Method for in-situ construction of multistage nanometer topological structure on titanium-based implant surface based on salt corrosion

A topological structure and implant technology, applied in prosthesis, medical formula, medical science, etc., can solve the problems of limited nanostructure control ability, cumbersome processing process, and high processing cost, and achieve the promotion of selective adsorption, application safety, and corrosion resistance. The effect of mild process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] (1) Measure 20ml of pure water, 6ml of 48% HF and 4ml of 48% HNO 3 , Dilute 5 times after mixing to prepare pickling solution. Take an appropriate amount of pickling solution and put it into a beaker, put the titanium alloy into it and wash it for 30 seconds, then discard the obtained light yellow-green liquid, and ultrasonically clean it three times with ultrapure water.

[0074] (2) Weigh 0.663g of (NH 4 ) 2 HPO 4 Dissolve in 10ml deionized water, dilute 10 times to obtain 0.05mol / L (NH 4 ) 2 HPO 4 Put the solution in a closed beaker, immerse the cleaned titanium alloy in it, seal it, put it in an oven, and keep it warm at 60°C for 4h. The obtained titanium alloy was ultrasonically cleaned with ultrapure water for 10 min.

[0075] (3) Place the sample in a muffle furnace for soaking at 500°C for 1 h, and after natural cooling, use ultrapure water to ultrasonically clean it for 3 min.

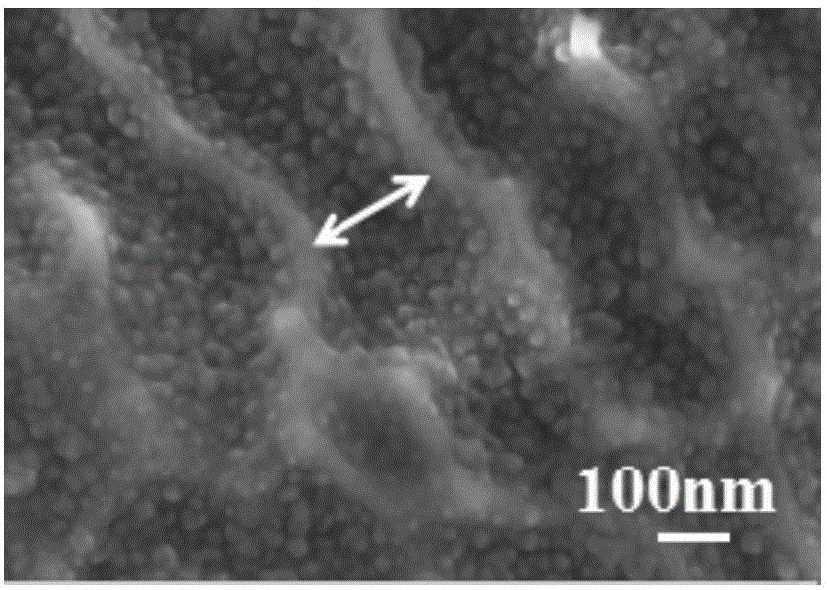

[0076] figure 1The surface morphology of the titanium alloy after treatmen...

Embodiment 2

[0078] (1) Measure 20ml of pure water, 6ml of 48% HF and 4ml of 48% HNO 3 , mixed and diluted 10 times to prepare pickling solution. Take an appropriate amount of pickling solution and put it into a beaker, put titanium into it and wash it for 2 minutes, then discard the obtained light yellow-green liquid, and clean it three times with ultrapure water ultrasonically.

[0079] (2) Weigh 2.641g of (NH 4 ) 2 HPO 4 Dissolve in 10ml deionized water to obtain 2mol / L (NH 4 ) 2 HPO 4 Put the solution in a closed beaker, immerse the cleaned titanium in it, seal it, put it in an oven, and keep it warm at 40°C for 24h. The obtained titanium was ultrasonically cleaned with ultrapure water for 10 min.

[0080] (3) The sample was placed in a muffle furnace for soaking at 500°C for 6 hours, and after natural cooling, it was ultrasonically cleaned with ultrapure water for 3 minutes.

