Preparation method of core-shell cationic acrylic resin

A cationic acrylic, core-shell type technology, applied in the field of coatings, can solve the problems of changing the properties of polymer emulsions, hot stickiness, cold brittleness, and solvent resistance, and achieve the effects of reduced use, low toxicity, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

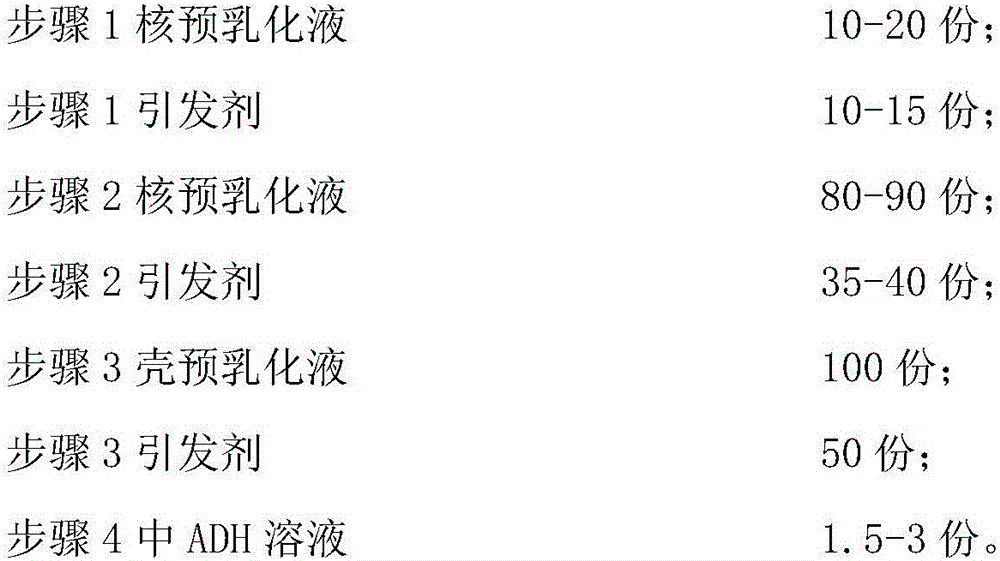

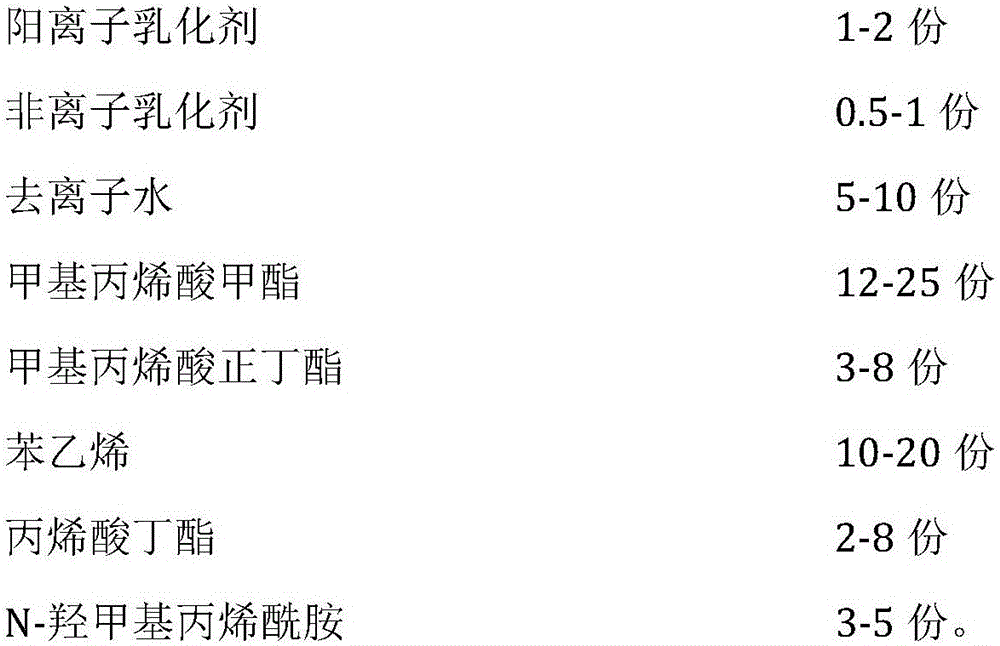

Method used

Image

Examples

Embodiment 1

[0034] Add 6g of deionized water, 0.28g of cetyltrimethylammonium chloride and 0.14g of LCN407 emulsifier to the beaker in turn, put it on a high-speed shear emulsifier and stir it at 150r / min to dissolve, and adjust the speed to 500r / min, then slowly add 6g methyl methacrylate, 12g styrene, 1.4g n-butyl methacrylate, 0.6g dimethylaminoethyl methacrylate mixed monomer into the beaker, and pre-emulsify for 1h. In the same manner as above, the shell pre-emulsion was prepared, wherein the shell components were: 6g deionized water, 0.28g cetyltrimethylammonium chloride and 0.14g LCN407; 3g methyl methacrylate, 5.8g Styrene, 1 g of n-butyl methacrylate, 0.6 g of dimethylaminoethyl methacrylate, 1.2 g of N-methylolacrylamide, 6.4 g of 2-ethylethyl acrylate, 2 g of diacetone acrylamide. Add another 30g of deionized water, 0.10g of cetyltrimethylammonium chloride and 0.05g of LCN407 to a 250mL four-neck flask in turn, place it in a constant temperature water bath at 75°C and stir even...

Embodiment 2

[0039] Add 6g of deionized water, 0.16g of cetyltrimethylammonium chloride and 0.32g of LCN407 emulsifier in sequence in the beaker, put it on a high-speed shear emulsifier and stir at 150r / min to dissolve, and adjust the speed after it is completely dissolved. To 500r / min, slowly add 10g of methyl methacrylate, 8g of styrene, 1.4g of 2-ethyl ethyl acrylate, 0.6g of N-methylolacrylamide mixed monomer into the beaker, and pre-emulsify for 1 hour. In the same manner as above, the shell pre-emulsion was prepared, wherein the shell components were: 6g deionized water, 0.16g cetyltrimethylammonium chloride and 0.32g LCN407; 5.4g methyl methacrylate, 3g n-butyl methacrylate, 1g styrene, 6.5g n-butyl acrylate, 1.2g dimethylaminoethyl methacrylate, 1.2g N-methylolacrylamide, 1.5g 2-ethyl ethyl acrylate, 2.2 g diacetone acrylamide. Add another 30g of deionized water, 0.16g of cetyltrimethylammonium chloride and 0.32g of LCN407 to a 250mL four-necked flask in turn, place it in a consta...

Embodiment 3

[0044] Add 6g of deionized water, 0.28g of cetyltrimethylammonium chloride and 0.14g of LCN407 emulsifier in sequence in the beaker, put it on a high-speed shear emulsifier and stir it at 150r / min to dissolve, and adjust the speed after it is completely dissolved. To 500r / min, slowly add 8.6g methyl methacrylate, 7g styrene, 2g n-butyl methacrylate, 1g n-butyl acrylate, 1.4g N-methylolacrylamide mixed monomer into the beaker, Pre-emulsify for 1h. In the same manner as above, the shell pre-emulsion was prepared, wherein the shell components were: 6g deionized water, 0.28g cetyltrimethylammonium chloride and 0.14g LCN407; 0.6g methyl methacrylate, 0.4 g styrene, 10g n-butyl acrylate, 1.2g dimethylaminoethyl methacrylate, 1.2g N-methylolacrylamide, 2g-2-ethylethyl acrylate, 2g diacetone acrylamide, 3.2g methylol acrylamide Acryloyloxypropyltrimethoxysilane, 0.6g glycidyl methacrylate. Add another 30g of deionized water, 0.10g of cetyltrimethylammonium chloride and 0.05g of LCN4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com