High-rate high-safety soft package lithium-ion battery and preparation method thereof

A lithium-ion battery, high-safety technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problem of reducing the safety performance of lithium-ion batteries, not improving the lithium-ion conduction rate, not improving the lithium-ion transmission rate, etc. problems, to achieve the effect of reducing thermal runaway, preventing local overheating, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

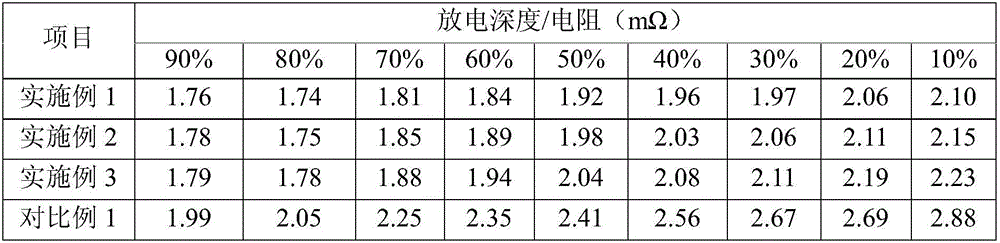

Embodiment 1

[0026] 1) Weigh 20g of polyvinylidene fluoride and add it to 200g of N-methylpyrrolidone, stir evenly, add 55g of alumina and 25g of melamine cyanurate, and then disperse for 2 hours to obtain spraying liquid A; at the same time, weigh 30g of polyvinylidene fluoride Add vinyl fluoride to 200g of N-methylpyrrolidone, disperse evenly, then add 70g of lithium hexafluoroaluminate, and disperse for another 2 hours to obtain spray liquid B;

[0027] 2) Then spray the spraying liquid A on one side of the PP diaphragm with a thickness of 20 μm (the coating thickness is 3 μm) by a spraying machine. After drying, the diaphragm C is obtained, and then spray the spraying liquid B on the other side of the diaphragm C ( The coating thickness is 3 μm), and the composite separator D is obtained after drying;

[0028] 3) After that, the lithium iron phosphate positive electrode slurry (mass ratio: lithium iron phosphate: conductive agent SP: polyvinylidene fluoride: N-methylpyrrolidone = 93:3:...

Embodiment 2

[0031] 1) Weigh 10g of sodium carboxymethylcellulose and add it to 200g of N-methylpyrrolidone, stir evenly, add 60g of aluminum oxide and 30g of pentaerythritol melamine phosphate, and then disperse for 2 hours to obtain spraying liquid A; at the same time, weigh 20g of carboxymethylcellulose Add methyl cellulose sodium to 200g of N-methylpyrrolidone, after dispersing evenly, add 80g of lithium hexafluoroaluminate, and disperse for another 2h to obtain spray solution B;

[0032] 2) Then spray the spraying liquid A on one side of the PP diaphragm with a thickness of 20 μm (the coating thickness is 2 μm) by a spraying machine. After drying, the diaphragm C is obtained, and then spray the spraying liquid B on the other side of the diaphragm C ( The coating thickness is 2 μm), and the composite separator D is obtained after drying;

[0033] 3) After that, the lithium iron phosphate positive electrode slurry (mass ratio: lithium iron phosphate: conductive agent SP: polyvinylidene ...

Embodiment 3

[0036] 1) Weigh 30g of polyacrylic acid and add it to 200g of N-methylpyrrolidone, stir evenly, add 50g of alumina and 20g of ammonium polyphosphate, and then disperse for 2 hours to obtain spray liquid A; at the same time, weigh 40g of polyacrylic acid and add it to 200g In the N-methylpyrrolidone, after uniform dispersion, add 60g of lithium hexafluorotitanate, and then disperse for 2h to obtain spraying liquid B;

[0037] 2) After that, spray the spraying liquid A on one side of the PP diaphragm with a thickness of 20 μm (the coating thickness is 4 μm) by a spraying machine. After drying, the diaphragm C is obtained, and then spray the spraying liquid B on the other side of the diaphragm C ( The coating thickness is 4 μm), and the composite separator D is obtained after drying;

[0038]3) After that, the lithium iron phosphate positive electrode slurry (mass ratio: lithium iron phosphate: conductive agent SP: polyvinylidene fluoride: N-methylpyrrolidone = 93:3:4:150) is coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com