Preparation method of hollow fiber organic gas separation membrane

A technology for organic gas and separation membranes, which is applied in separation methods, semipermeable membrane separation, and dispersed particle separation, etc. It can solve the problem that the functional layer is only attached to the outer surface of the basement membrane, the surface of the basement membrane is detached from swelling, and internal pressure operation cannot be realized, etc. problems, to achieve the effect of expanding application and applicable conditions, large membrane flux, and good separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

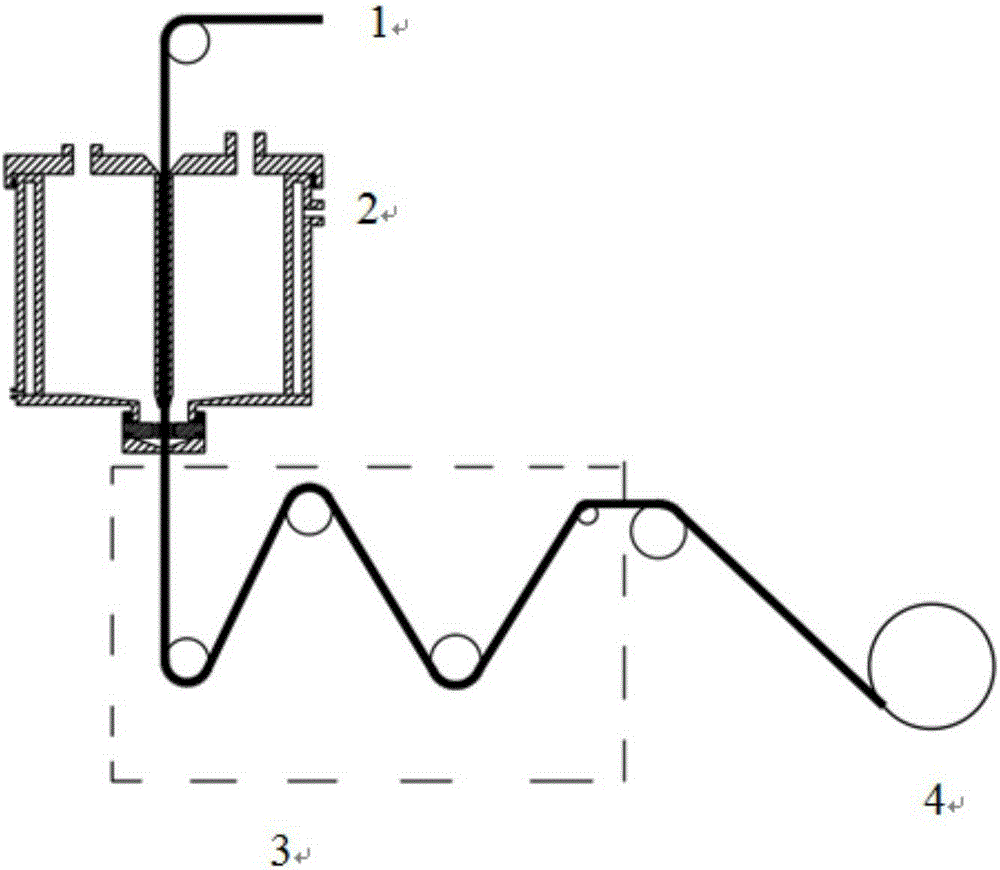

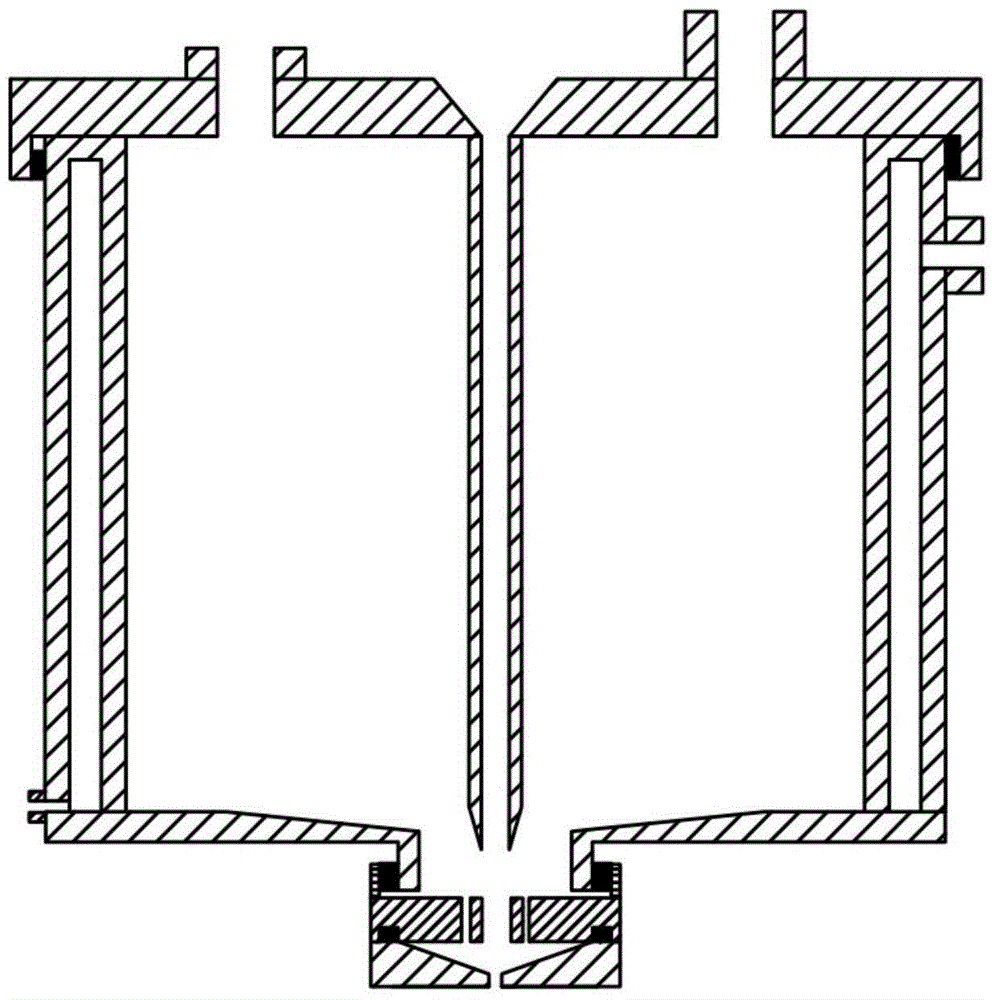

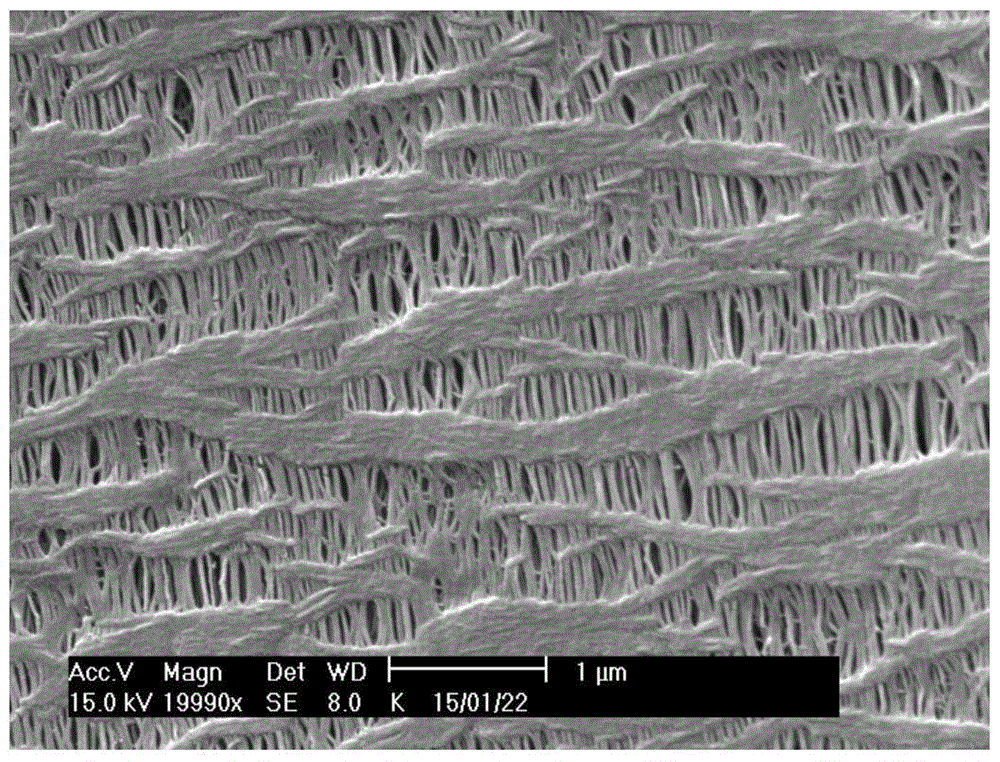

[0041] Such as Figure 1-2 Shown, a kind of preparation method of hollow fiber organic gas separation membrane comprises the following steps:

[0042] (1) Preparation of casting solution: Add polydimethylsiloxane (PDMS) and ethyl orthosilicate to the organic solvent n-hexane or n-heptane, stir for 24 hours, and mix well to form a mixed solution; then add A certain amount of dibutyltin dilaurate as a catalyst is stirred and mixed evenly to form a casting solution.

