Preparation method of dried hylocereus undulatus britt

A technology of dragon fruit and dried fruit, which is applied in the field of preparation of dried dragon fruit, can solve the problems of damage to the nutritional components of the pulp, sour taste, long time, etc., and achieve the effect of white color, strong fruit fragrance and uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Peel the pitaya fruit, cut the pitaya pulp into pieces, break it into a slurry, and obtain the pitaya pulp without destroying the black seeds in the pulp;

[0026] (2) Add 0.4g of powdered sugar to 100g of dragon fruit slurry obtained in step (1), stir evenly at a speed of 35r / min, vacuum concentrate at a vacuum degree of 90kPa and a temperature of 50°C until the water content is 45%, and obtain Pitaya fruit concentrate;

[0027] (3) Pour the dragon fruit concentrate obtained in step (2) into a spherical mold (2cm in diameter), freeze for the first time at -6°C for 36 hours, demould, and then freeze for the second time at -6°C 2.5h, and finally at a vacuum degree of 40MPa and a temperature of -30°C, vacuum freeze-drying for 48h to obtain dried dragon fruit.

Embodiment 2

[0029] (1) Peel the pitaya fruit, cut the pitaya pulp into pieces, break it into a slurry, and obtain the pitaya pulp without destroying the black seeds in the pulp;

[0030] (2) Add 0.4g of powdered sugar to 100g of dragon fruit slurry obtained in step (1), stir evenly at a speed of 40r / min, vacuum concentrate at a vacuum degree of 85kPa and a temperature of 45°C until the water content is 30%, and obtain pitaya fruit concentrate;

[0031] (3) Pour the dragon fruit concentrate obtained in step (2) into a spherical mold (1.8cm in diameter), freeze for the first time at -10°C for 24 hours, demould, and then freeze for the second time at -10°C Freeze for 2 hours, and finally vacuum freeze-dry for 72 hours at a vacuum degree of 30 MPa and a temperature of -10° C. to obtain dried dragon fruit.

Embodiment 3

[0033] (1) Peel the pitaya fruit, cut the pitaya pulp into pieces, break it into a slurry, and obtain the pitaya pulp without destroying the black seeds in the pulp;

[0034] (2) Add 0.3g of powdered sugar to 100g of dragon fruit slurry obtained in step (1), stir evenly at a speed of 35r / min, vacuum concentrate at a vacuum degree of 90kPa and a temperature of 50°C until the water content is 45%, and obtain pitaya fruit concentrate;

[0035] (3) Pour the dragon fruit concentrate obtained in step (2) into a spherical mold (2cm in diameter), freeze for the first time at -6°C for 36 hours, demould, and then freeze for the second time at -6°C 2.5h, and finally at a vacuum degree of 40MPa and a temperature of -30°C, vacuum freeze-drying for 48h to obtain dried dragon fruit.

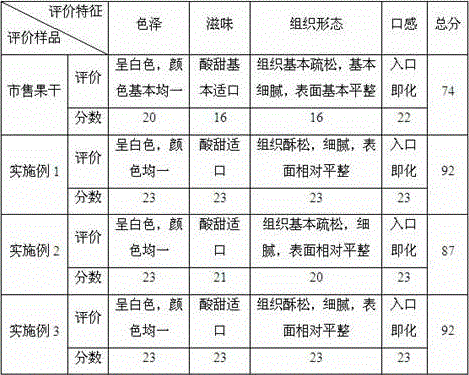

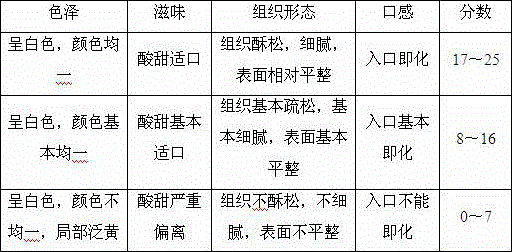

[0036] According to Table 1, the characteristics of four aspects of color, taste, texture and mouthfeel of the dried dragon fruit obtained in Examples 1 to 3 and commercially available dried dragon fruit are c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com