Karl-Fischer reagent for electrolyte moisture detection and preparation method thereof

A technology of Karl Fischer reagent and electrolyte, which is applied in the field of Karl Fischer reagent for electrolyte moisture detection and its preparation, which can solve the problems of endangering human health, high moisture detection value, and unstable drift value, etc., to ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

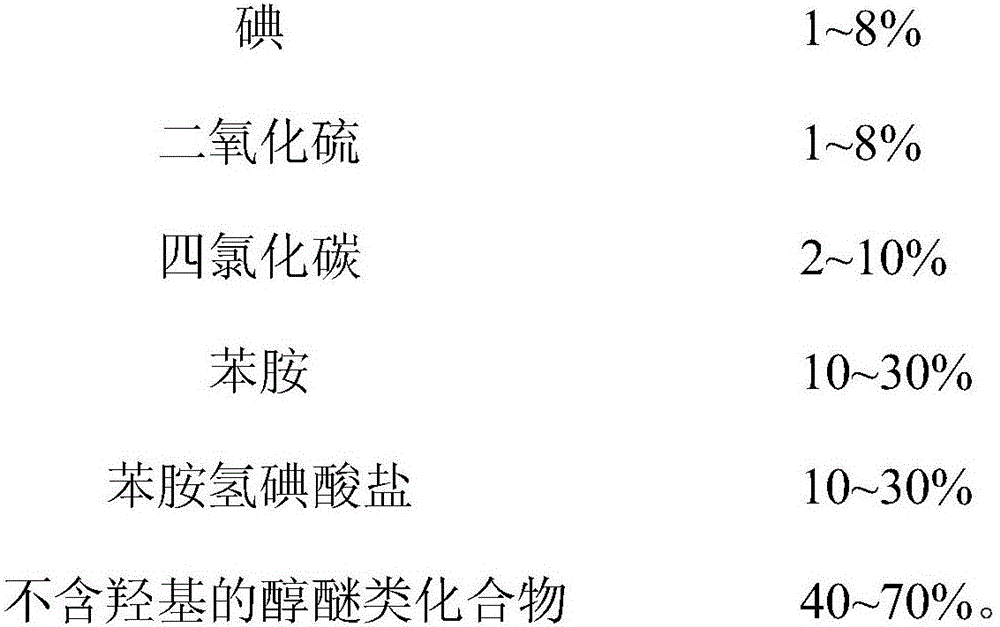

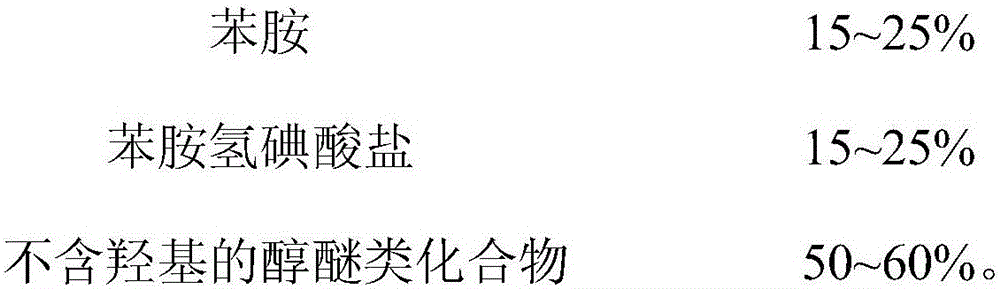

Method used

Image

Examples

Embodiment 1

[0029] At normal temperature, add 54wt% ethylene glycol dimethyl ether, 20wt% aniline and 1.5wt% iodine into the reaction kettle successively, and stir fully to form a mixed solution; bath, and slowly feed 1wt% sulfur dioxide gas, stir evenly, at this time the pH of the solution is 5.4; the temperature is raised to normal temperature, add 20wt% aniline hydroiodide and 3.5wt% carbon tetrachloride, stir until completely dissolved, Leave it for 24 hours to get the product.

Embodiment 2

[0031] At room temperature, successively add 70wt% propylene glycol dimethyl ether, 10wt% aniline and 3wt% iodine into the reaction kettle, and fully stir to form a mixed solution; then place the mixed solution in an ice bath with a temperature of 0-4°C, And slowly feed 2wt% sulfur dioxide gas, stir evenly, at this time the pH of the solution is 5.0; raise the temperature to normal temperature, add 10wt% aniline hydriodide and 5wt% carbon tetrachloride, stir until completely dissolved, place for 24h, that is get the product.

Embodiment 3

[0033] At room temperature, sequentially add 40wt% hexamethylene glycol dimethyl ether, 20wt% aniline and 8wt% iodine into the reaction kettle, and stir fully to form a mixed solution; then place the mixed solution in an ice bath with a temperature of 0-4°C and slowly feed 8wt% sulfur dioxide gas into the solution, stir evenly, at this time the pH of the solution is 4.0; raise the temperature to room temperature, add 20wt% aniline hydroiodide and 4wt% carbon tetrachloride, stir until completely dissolved, and place for 24h , that is, the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com