An Interleaved Parallel Buck Converter for High Speed Motor Control

A technology of high-speed motors and converters, applied in the direction of AC motor control, control system, and regulation of electrical variables, etc., can solve the problems of not providing interleaved parallel Buck converter modulation method, unable to meet the needs of inductive loads, and unable to solve modulation problems, etc. Achieve the effect of ensuring power modulation requirements, reducing loss, and reducing conversion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

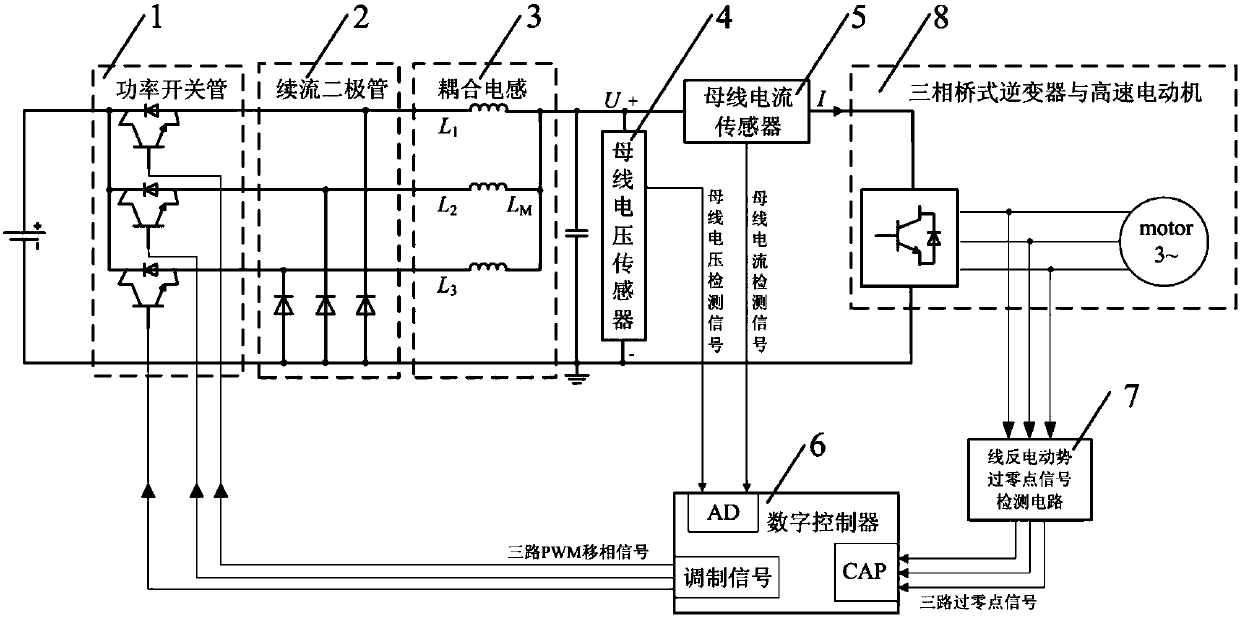

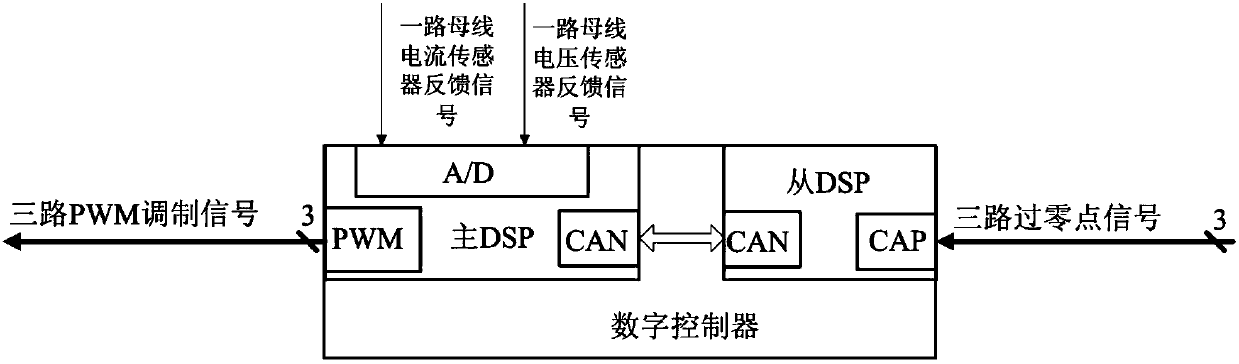

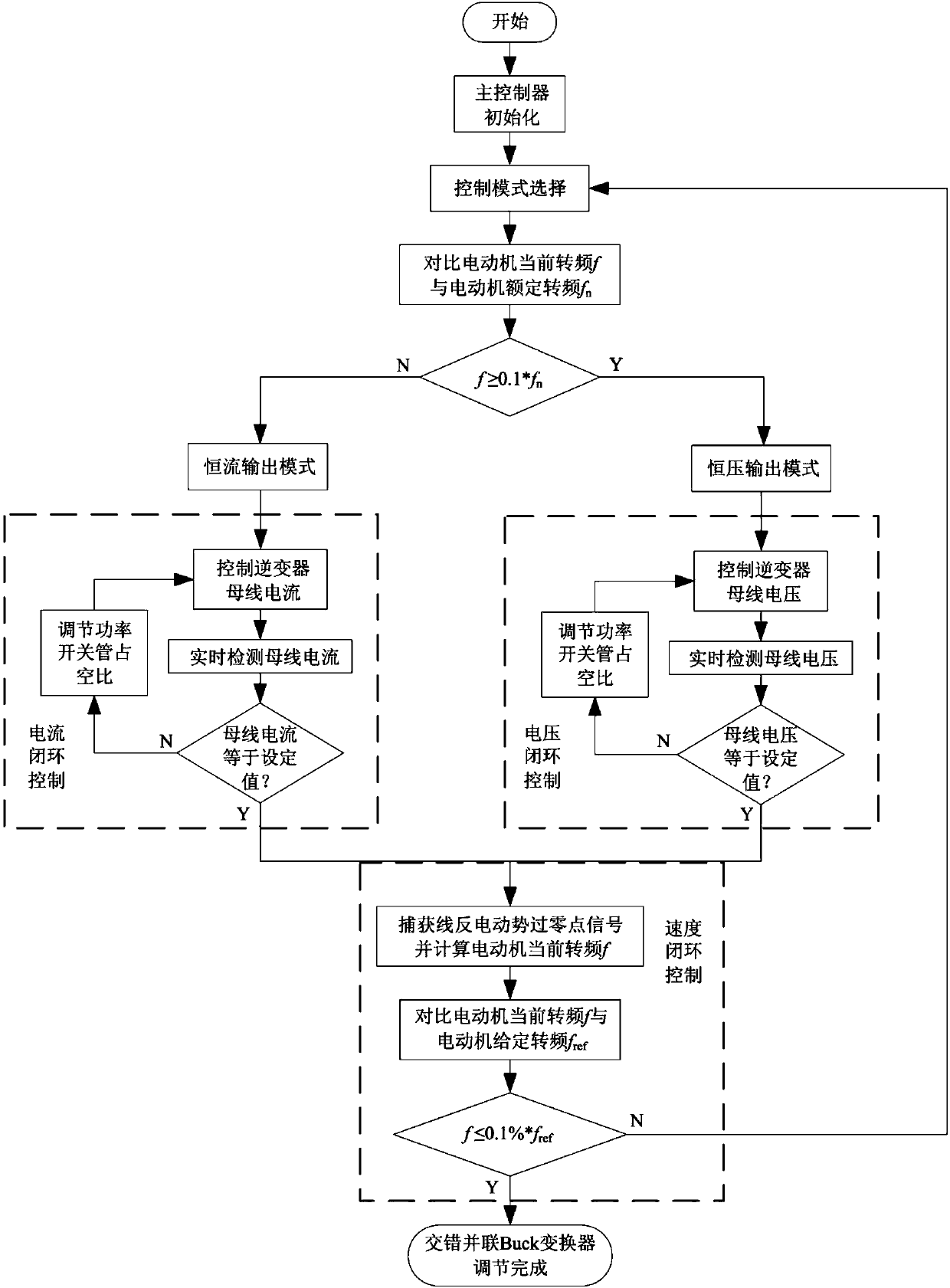

[0027] Such as figure 1 Shown is an interleaved parallel Buck converter for high-speed motor control system, including power switch tube 1, freewheeling diode 2, three-way coupling inductor 3, bus voltage sensor 4, bus current sensor 5, and three-phase bridge inverter And high-speed motor 8, line counter electromotive force zero-crossing signal detection circuit 7, digital controller 6. After the DC power is phase-shifted and chopped by the power switch tube 1, the corresponding inductor L in the three-way coupled inductor 3 is respectively 1 , L 2 or L 3 Filtering, and the freewheeling diode 2 plays a freewheeling role when the power switch tube 1 is turned off. Three-way coupled inductor 3 common point tap L M The output chopping voltage is filtered by a capacitor to output a DC voltage U, U is detected by a bus voltage sensor, U is connected in series with a bus current sensor, and then input to a three-phase bridge inverter and a high-speed motor 8 . The voltage analo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com