[0043] (2) Basement membrane treatment: The polymer hollow fiber membrane prepared by the melt stretching method is selected as the basement membrane, and it is cleaned with ethanol or n-hexane to prevent other additives or solid particles remaining in the membrane pores from affecting the filling of the functional layer.

[0044] (3) Filling film preparation: the base film 1 is pulled through the scraping head 2 at a certain speed, and the scraping head 2 scrapes the casting liquid from the outside of the base fil...

Embodiment 1

[0047] (1) Preparation of casting solution: Add polydimethylsiloxane and ethyl orthosilicate to n-hexane, stir for 24 hours, and mix well to form a mixed solution. Polydimethylsiloxane and ethyl orthosilicate The mass fractions in the mixed solution are 40% and 8%, respectively. Then add dibutyltin dilaurate as a catalyst in an amount of 0.02% by mass to the above solution, stir to dissolve it completely, and prepare a casting solution.

[0048] (2) Basement membrane treatment: select the polyethylene hollow fiber membrane that wall thickness is 30 microns, porosity 50%, average aperture is 200 nanometers melt stretching method preparations as basement membrane, soak and clean basement membrane with normal hexane, Avoid other additives or solid particles remaining in the membrane pores to affect the filling of the functional layer.

[0049] (3) Filling film preparation: such as figure 1 As shown, the base film is dragged through the scraping head at a speed of 0.2m / min, and ...

Embodiment 2

[0053] (1) Preparation of casting solution: Add polydimethylsiloxane and ethyl orthosilicate to n-hexane solution, stir for 24 hours, and mix well to form a mixed solution. Polydimethylsiloxane and ethyl orthosilicate The mass fractions of esters in the mixed solution were 2% and 0.1%, respectively. Then, adding 0.001% of the catalyst dibutyltin dilaurate into the above solution and stirring it to completely dissolve it to prepare a casting solution.

[0054] (2) basement membrane treatment: select the polypropylene hollow fiber membrane that wall thickness is 50 microns, porosity 20%, and average aperture is 100 nanometers melt stretching method preparations as basement membrane, suitable for n-hexane to soak and clean the basement membrane, Avoid other additives or solid particles remaining in the membrane pores to affect the filling of the functional layer.

[0055] (3) Filling film preparation: such as figure 1 As shown, the base film is pulled through the scraping head ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com