Method for enhancing catalytic denitrification activity of material by electron-beam irradiation modification and application thereof

A technology of electron beam irradiation and modification, which is applied in chemical instruments and methods, catalyst activation/preparation, separation methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

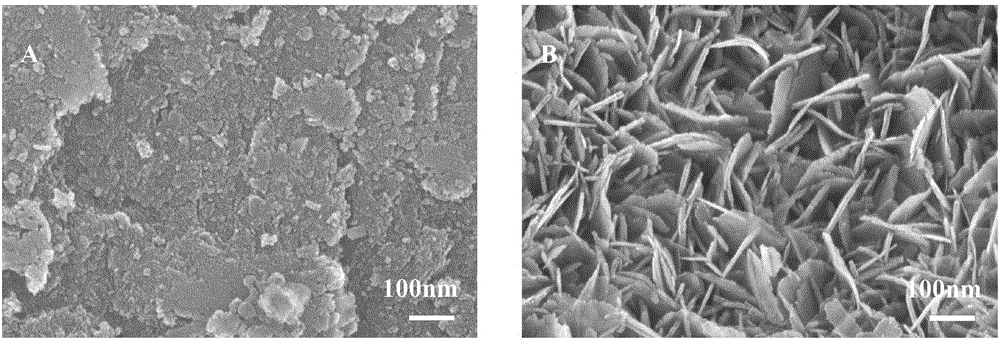

Image

Examples

Embodiment 1

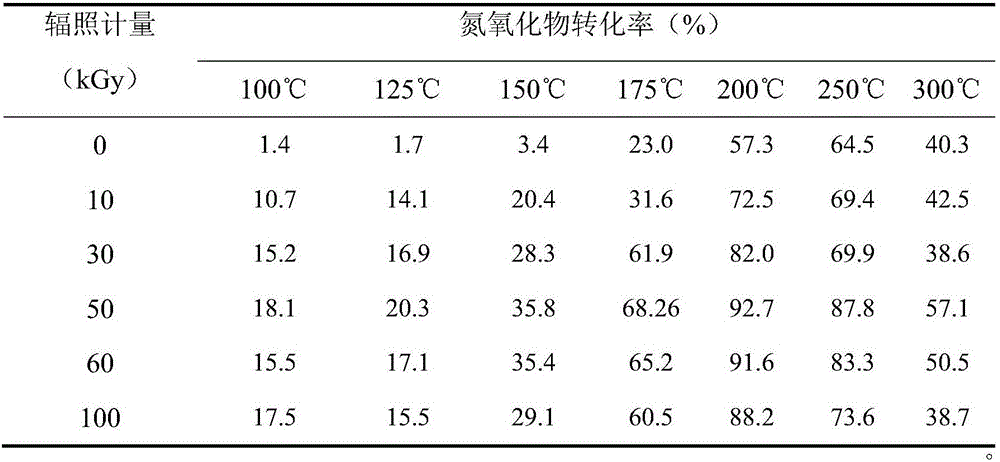

[0022] Irradiate 0.5% Pd / TiO under the condition of dose rate 50Gy / s and irradiation dose 10kGy 2 -Al 2 o 3 Catalyst preparation

[0023] a) On a rotary evaporator, 16.02 grams of aluminum isopropoxide was hydrolyzed at 90°C for 4 hours with deionized water, dilute nitric acid was added to form a transparent sol, and then 8.52 grams of tetrabutyl titanate was added to make TiO 2 and Al 2 o 3 The mass ratio is 2:8, stirred for 6 hours to form a gel;

[0024] b) Aging the gel obtained in step a) for 24 hours at room temperature, drying at 120°C for 12 hours, and finally roasting in a muffle furnace at 500°C for 4 hours to obtain TiO 2 -Al 2 o 3 ;

[0025] c) get the TiO obtained in step b) 2 -Al 2 o 3 In the three-necked flask, add 4.7ml of 0.1mol / L PdCl 2 Solution, 9.4×10 -3 mol polyvinylpyrrolidone (PVP) and 4.7×10 -3 mol polyethylene glycol solution and mix, pass through N 2 With protective gas and circulating condensed water, the temperature was gradually rais...

Embodiment 2

[0028] Irradiate 0.5% Pd / TiO under the condition of dose rate 50Gy / s and irradiation dose 50kGy 2 -Al 2 o 3 Catalyst preparation

[0029] a) Use deionized water on a rotary evaporator to hydrolyze 16.02 grams of aluminum isopropoxide at 90 ° C for 8 hours, add dilute nitric acid to form a transparent sol, and then add 8.52 grams of tetrabutyl titanate to make TiO 2 and Al 2 o 3 The mass ratio is 2:8, stirring for 10 hours, the formed gel;

[0030] b) Aging the gel obtained in step a) for 24 hours at room temperature, drying at 120°C for 10 hours, and finally roasting in a muffle furnace at 500°C for 4 hours to obtain TiO 2 -Al 2 o 3 ;

[0031] c) get the TiO obtained in step b) 2 -Al 2 o 3 In the three-necked flask, add 4.7ml of 0.1mol / L PdCl 2 Solution, 9.4×10 -3 mol polyvinylpyrrolidone (PVP) and 4.7×10 -3 mol polyethylene glycol solution and mix, pass through N 2 With protective gas and circulating condensed water, the temperature was gradually raised to 160°...

Embodiment 3

[0034] Irradiate 0.5% Pd / TiO under the condition of dose rate 50Gy / s and irradiation dose 100kGy 2 -Al 2 o 3 Catalyst preparation

[0035] a) On a rotary evaporator, 16.02 grams of aluminum isopropoxide was hydrolyzed at 90° C. for 4 hours with deionized water, dilute nitric acid was added to form a transparent sol, and then 8.52 grams of tetrabutyl titanate was added to make TiO 2 and Al 2 o 3 The mass ratio is 2:8, stirred for 6 hours to form a gel;

[0036] b) Aging the gel obtained in step a) for 24 hours at room temperature, drying at 120°C for 10 hours, and finally roasting in a muffle furnace at 450°C for 8 hours to obtain TiO 2 -Al 2 o 3 ;

[0037] c) get the TiO obtained in step b) 2 -Al 2 o 3 In the three-necked flask, add 4.7ml of 0.1mol / L PdCl 2 Solution, 9.4×10 -3 mol polyvinylpyrrolidone (PVP) and 4.7×10 -3 mol polyethylene glycol solution and mix, pass through N 2 With protective gas and circulating condensed water, the temperature was gradually r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com