Preparation method of nitrogen-doped graphene electrode material

A technology of nitrogen-doped graphene and electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unstable operation of electrodes for a long time, and achieve the effects of simple preparation process, good stability, and good output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

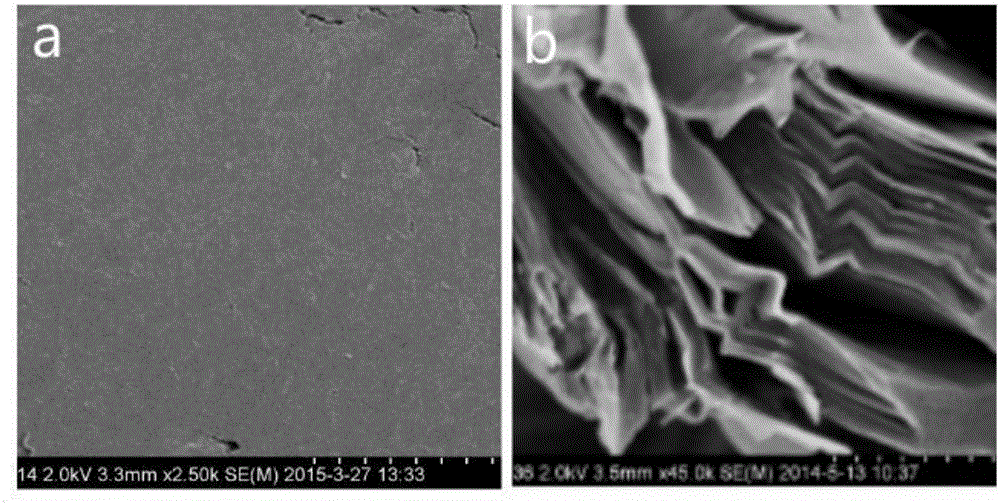

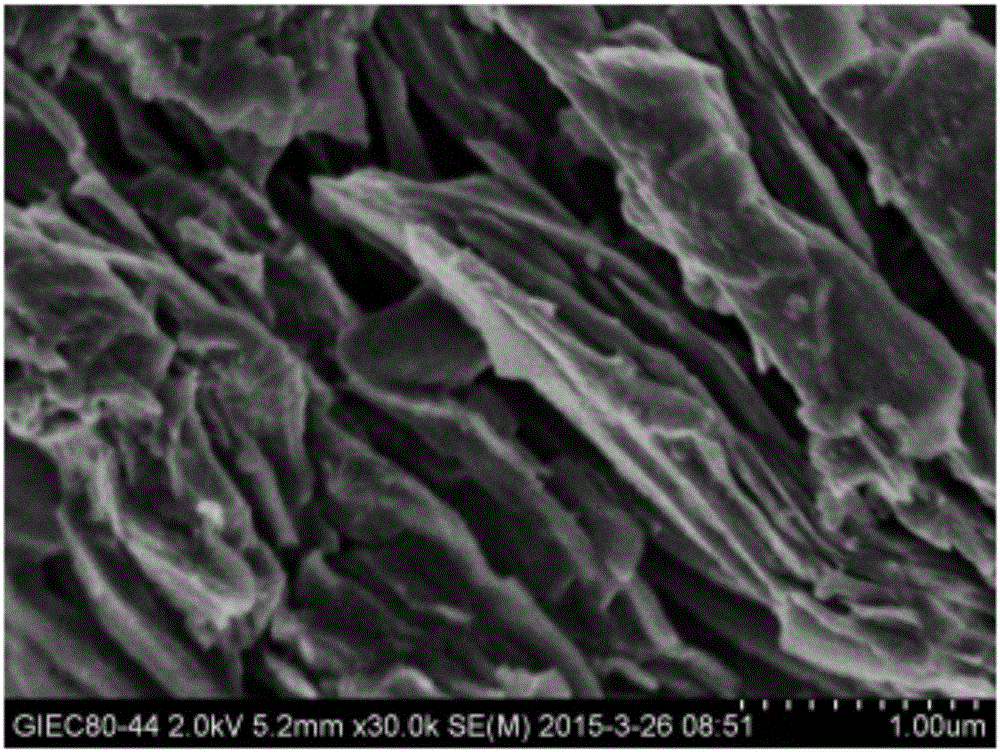

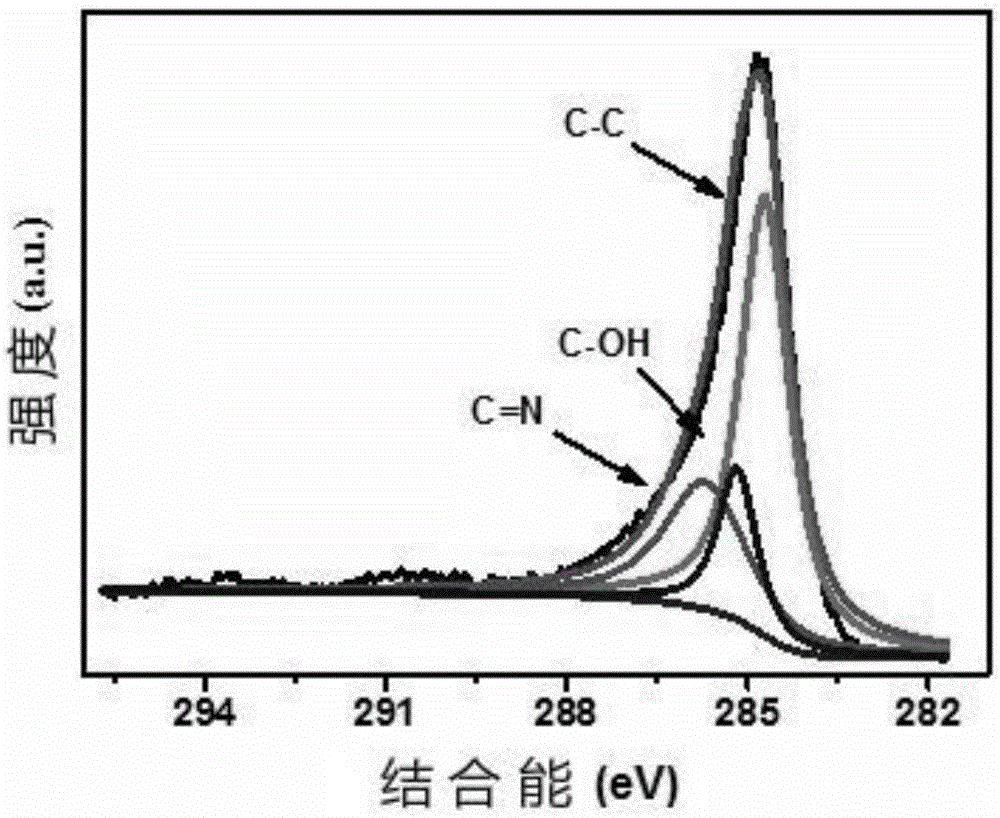

[0049]Use carbon paper (2*2*1cm) as the base, clean the carbon paper in 1.0 M HCl solution, soak for 5 minutes, remove impurities, and wash with deionized water; continue to wash with 1.0 M NaOH, rinse with deionized water . Next, the carbon paper was electrolyzed in water; two pieces of carbon paper were used as positive and negative electrodes respectively, and an alternating current of 15 V was applied between the positive and negative electrodes, and the electrolysis time was 8 minutes. Among them, the carbon paper electrode specification is 2*2*1cm. During the electrolysis process, the distance between the two electrodes is 6 cm, and the 2*2cm sides are facing each other. After electrolysis, the carbon paper was immersed in 10 mM dopamine hydrochloride buffer (pH 7.0) for self-polymerization reaction at room temperature for 30 minutes. The carbon paper obtained after electrolysis was taken out, dried, and calcined at 950° C. for 12 minutes under the protection of nitroge...

Embodiment 2

[0053] Use carbon paper (2*2*0.5cm) as the base, clean the carbon paper in 1.0 M HCl solution to remove impurities, soak for 5 minutes, wash with deionized water, continue to wash with 1.0 M NaOH solution, and deionize Wash with water. Next, the carbon paper was electrolyzed in