Lithium ion battery electrolyte and lithium ion battery containing same

A lithium-ion battery and electrolyte technology, which is applied in the field of lithium-ion battery electrolyte and lithium-ion batteries containing the electrolyte, can solve problems such as loss of stability, reduced battery capacity and cycle life, and reduced battery safety. Improve cycle performance and safety, prevent excessive insertion of negative electrodes, and slow down the effect of battery inflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

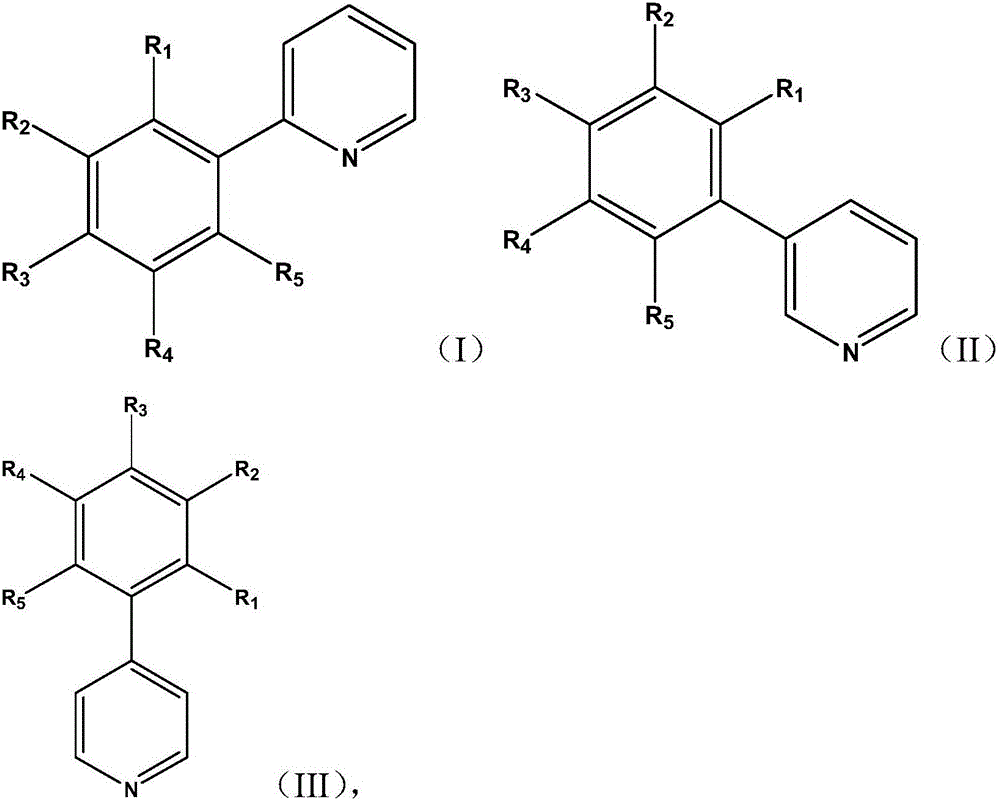

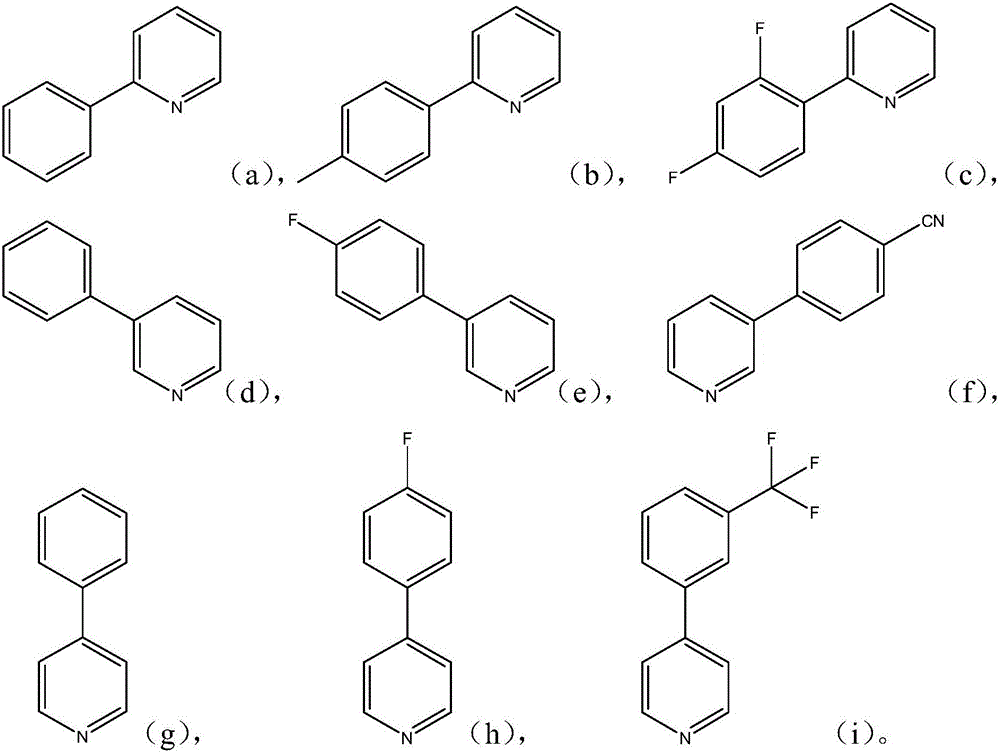

Method used

Image

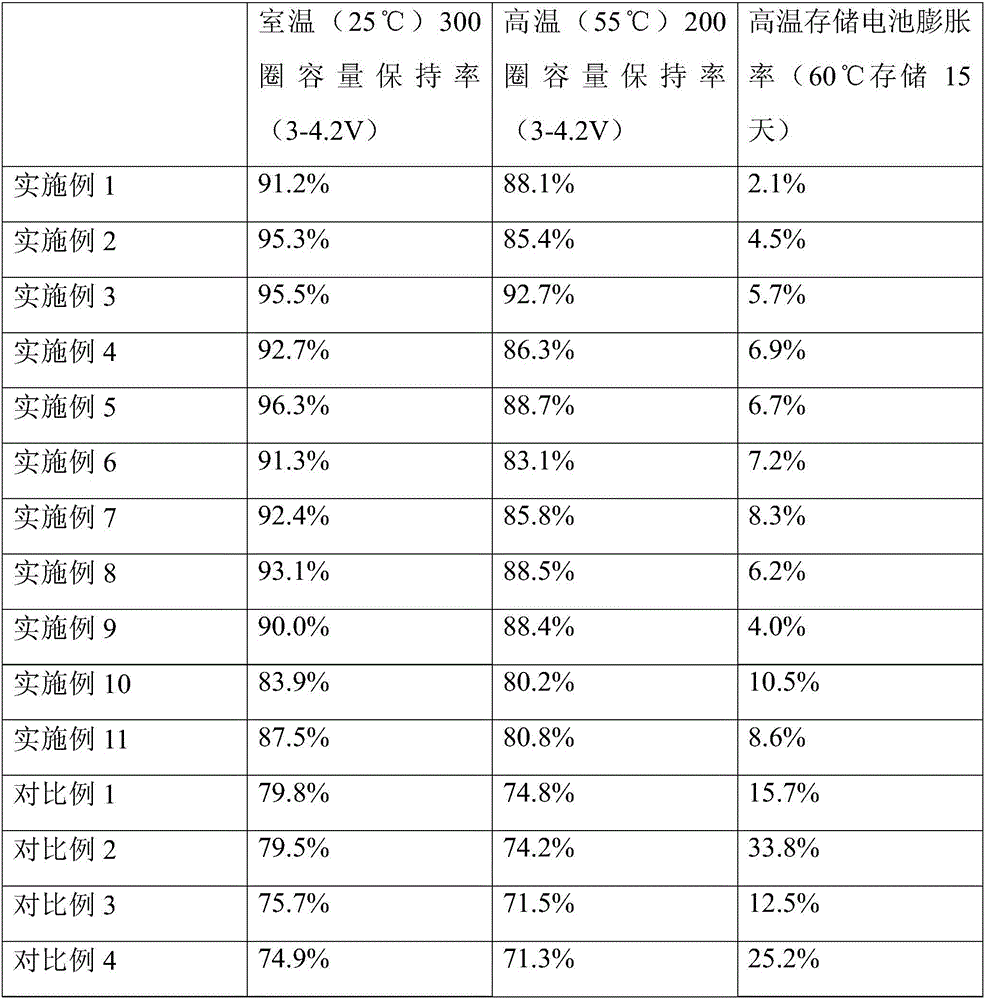

Examples

Embodiment 1

[0027] (1) Preparation of electrolyte

[0028] In a glove box filled with argon (moisture content < 0.1ppm, oxygen content < 0.1ppm), mix ethylene carbonate and diethyl carbonate in a mass ratio of 1:2 and stir continuously, slowly add to the mixed solvent Add 1.0 mol / L lithium hexafluorophosphate, then add 2.0% vinylene carbonate, 1.0% succinonitrile, and 1.0% 2-phenylpyridine, and stir until completely dissolved to obtain the electrolyte solution of this example .

[0029] (2) Preparation of lithium ion battery:

