I-III-VI multi-component quantum dot preparation method based on ionic-liquid-assisted microwave synthesis, and product prepared according to preparation method

An I-III-VI, ionic liquid technology is applied in the preparation field of ionic liquid-assisted microwave synthesis of I-III-VI group multi-component quantum dots, which can solve the problems of increased cost and toxicity, low quantum dot yield, low reaction temperature, etc. problem, to achieve the effect of increasing the instantaneous nucleation rate, improving the fluorescence performance, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, a preparation method for ionic liquid-assisted microwave synthesis of group I-III-VI multi-element quantum dots, the steps are as follows:

[0028] (1) Dissolve 0.03mmol copper chloride and 0.03mmol indium chloride of water-soluble metal salt in 60ml deionized water to form a precursor mixture containing metal ions;

[0029] (2) Add 0.6 mmol glutathione, an organic ligand, to the above-mentioned precursor mixture to balance the activity of the metal cation, stir and dissolve, and adjust with NaOH to obtain a mixed solution with a pH value of 9.0;

[0030] (3) Add 0.6 mmol of ionic liquid 1-butyl-3-methylimidazolium tetrafluoroborate to the above mixed solution and mix evenly, then add sodium sulfide with an equimolar number of metal ions to obtain a reaction solution;

[0031] (4) Pour the above reaction solution into a polytetrafluoroethylene liner and place it in a commercially available microwave oven at low heat (120W) for microwave reaction for ...

Embodiment 2

[0034] In this embodiment, a preparation method for ionic liquid-assisted microwave synthesis of group I-III-VI multi-element quantum dots differs from Embodiment 1 in that:

[0035] (1) In the step (1), the water-soluble metal salt is 0.0067mmol copper chloride, 0.0467mmol indium chloride, 0.0067mmol zinc acetate;

[0036] (2) In the step (3), the ionic liquid is 0.012mmol 1-butyl-3 methylimidazolium bromide;

[0037] (3) In the step (4), the microwave reaction time is 40 minutes to obtain a Cu-In-Zn-S quaternary quantum dot solution.