water; two pieces of carbon paper were used as positive and negative electrodes respectively, and an alternating current of 12 V was applied between the positive and negative electrodes, and the electrolysis time was 10 minutes. Among them, the carbon paper electrode specification is 2*2*0.5cm. During the electrolysis process, the distance between the two electrodes is 5cm, and the 2*2cm sides are facing each other. After the electrolysis, the carbon paper was immersed in 10 mM dopamine hydrochloride buffer solution (pH 7.0) for self-polymerization reaction for 30 minutes. The carbon paper was taken out, dried, and calcined at 900° C. for 15 minutes under the protection of nitrogen to obtain a nitrogen...

Embodiment 3

[0057] With graphite plate (2*2*0.5cm) as the base, clean the carbon paper in 1.0 M HCl solution to remove impurities, soak in HCl solution for 5 minutes, wash with deionized water; continue to wash with 1.0 M NaOH solution , washed with deionized water; then, the graphite plate was electrolyzed in an aqueous solution. Two graphite plates are used as positive and negative electrodes respectively. An alternating current of 10 V was applied between the positive and negative electrodes, and the electrolysis time was 20 minutes. Among them, the carbon paper electrode specification is 2*2*0.5cm. During the electrolysis process, the distance between the two electrodes is 5cm, and the 2*2cm sides are facing each other. After electrolysis, the carbon paper was immersed in egg white solution (5 mL egg white / 100 mL water) for 30 minutes. The graphite plate was taken out, dried, and calcined at 850° C. for 20 minutes under the protection of nitrogen to obtain a nitrogen-doped graphene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com