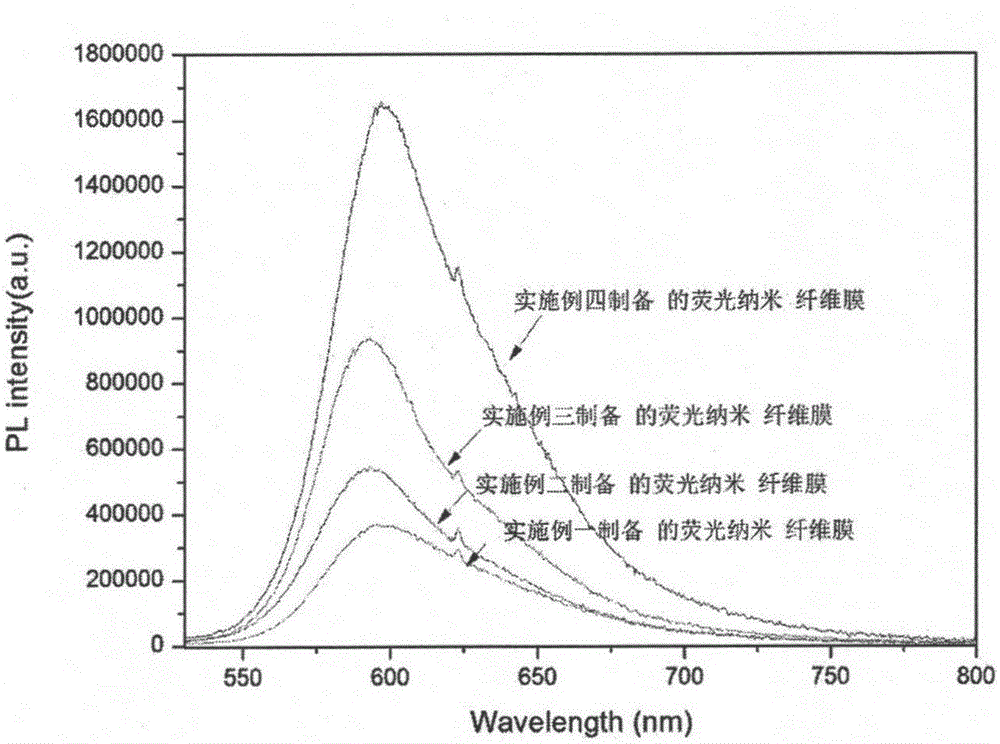

Embodiment 1

[0024] A fluorescent nanofiber film, comprising rhodamine B modified acrylic resin, the mass ratio range between rhodamine B and acrylic resin in the rhodamine B modified acrylic resin is 1:100, and its preparation method for:

[0025] (1) Rhodamine B and acrylic acid monomers are used for emulsion polymerization to obtain fluorescent polymer latex based on Rhodamine B modified acrylic resin:

[0026] Rhodamine B is mixed with acrylic acid monomer in a mass ratio of 1:100, and the acrylic monomer is composed of 35 wt% methyl methacrylate, 60 wt% isooctyl acrylate and 5 wt% methacrylic acid to obtain solution A, Simultaneously with respect to the emulsifier sodium dodecylbenzene sulfonate of solution A quality 1wt% and with respect to solution A quality 1wt% initiator ammonium persulfate is dissolved in the deionized water with the quality of solution A, obtains solution B, Stir and mix evenly; pour solution B into the reaction flask, heat up to 80°C at a speed of 50 rpm, add ...

Embodiment 2

[0032] A fluorescent nanofiber film, comprising rhodamine B modified acrylic resin, the mass ratio between rhodamine B and acrylic resin in the rhodamine B modified acrylic resin is 1:400, and its preparation method for:

[0033] (1) Rhodamine B and acrylic acid monomers are used for emulsion polymerization to obtain fluorescent polymer latex based on Rhodamine B modified acrylic resin:

[0034] Rhodamine B was mixed with acrylic acid monomer in a mass ratio of 1:400, said acrylic monomer was composed of 70 wt% methyl methacrylate, 29 wt% isooctyl acrylate and 1 wt% methacrylic acid to obtain solution A, At the same time, the emulsifier sodium dodecylbenzenesulfonate relative to the solution A quality 2wt% and the initiator ammonium persulfate relative to the solution A quality 0.8wt% are dissolved in deionized water equal to the solution A quality to obtain the solution B , stir and mix evenly; pour solution B into the reaction flask, heat up to 70°C at a speed of 80 rpm, ad...

Embodiment 3

[0039] A fluorescent nanofiber film, comprising rhodamine B modified acrylic resin, the mass ratio range between rhodamine B and acrylic resin in the rhodamine B modified acrylic resin is 1:600, and its preparation method for:

[0040] (1) Rhodamine B and acrylic acid monomers are used for emulsion polymerization to obtain fluorescent polymer latex based on Rhodamine B modified acrylic resin:

[0041] Rhodamine B was mixed with acrylic acid monomer in a mass ratio of 1:600, and the acrylic monomer was composed of 69 wt% methyl methacrylate, 25 wt% isooctyl acrylate and 6 wt% methacrylic acid to obtain solution A, At the same time, the emulsifier sodium dodecylbenzene sulfonate relative to the solution A quality 3wt% and the initiator ammonium persulfate relative to the solution A quality 0.5wt% are dissolved in deionized water with the same quality as the solution A to obtain the solution B , stir and mix evenly; pour solution B into the reaction flask, heat up to 60°C at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com