Retort char, gas, oil, liquid, heat and fertilizer co-production system and process by biomass waste recycling

A biomass and dry distillation technology, used in biofuels, petroleum industry, special forms of dry distillation, etc., can solve the problems of waste of resources, low utilization rate of equipment, low utilization rate of heat energy, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

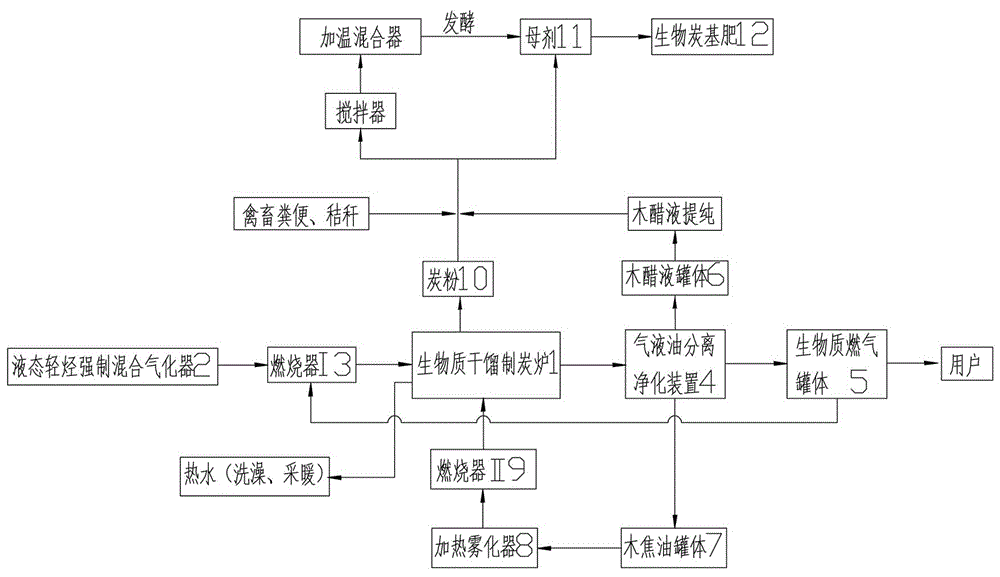

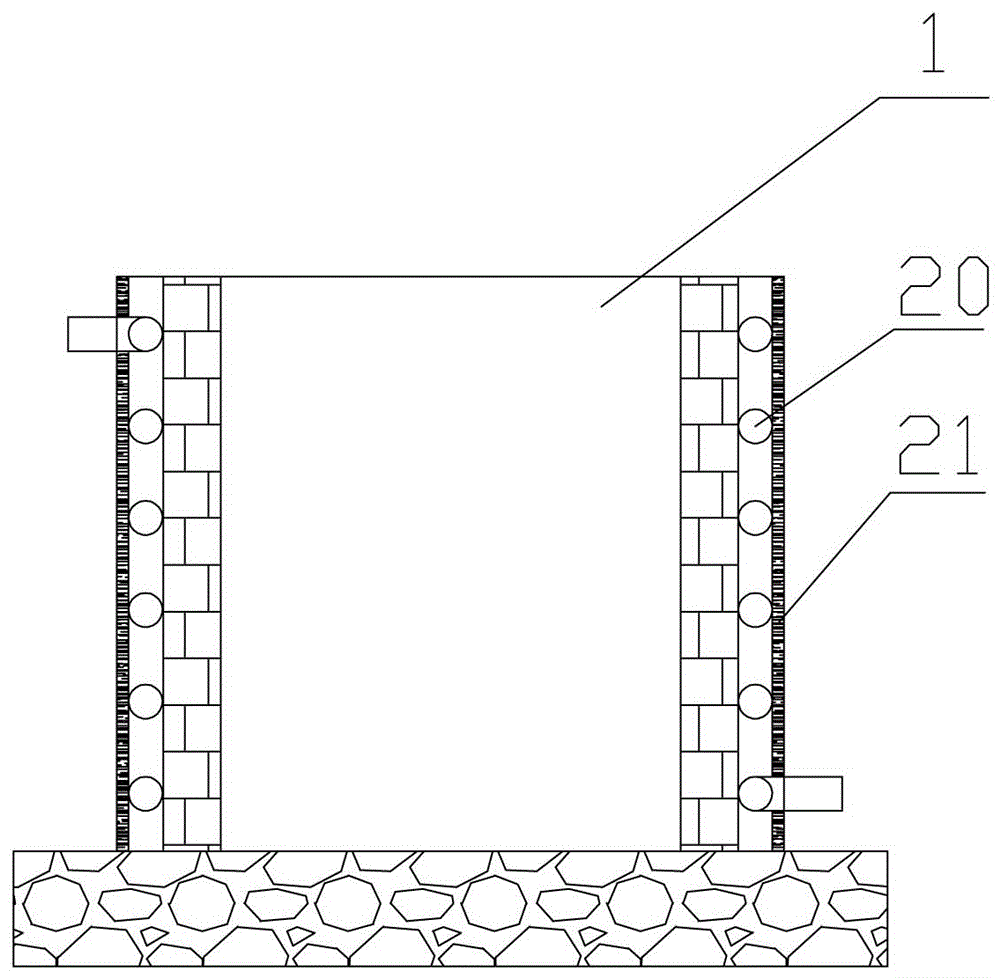

[0022] like figure 1 As shown in the figure, a biomass waste recycling system for cogeneration of charcoal, gas, oil, liquid, heat and fertilizer, the passing burner I3 of the liquid light hydrocarbon forced mixed gasifier 2 communicates with the combustion chamber of the biomass carbonization furnace 1, and the biomass The gas outlet of the dry distillation charcoal furnace 1 is connected to the gas-liquid-oil separation and purification device 4, and the products obtained by the gas-liquid-oil separation and purification device 4 through process treatment are respectively corresponding to the biomass gas tank 5, wood vinegar liquid tank 6 and wood The tar tank 7 is connected, and the outlet of the wood tar tank 7 produces atomized tar through the heating atomizer 8, and then communicates with the combustion chamber of the biomass carbonization charcoal furnace 1 through the burner II 9; the biomass gas tank 5 is connected to the burner I3 through the control valve; the solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com