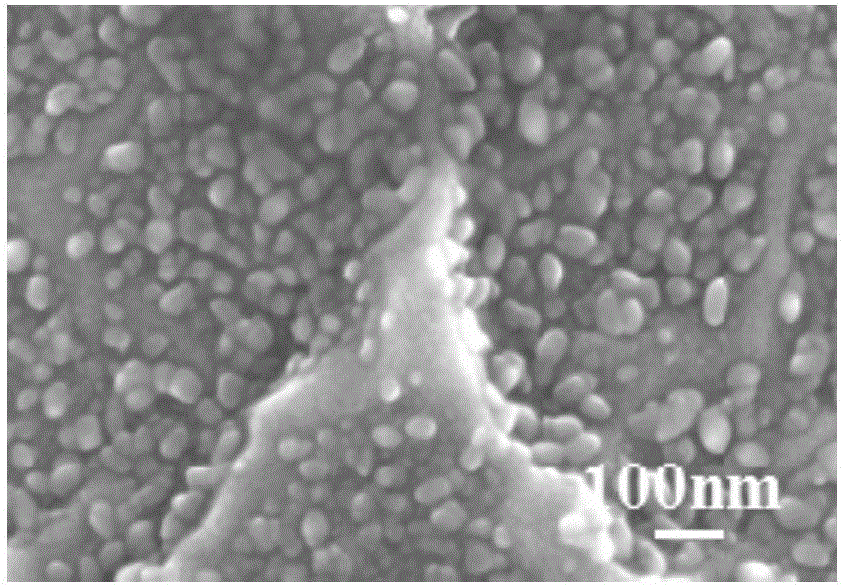

[0081] figure 2 It is the topography of titanium surface after treatment in this embodiment. It ca...

Embodiment 3

[0083] (1) Measure 20ml of pure water, 6ml of 48% HF and 4ml of 48% HNO 3 , Diluted 30 times after mixing to prepare pickling solution. Take an appropriate amount of pickling solution and put it into a beaker, put the titanium alloy into it and wash it for 5 minutes, then discard the obtained light yellow-green liquid, and clean it three times with ultrapure water ultrasonically.

[0084] (2) Weigh 5.282g of (NH 4 ) 2 HPO 4 Dissolve in 10ml deionized water to obtain 4mol / L (NH 4 ) 2 HPO 4 Put the solution in a closed beaker, immerse the cleaned titanium alloy in it, seal it, put it in an oven, and keep it warm at 100°C for 0.5h. The obtained titanium alloy was ultrasonically cleaned with ultrapure water for 10 min.

[0085] (3) Place the sample in a muffle furnace for soaking at 500°C for 0.5 h, and after natural cooling, ultrasonically clean it with ultrapure water for 3 min.

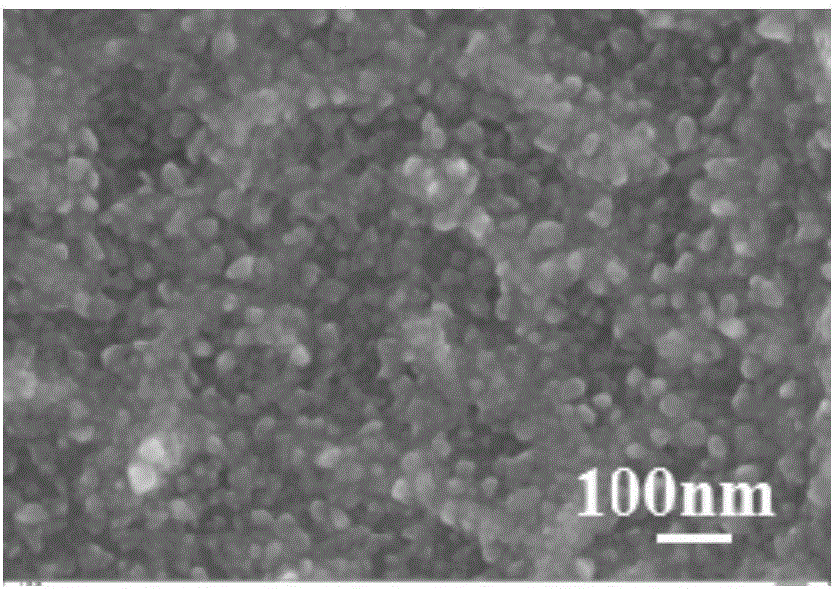

[0086] image 3 The titanium alloy surface morphology after the treatment of this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com