Tissue restoration fiber membrane, production method and application thereof, and tissue restoration product

A tissue repair and fibrous membrane technology, applied in tissue regeneration, textile and papermaking, fabric surface trimming, etc., can solve the problem that the performance of repairing fibrous membrane is not ideal, prone to foreign body sensation and pain, cell growth or slow growth, etc. The problem is that it is easy to achieve product standards, facilitate cell adhesion, and achieve the effect of tissue regeneration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] As a preferred preparation method of the fiber membrane for tissue repair of the present invention, it specifically includes the following steps:

[0059] (1) dissolving the fiber silk material in a solvent to obtain a fiber silk material solution;

[0060] (2) Load the fiber filament material solution obtained in step (1) into an electrospinning syringe, perform electrospinning, and receive the fiber filament into a film-like structure to obtain a fiber membrane;

[0061] (3) Four sides of the fibrous membrane prepared in step (2) are fixed, and then vacuum-dried and shaped at 30-60° C. with a vacuum degree of -0.06 to -0.12 MPa to obtain a fibrous membrane for tissue repair.

[0062] In the above step (3), the setting is carried out at 30-60°C, preferably at 35-55°C.

[0063] And before the setting in step (3), the fibrous membrane is soaked with a solvent different from that in step (1), provided that the fibrous membrane is not completely swollen. Wherein, "comple...

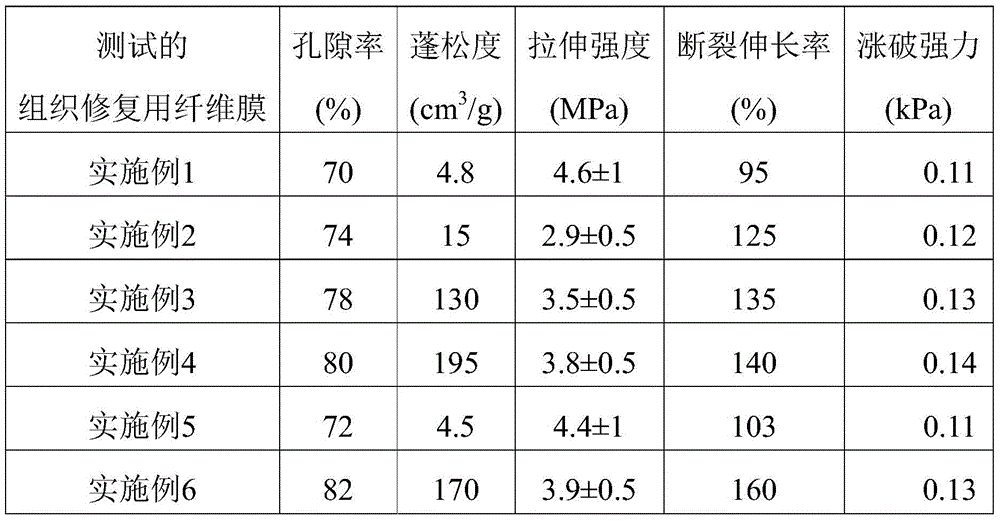

Embodiment 1

[0076] (1) Dissolve PLLA in hexafluoroisopropanol to form a 10.5 g / dL solution.

[0077](2) the solution that obtains in step (1) is contained in the syringe that is connected with high-pressure needle, the receiving distance of adjustment receiving device is 26cm, and the speed that regulation micro-injection pump advances PLLA is 6ml / h, then regulates positive high pressure as 25KV, the negative pressure is 0kv, the rotating roller is used as the receiving device, and the rotation speed is 100rpm, and then the electrospinning is carried out for 6h. After the electrospinning is completed, the membrane material is removed from the roller, and then vacuum-dried to remove the solvent to obtain a fiber membrane.