[0030] LiCoO 2 It is used as the positive electrode active material, and graphite is used as the negative electrode active material. After adding conductive agent, binder and solvent, they are fully stirred and mixed evenly. The positive and negative pole pieces and the polypropylene separator are wound into a square lithium-ion battery. After baking at 85°C for 48 hours, it was transferred to a glove box for liquid injection, and after sealing, it was aged, fo...

Embodiment 2

[0032] (1) Preparation of electrolyte

[0033] In a glove box filled with argon (moisture content < 0.1ppm, oxygen content < 0.1ppm), mix ethylene carbonate and diethyl carbonate in a mass ratio of 1:3 and stir continuously, slowly add to the mixed solvent Add 1.2mol / L lithium hexafluorophosphate, then add 3.0% fluoroethylene carbonate, 0.5% ethylene carbonate, and 2.0% 2-(4-methylphenyl)pyridine, and stir until completely dissolved , to obtain the electrolyte solution of this embodiment.

[0034] (2) Preparation of lithium ion battery

[0035] Take LiNi 0.8 co 0.15 al 0.05 o 2 It is used as the positive electrode active material, and graphite is used as the negative electrode active material. After adding conductive agent, binder and solvent, they are fully stirred and mixed evenly. The positive and negative pole pieces and the polypropylene separator are wound into a square lithium-ion battery. After baking at 85°C for 48 hours, it was transferred to a glove box for l...

Embodiment 3

[0037] (1) Preparation of electrolyte

[0038] In a glove box filled with argon (moisture content < 0.1ppm, oxygen content < 0.1ppm), mix ethylene carbonate and ethyl methyl carbonate in a mass ratio of 1:1 and stir continuously, slowly add to the mixed solvent Add 1.0mol / L lithium hexafluorophosphate, then add 1.5% 1,3-propane sultone, 2.0% ethylene carbonate, 3.0% 2-(2,4-difluorophenyl) Pyridine was stirred until completely dissolved to obtain the electrolyte solution of this embodiment.

[0039] (2) Preparation of lithium ion battery

[0040] Take LiNi0.5 mn 0.3 co 0.2 o 2 It is used as the positive electrode active material, and graphite is used as the negative electrode active material. After adding conductive agent, binder and solvent, they are fully stirred and mixed evenly. The positive and negative pole pieces and the polypropylene separator are wound into a square lithium-ion battery. After baking at 85°C for 48 hours, it was transferred to a glove box for liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com