D-galactose addition feed for constructing senile dementia animal model and preparation method thereof

An animal model, galactose technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

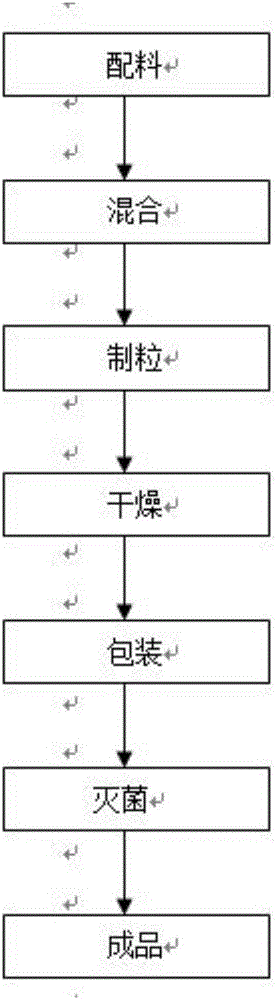

[0047] Its preparation method comprises the following steps:

[0048] 1), raw material pretreatment,

[0049] First, weigh 1% to 5% of corn oil and 2% to 6% of anhydrous milk fat, heat the corn oil and anhydrous milk fat to 70-80°C to melt, add 3% to 10% of the total weight of raw materials in water, and stir well , in a semi-fluid state; stand-by;

[0050] Weigh raw materials according to the proportion: casein, corn starch, maltodextrin, sucrose, cellulose, DL-methionine, D-galactose, complex minerals, calcium carbonate, multivitamins and choline bitartrate;

[0051] 2), prepare the mixture,

[0052] Mix the weighed raw materials, stir evenly, add the above semi-fluid fat, and continue mixing for 2 to 4 minutes;

[0053] 3), prepare the product,

[0054] At 20-30°C, feed pellets with a diameter of 10mm and a length of 15-20mm are produced by a ring die pellet machine; at 20-25°C, the feed pellets are dehumidified and dried for 24-36 hours through a dehumidifier, and fina...

specific Embodiment 1

[0058] 1), raw material pretreatment,

[0059] First, weigh the materials in the raw materials: 1% corn oil, 2% anhydrous milk fat, heat the corn oil and anhydrous milk fat to 70°C to melt, add the total weight of the raw materials to the heated and melted corn oil and anhydrous milk fat mixture 3% water, stir evenly to form a semi-fluid fat material; set aside;

[0060] Weigh other materials in raw materials according to the proportion: 20% casein, 15% corn starch, 10% maltodextrin, 20% sucrose, 5% cellulose, 0.1% DL-methionine, 0.02% D-galactose, compound mineral Substance 0.5%, calcium carbonate 0.1%, multivitamin 0.5% and choline bitartrate 0.2%;

[0061] 2), prepare the mixture,

[0062] Mix the weighed raw materials, stir evenly, add the above semi-fluid fat, and continue mixing for 2 to 4 minutes;

[0063] 3), prepare the product,

[0064] At 20-30°C, feed pellets with a diameter of 10mm and a length of 15-20mm are produced by a ring die pellet machine; at 20-25°C, ...

specific Embodiment 2

[0068] 1), raw material pretreatment,

[0069] First, weigh the materials in the raw materials: 3% corn oil, 4% anhydrous milk fat, heat the corn oil and anhydrous milk fat to 75°C to melt, add the total weight of the raw materials to the heated and melted corn oil and anhydrous milk fat mixture 6.5% water, stir evenly to form a semi-fluid fat; set aside;

[0070] Weigh other materials in raw materials according to the proportion: 25% casein, 22.5% corn starch, 15% maltodextrin, 25% sucrose, 7.5% cellulose, 0.3% DL-methionine, 0.06% D-galactose, compound mineral Substance 2%, calcium carbonate 0.3%, multivitamin 1.75% and choline bitartrate 0.6%;

[0071] 2), prepare the mixture,

[0072] Mix the weighed raw materials, stir evenly, add the above semi-fluid fat, and continue mixing for 2 to 4 minutes;

[0073] 3), prepare the product,

[0074] At 20-30°C, feed pellets with a diameter of 10mm and a length of 15-20mm are produced by a ring die pellet machine; at 20-25°C, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com