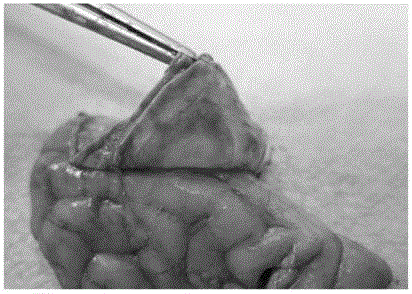

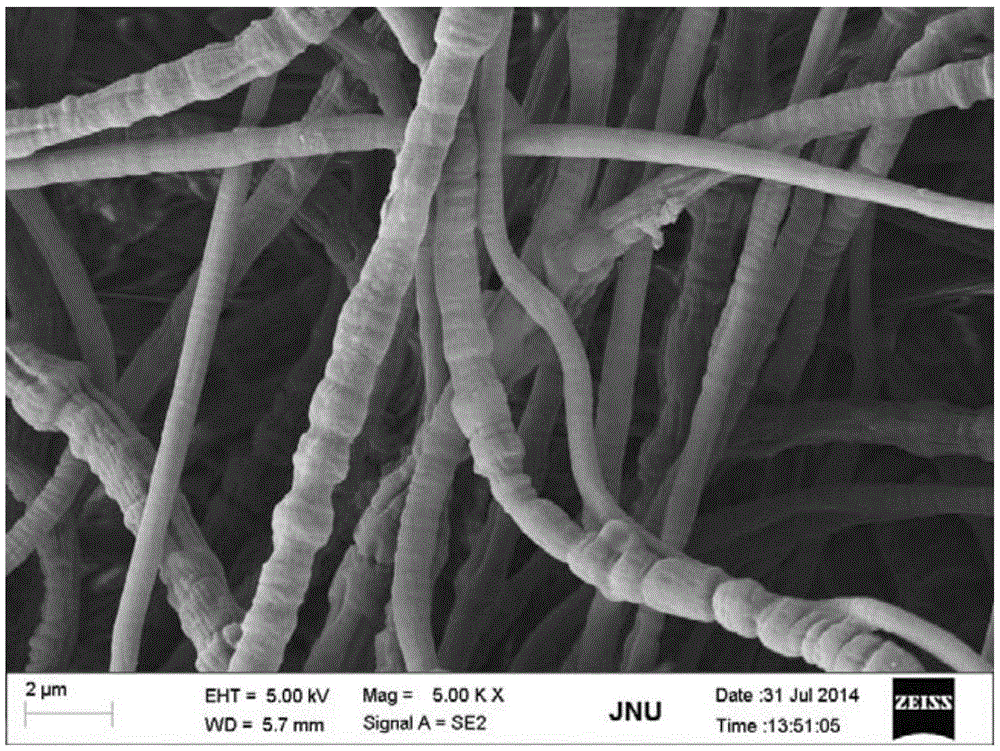

[0078] (3) Fix the four sides of the membrane material prepared in step (2), and set it at a temperature of 55°C and a vacuum of -0.1MPa for 72 hours to prepare a fiber membrane for tissue repair. The fibers in the fiber membrane for tissue repair The filament has a ri...

Embodiment 2

[0081] (1) Dissolve PLLA in hexafluoroisopropanol to form a 11.5 g / dL solution.

[0082] (2) the solution that obtains in step (1) is contained in the syringe that is connected with high-pressure needle, the receiving distance of adjustment receiving device is 27cm, and the speed that adjustment micro-injection pump advances PLLA is 6.3ml / h, then adjusts positive high pressure It is 24KV, the negative pressure is 0kv, the rotating roller is used as the receiving device, and the rotating speed is 100rpm, and then the electrospinning is carried out for 7h to obtain the fiber film, and then the solvent is removed by vacuum drying for later use.

[0083] (3) Fix the four sides of the film prepared in step (2), infiltrate it with alcohol with a volume concentration of 95% for 5 minutes, and then set it at a temperature of 50°C and a vacuum of -0.098MPa for 48 hours to prepare a tissue repair tissue. Fibrous membrane, the fibrous filaments in the tissue repairing fibrous membrane ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Loft | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com