A kind of vanadium oxide anode buffer layer and its preparation method and application

An anode buffer layer and vanadium oxide technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of complex organic modification process, inapplicable preparation process, expensive equipment, etc., to improve energy conversion efficiency , good compatibility, excellent interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

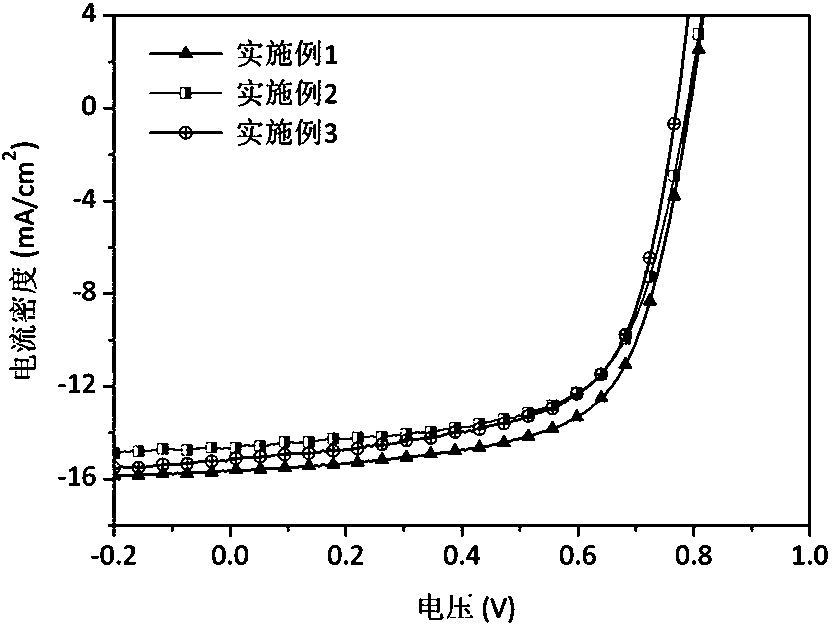

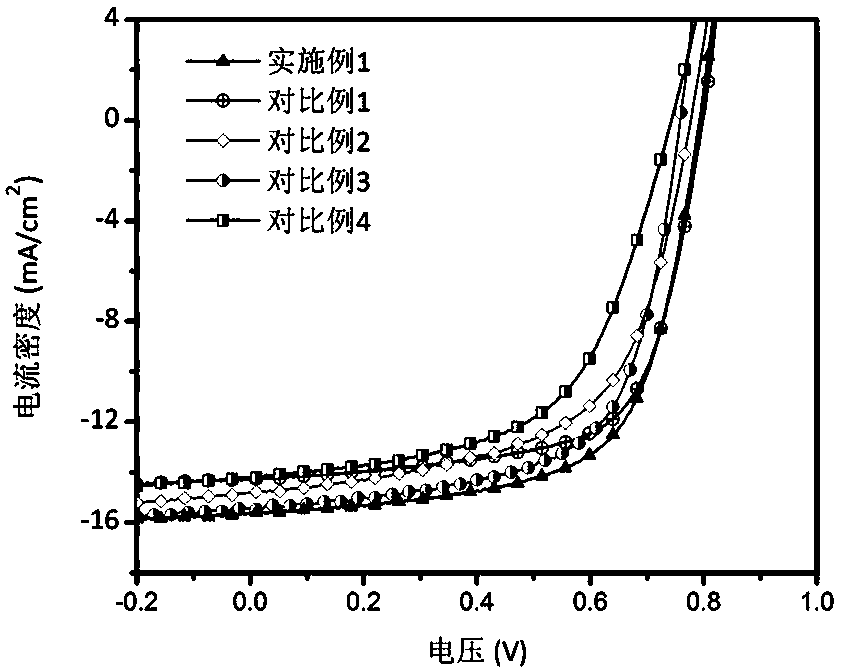

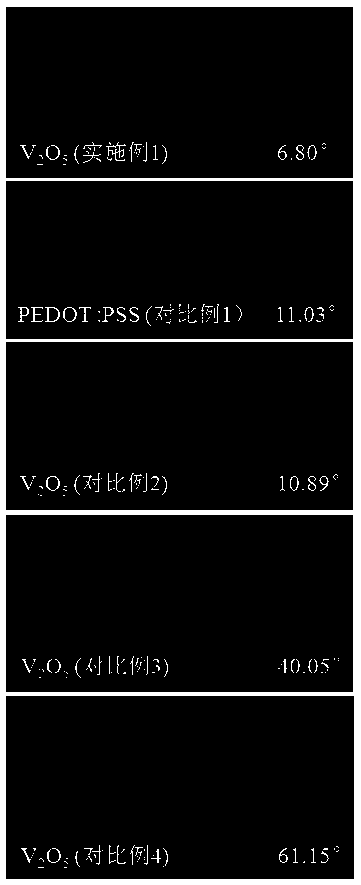

[0031] Prepare vanadium oxide film and use it as an anode buffer layer (or hole transport layer) to make organic polymer solar cells. Prepare a 1.0 mg / mL solution of vanadium acetylacetonate in isopropanol, sonicate for 8 minutes to dissolve it completely, and set aside. On the cleaned ITO conductive glass substrate, a layer of vanadium acetylacetonate thin film is prepared. Coating conditions: the spin coating speed is 2000 rpm, and the spin time is 40 seconds. The vanadium acetylacetonate thin film was annealed on a heating plate in air for 3 minutes, and the heating temperature was 150° C.

[0032] h 2 o 2 - UVO treatment of the film to obtain a vanadium oxide anode buffer layer. Treatment conditions: Coat a layer of 30vv% H on the film prepared above 2 o 2 The solution was processed at a rotation speed of 2000 rpm and a rotation time of 40 seconds. Then transfer to a UV ozone machine (power consumption: 0.5 KW), treat for 10 minutes, and cool naturally to room tempe...

Embodiment 2

[0035] Prepare a 1.5 mg / mL solution of vanadium acetylacetonate in isopropanol, sonicate for 10 minutes to dissolve it completely, and set aside. On the cleaned ITO conductive glass substrate, a layer of vanadium acetylacetonate thin film is coated. Coating conditions: the spin coating speed is 2000 rpm, and the spin time is 40 seconds. The vanadium acetylacetonate thin film was annealed on a heating plate in air for 3 minutes, and the heating temperature was 150° C.