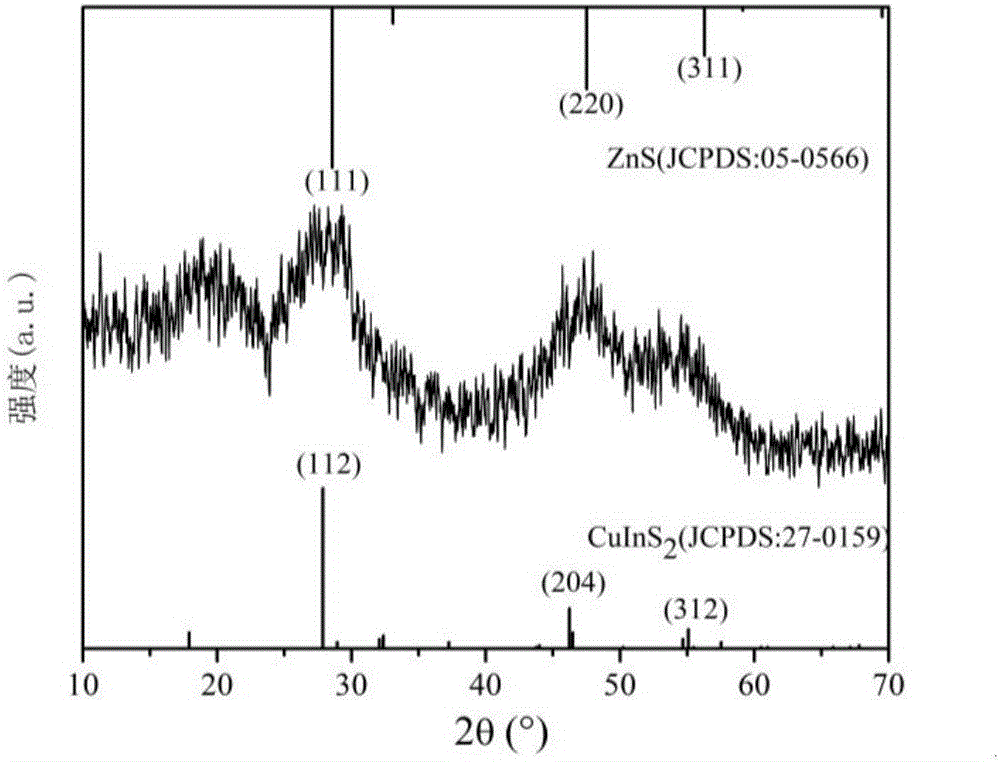

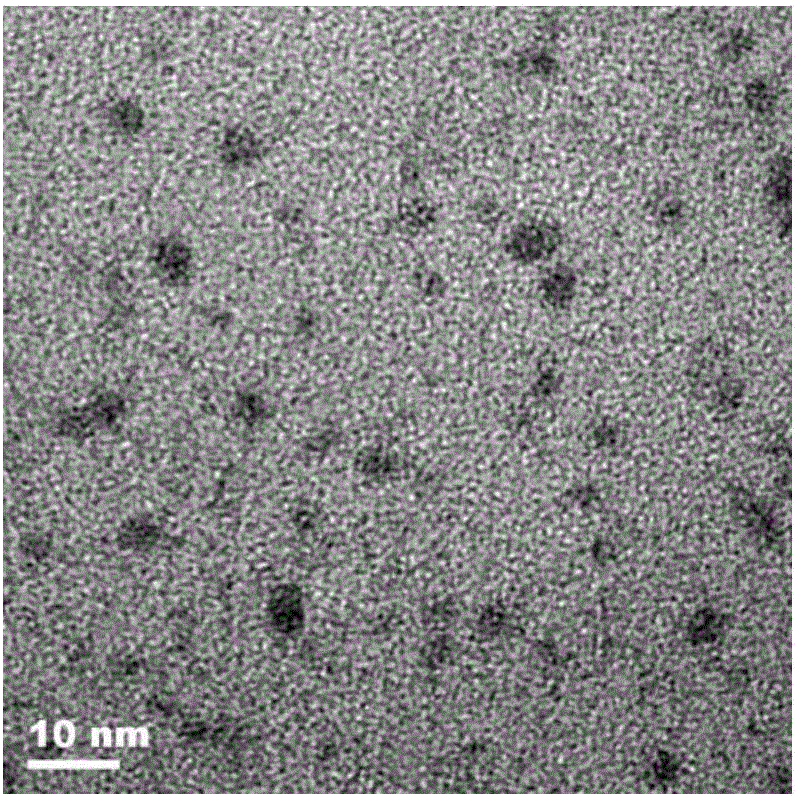

[0038] Such as figure 2 As shown, the multi-element quantum dots of the present embodiment are Cu-In-Zn-S quaternary quantum dots of tetragonal chalcopyrite structure, do not contain other impurity phases, and its particle size is about 4nm (see image 3 ), conforms to the size range of quantum dots, and has good dispersion.

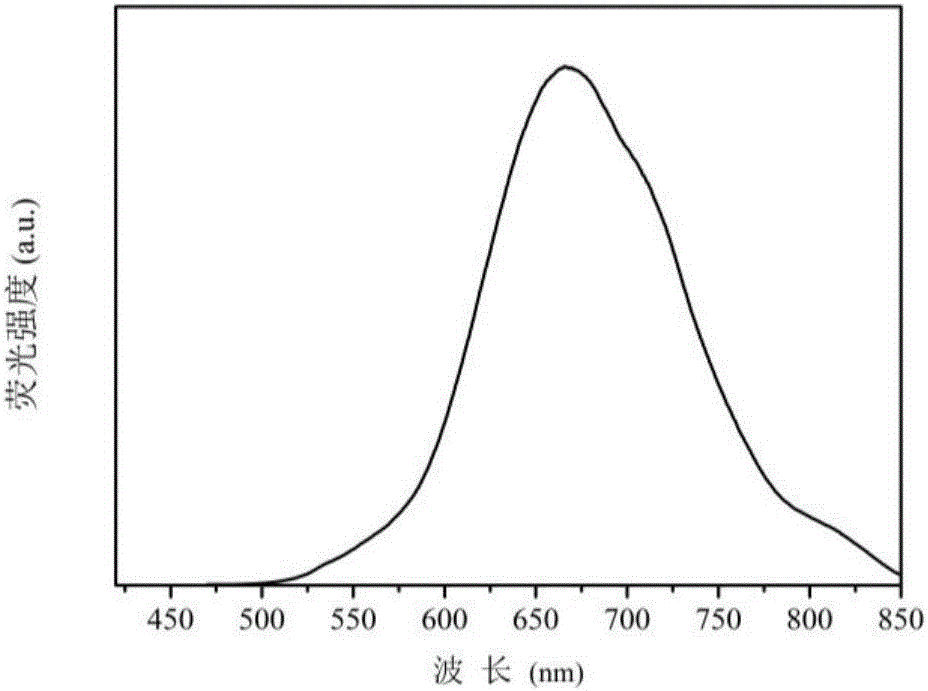

[0039] Such as Figure 4 As shown, this example is based on imidazolium bromide salt ionic liquid, and the obtain...

Embodiment 3

[0041] In this embodiment, a preparation method for ionic liquid-assisted microwave synthesis of group I-III-VI multi-element quantum dots differs from Embodiment 1 in that:

[0042] (1) In the step (1), the water-soluble metal salt is 0.03mmol copper chloride, 0.09mmol indium chloride, 0.3mmol zinc acetate;

[0043] (2) The consumption of organic ligand glutathione in step (2) is 4.2mmol;

[0044] (3) In the step (3), the ionic liquid is 12.6mmol 1-butyl-3 methylimidazolium chloride salt;

[0045] (4) Obtain Cu-In-Zn-S quaternary quantum dot solution.

[0046] Such as Figure 4 As shown, this embodiment is based on imidazolium chloride salt ionic liquid, and the obtained Cu-In-Zn-S quaternary quantum dots have an obvious luminescence peak at 647nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com