Special system and method for preparing pellets for calcium carbide semi-coke forming

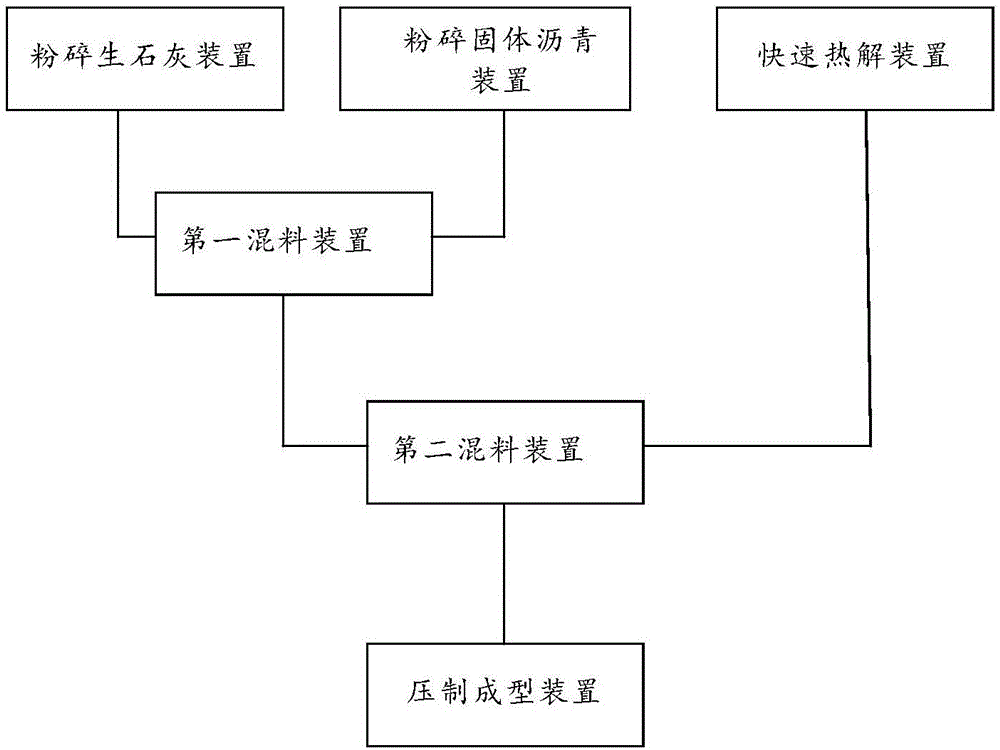

A special system, semi-coke technology, applied in the field of preparation of semi-coke molding balls for calcium carbide, can solve the problems of high cost, heavy pollution, complex process, etc., achieve low molding cost, reduce mixing difficulty, and simplify the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

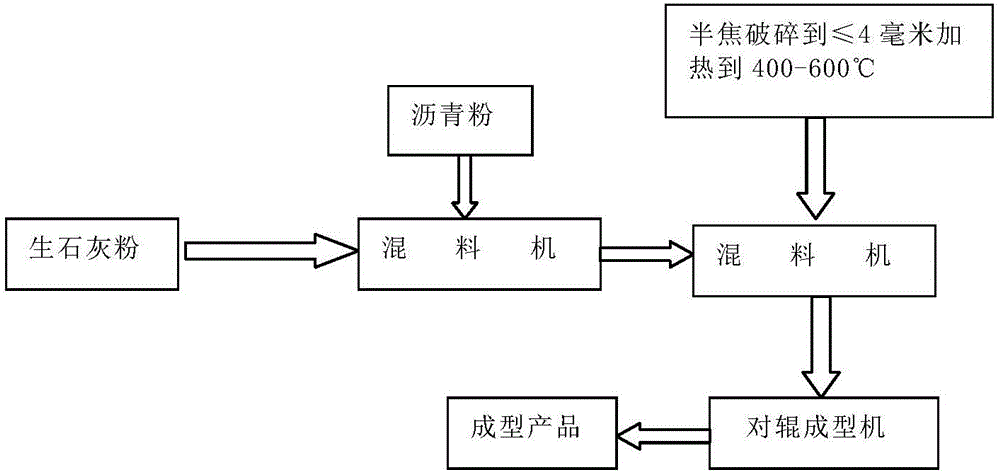

[0047] Crushing the semi-coke in the semi-coke crushing device to obtain semi-coke powder; crushing the quicklime in the quicklime crushing device to obtain quicklime powder; crushing the solid asphalt in the crushing solid asphalt device to obtain asphalt powder;

[0048] Main features of semi-coke: dry base fixed carbon content 79.64%, moisture content 3.21%, particle size ≤ 4mm;

[0049] Binder: medium temperature asphalt powder, particle size ≤ 1mm, softening point 109°C;

[0050] Quicklime powder: particle size ≤ 2mm or less;

[0051] Taking semi-coke as a benchmark, weigh 1kg of semi-coke powder, 1.5kg of quicklime powder, and 75 grams of asphalt powder, and first mix the quicklime powder and asphalt powder with the first mixing device (Eirich R02 mixer) for 5 minutes. Obtain the mixture; mix the mixture of 400 ℃ semi-coke, pitch and quicklime in the second mixing device (Eirich R02 mixer), and the mixing time is 3 minutes to obtain the final mixture; the final mixture T...

Embodiment 2

[0053] Crushing the semi-coke in the semi-coke crushing device to obtain semi-coke powder; crushing the quicklime in the quicklime crushing device to obtain quicklime powder; crushing the solid asphalt in the crushing solid asphalt device to obtain asphalt powder;

[0054] Main characteristics of semi-coke: dry base fixed carbon content 79.64%, moisture content 3.21%, particle size 4mm and below;

[0055] Binder: medium temperature asphalt powder, particle size below 1mm, softening point 109°C;

[0056] Based on the semi-coke, weigh 1kg of semi-coke powder, 1.5kg of quicklime powder, and 125 grams of asphalt powder, and first mix the quicklime powder and asphalt powder with the first mixing device (EIRICH R02 mixer) for 5 minutes Obtain the mixture, then mix the mixture of 400°C semi-coke, pitch and quicklime in the second mixing device (Ai Lixu R02 mixer), and the mixing time is 5 minutes to obtain the final mixture; the final mixture The material is quickly formed by a pair...

Embodiment 3

[0058] Crushing the semi-coke in the semi-coke crushing device to obtain semi-coke powder; crushing the quicklime in the quicklime crushing device to obtain quicklime powder; crushing the solid asphalt in the crushing solid asphalt device to obtain asphalt powder;

[0059] Main features of semi-coke: dry base fixed carbon content 79.64%, moisture content 3.21%, particle size ≤ 4mm;

[0060] Binder: medium temperature asphalt powder, particle size ≤ 1mm, softening point 109°C;

[0061] Quicklime powder: particle size ≤ 2mm or less;

[0062] Taking semi-coke as a benchmark, weigh 1kg of semi-coke powder, 1.5kg of quicklime powder, and 50 grams of asphalt powder, and first mix the quicklime powder and asphalt powder with the first mixing device (Eirich R02 mixer) for 5 minutes. Obtain the mixed material; mix the mixture of 500 ℃ semi-coke, pitch and quicklime in the second mixing device (Ai Lixu R02 mixer), and the mixing time is 5 minutes to obtain the final mixed material; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com