[0036] h 2 o 2 -UVO treatment, treatment conditions: coat a layer of 30% H on the film prepared under the above conditions 2 o 2 The solution was processed at a rotation speed of 2000 rpm and a rotation time of 40 seconds. Then transfer to a UV ozone machine (power consumption: 0.5 KW), treat for 10 minutes, and naturally cool to room temperature to obtain a vanadium oxide anode buffer layer; coat a layer of PTB7- th:PC 71 BM (the mass ratio of the two is 1:1.5) photosensitive layer. Coating condition: P...

Embodiment 3

[0039] Prepare a 2.0 mg / mL solution of vanadium acetylacetonate in isopropanol, sonicate for 10 minutes to dissolve it completely, and set aside. On the cleaned ITO conductive glass substrate, a layer of vanadium acetylacetonate thin film is coated. Coating conditions: the spin coating speed is 2000 rpm, and the spin time is 40 seconds. The vanadium acetylacetonate thin film was annealed on a heating plate in air for 3 minutes, and the heating temperature was 150° C.

[0040] h 2 o 2 -UVO treatment, treatment conditions: coat a layer of 30% H on the film prepared under the above conditions 2 o 2 The solution was rotated at 2000 rpm for 40 seconds. Then transfer to an ultraviolet ozone machine (power consumption: 0.5 KW), treat for 10 minutes, and cool down to room temperature naturally to obtain a vanadium oxide anode buffer layer. Coating a layer of PTB7-th:PC with a thickness of about 80 nm on the ITO / vanadium oxide film 71 BM (the mass ratio of the two is 1:1.5) phot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com